Method and equipment for preparing long carbon chain olefins by use of natural alcohols or esters

A technology for long-carbon chain olefins and natural alcohols, applied in chemical instruments and methods, in the production of hydrocarbons and hydrocarbons from oxygen-containing organic compounds, etc., can solve the problems of low selectivity, high reaction temperature, and many side reactions, etc. The effect of saving petrochemical resources, reducing reaction temperature and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

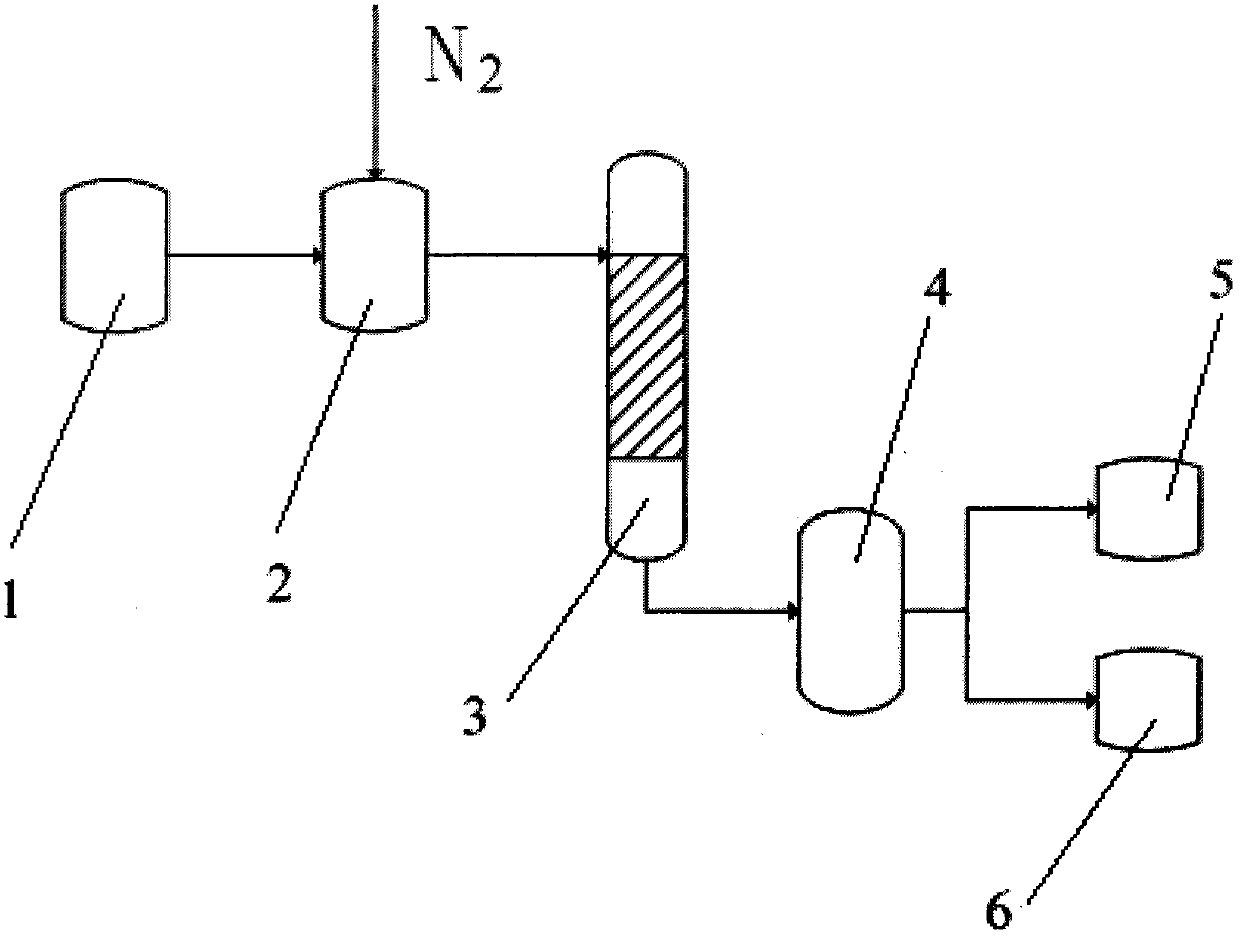

Method used

Image

Examples

Embodiment 1

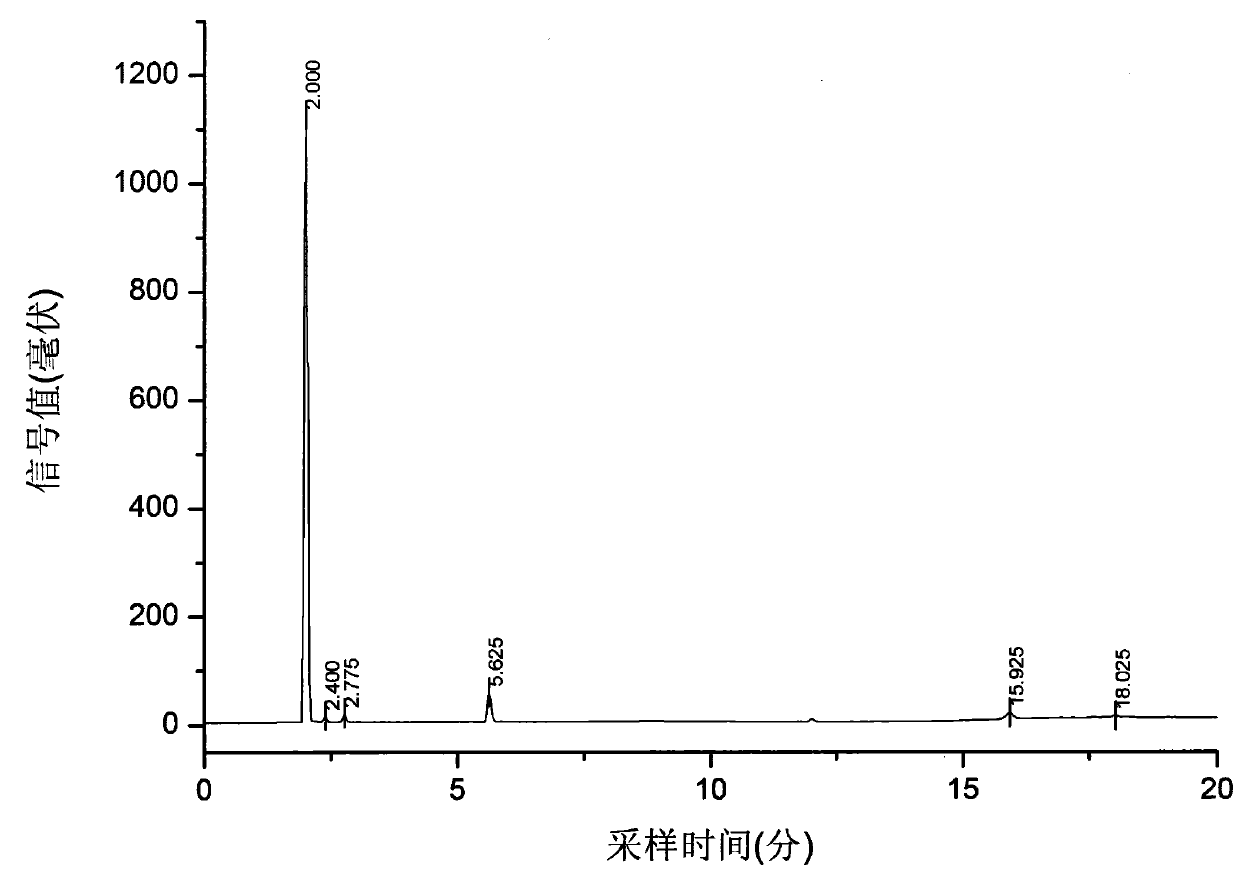

[0029] Anhydrous aluminum trifluoride (AlF 3 ) 600g, add 400g gamma-alumina (Al 2 o 3 ) and 50g of silicon oxide were mixed uniformly, and dilute nitric acid was added to the uniformly mixed material, extruded into strips on an extruder, placed in an oven to dry at 120°C for 8hrs, transferred to a muffle furnace for 3hrs at 500°C, and then cooled naturally to The catalyst is obtained at room temperature, then pulverized and sieved to obtain a catalyst with a particle size of about 2 mm for use; the catalyst is used in the dehydration reaction of n-octanol or n-octyl ester, the reaction pressure is 0.105 MPa, the reaction temperature is 290 ° C, and the liquid space velocity is 0.3 / hour, after continuous reaction for 12 hours, the conversion rate of n-octanol or n-octyl ester detected by gas chromatography is 95.5%, and the selectivity of n-octene in the olefin product is 98.2%, and the gas chromatogram is shown in figure 2 shown.

Embodiment 2

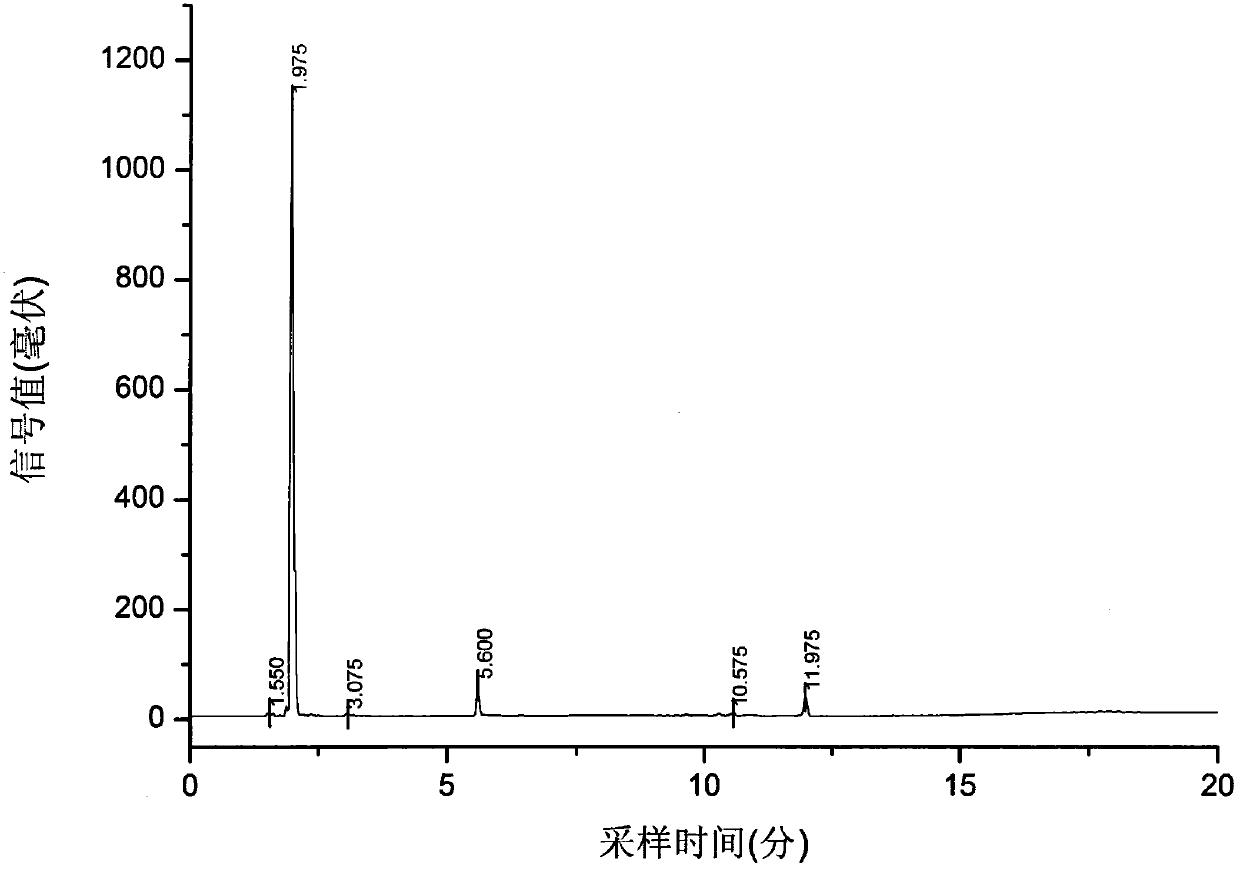

[0031] Anhydrous gallium trifluoride (GaF 3 ) 600g, add 400g gamma-alumina (Al 2 o 3 ) and 50g of silicon oxide were mixed uniformly, dilute nitric acid was added to the uniformly mixed material and extruded into strips on an extruder, placed in an oven to dry at 120°C for 8hrs, transferred to a muffle furnace for 3hrs at 450°C, and then cooled naturally to The catalyst is obtained at room temperature, then pulverized and sieved to obtain a catalyst with a particle size of about 2mm for use; the catalyst is used for the reaction of 2-octanol or 2-octyl ester, the reaction pressure is 0.1MPa, the reaction temperature is 310°C, and the liquid space velocity is 0.4 / hour, after continuous reaction for 12 hours, the conversion rate of 2-octyl alcohol or 2-octyl ester detected by gas chromatography is 97.5%, and the selectivity of 2-octene in the olefin product is 98.0%, and the gas chromatogram is shown in image 3 shown.

Embodiment 3

[0033] Chromium trifluoride (CrF 3 ) 600g, add 400g η-alumina (Al 2 o 3 ) mixed uniformly, dilute nitric acid was added to the uniformly mixed material and extruded into strips on an extruder, placed in an oven to dry at 120°C for 8hrs, transferred to a muffle furnace for 3hrs at 450°C and then naturally cooled to room temperature to obtain a catalyst. Then pulverize and sieve to obtain a catalyst with a particle size of about 2 mm for use; the catalyst is used for the n-decyl ester reaction, the reaction pressure is 0.06 MPa, the reaction temperature is 305 ° C, and the liquid space velocity is 0.35 / hour. After 12 hours of continuous reaction , the conversion rate of n-decyl ester detected by gas chromatography is 97.0%, and the selectivity of n-decene in the olefin product is 98.5%, and the gas chromatogram is shown in Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com