Isolated protein powder prepared by euphausia superba powder

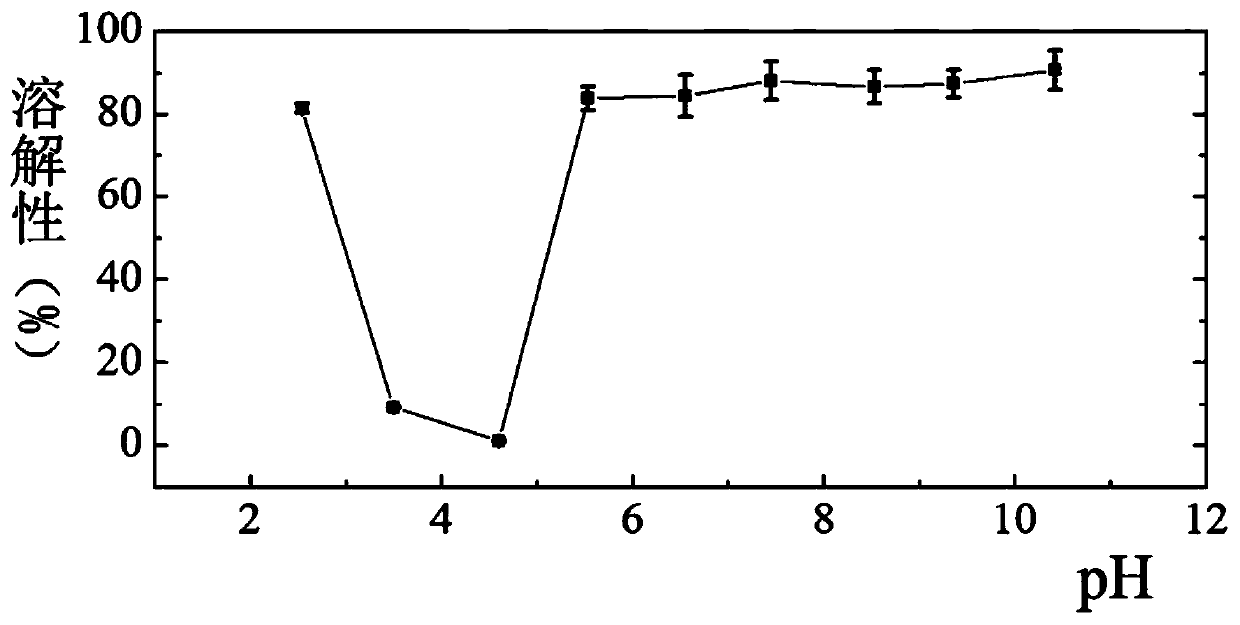

A technology of Antarctic krill powder and protein isolate, which is applied in the field of protein isolate powder, can solve the problem of high salt content and achieve the effects of high protein content, good solubility and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

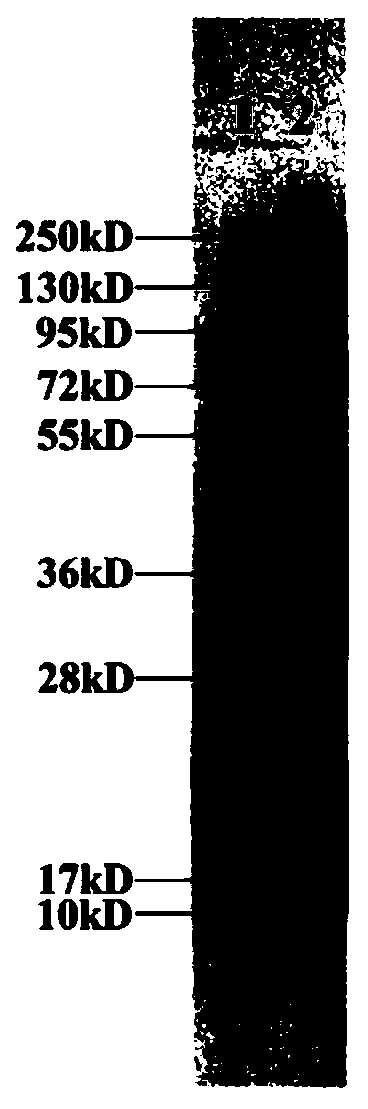

Examples

Embodiment 1

[0039] 1) Take 10 kg of Antarctic krill powder, add 120 L of 90% ethanol to the krill powder, stir in the reaction kettle at room temperature for 10 hours, centrifuge to take the precipitate, and dry it in vacuum to obtain defatted krill powder;

[0040] The protein content in Antarctic krill powder is 60-65%, the lipid content is 8-13%, the ash content is 10-15%, the fluorine content is 1800-2200mg / kg, and the defatted krill powder obtained in step 1) is medium-fat Quality content is less than 2%.

[0041] The determination method of protein content refers to the Kjeldahl method in GB5009.5-2010 "National Standard - Determination of Protein in Food"; the determination method of ash content refers to GB5009.4-2010 "National Standard - Determination of Ash Content in Food"; The determination method of the content refers to the fluoride ion selective electrode method in GB / T5009.18-2003 "National Standard - Determination of Fluorine in Food"; the determination method of the tota...

Embodiment 2

[0055] 1) Take 10 kg of Antarctic krill powder, add 80 L of 95% ethanol to the krill powder, stir in the reaction kettle for 10 hours, centrifuge to take the precipitate, and dry it in vacuum to obtain defatted krill powder;

[0056] The lipid content in the defatted krill powder is less than 2%, and the determination method of the total lipid content adopts the chloroform methanol method.

[0057] 2) Take 5 kg of defatted krill powder, add 50 L of 0.3M acetic acid solution to it, stir in the reaction kettle at room temperature for 4 hours, centrifuge at 5000 r / min to collect the precipitate, wash the precipitate repeatedly with distilled water until neutral, and obtain precipitate A;

[0058] 3) Add 50L of 0.15M sodium hydroxide solution to the precipitate A, stir in a reaction kettle at 40°C for 40min, and centrifuge to get the supernatant A;

[0059] 4) Add 2M HCl to the supernatant A, adjust the pH of the supernatant A to 4.6, let stand at 4°C for 30 minutes, and centrifug...

Embodiment 3

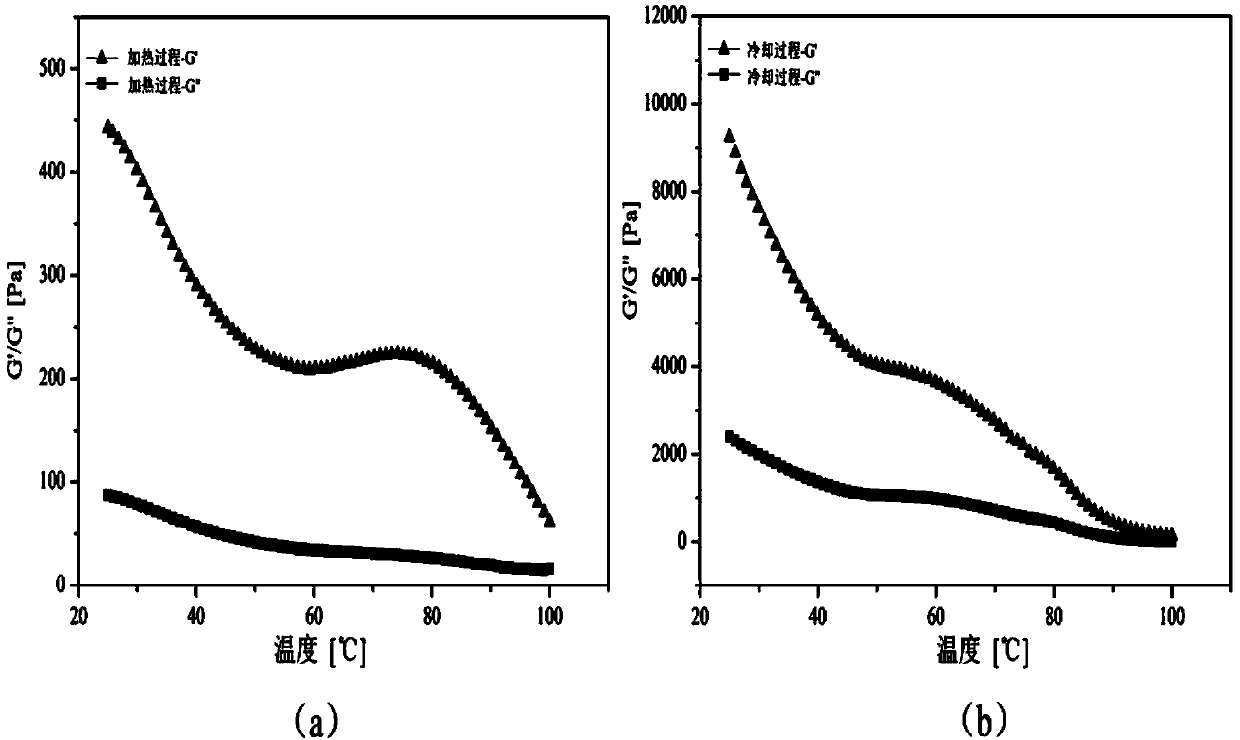

[0066] Antarctic krill protein isolate powder in the present invention has low-fat, low-salt and thermoreversible gel properties, and can be used in food processing as a fat substitute, such as: mayonnaise, processed meat, ice cream, cheese, sauce, dessert, Baked food can be used to replace part or all of fat, effectively regulating and controlling fat intake.

[0067] Take 1kg of Antarctic krill protein isolate, add 10L of water to the protein isolate powder, stir and mix well, then let the protein isolate solution stand at 4°C for 12h; Mix evenly, heat-treat the mixed solution for 30 minutes at 80°C (without stirring during the heat treatment), immediately ice-bath for 10 minutes after heat treatment, and after cooling, use a homogenizer to micronize at 12000r / min for 15 minutes, namely The fat substitute gel is obtained, and the fat substitute powder is obtained after the fat substitute gel is freeze-dried. The results of use show that the protein isolate powder prepared i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com