Hydrophobic oleophylic modified synthetic mica and preparation method thereof

A technology for synthesizing mica and hydrophobic and lipophilic, which is applied in the field of mica, can solve problems such as difficulty in controlling the uniformity of product quality, difficulty in mixing uniform surface treatment agents, and high energy consumption costs, and achieve uniform hydrophobic and lipophilic effects, good uniformity, and The effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

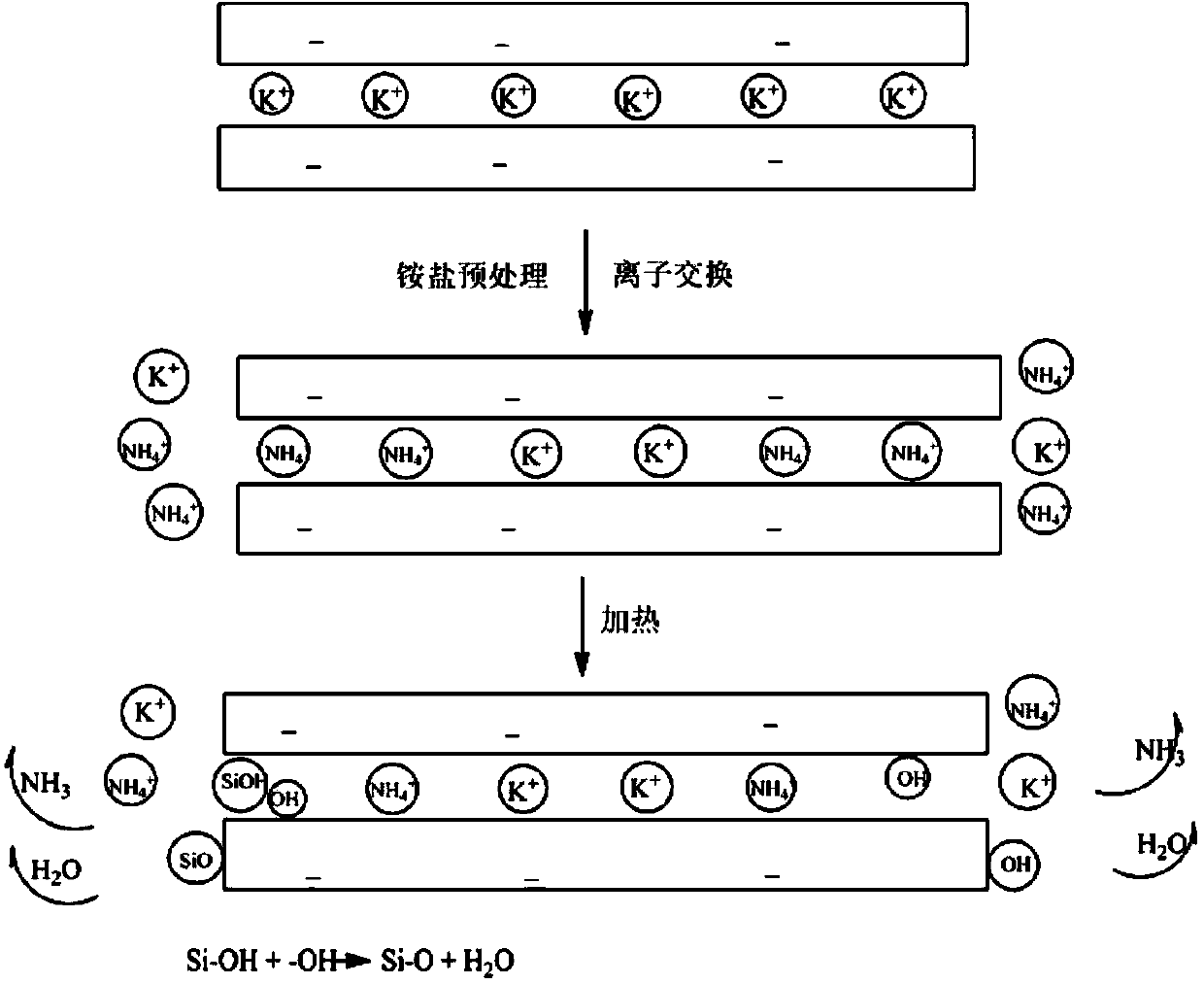

Method used

Image

Examples

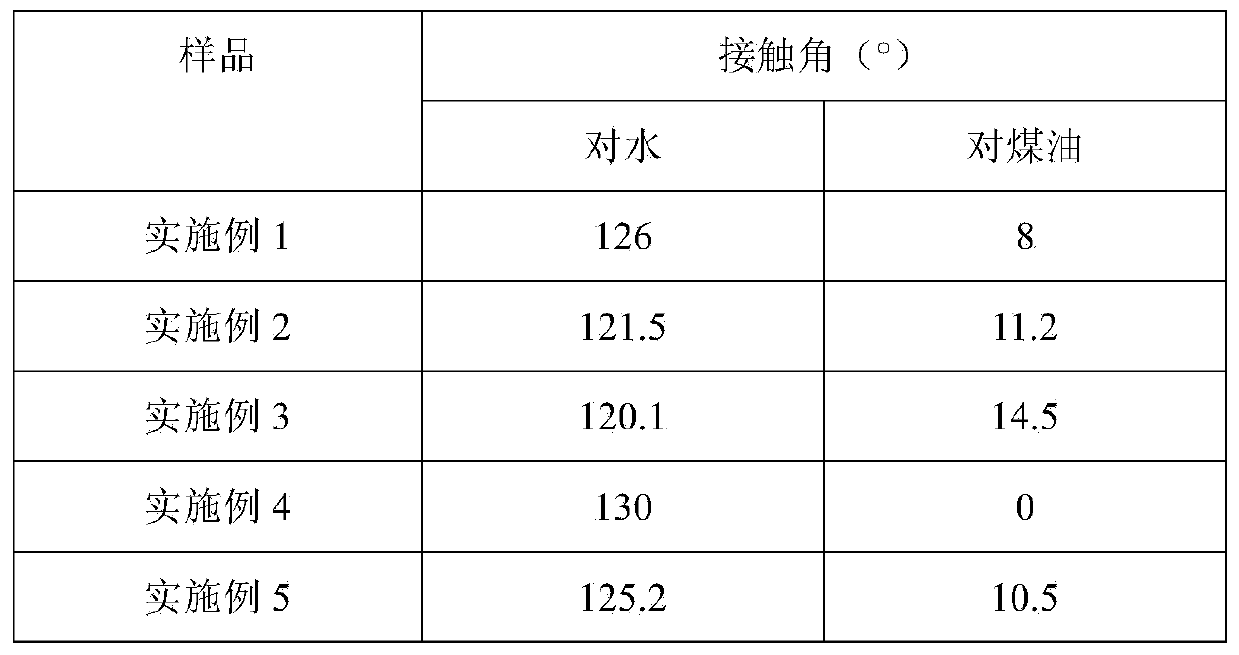

Embodiment 1

[0032] The first step, in parts by mass, add 5 parts of synthetic mica and 45 parts of water in the reactor, stirring at room temperature (rotating speed is 200rpm) for 10 minutes;

[0033] The second step, in parts by mass, adds 5.6 parts of ammonium bicarbonate to the reactor described in the first step, and adopts ultrasonic dispersion treatment for 10 minutes at room temperature (ultrasonic frequency and power are respectively 40kHz and 350W), so that the synthetic mica Uniform contact between particles and ammonium bicarbonate molecules for ion exchange to occur;

[0034] In the third step, in parts by mass, add 0.3 parts of hexadecyltrimethoxysilane and 2.7 parts of methanol solution in the reactor, and use ultrasonic dispersion for 20 minutes at room temperature (ultrasonic frequency and power are 50kHz and 450W respectively) , making the ion-exchanged synthetic mica particles contact with hexadecyltrimethoxysilane molecules uniformly, and then carry out solid-liquid se...

Embodiment 2

[0037] In the first step, in parts by mass, 10 parts of synthetic mica and 90 parts of water are added to the reactor, and stirred at room temperature for 5 minutes (rotating speed is 250rpm);

[0038] In the second step, add 11.2 parts of ammonium bicarbonate to the reactor described in the first step, and use ultrasonic dispersion treatment for 10 minutes at room temperature (ultrasonic frequency and power are respectively 40kHz and 350W), so that the synthetic mica particles and ammonium bicarbonate molecules Uniform contact between them for ion exchange to occur;

[0039] In the third step, add 0.5 parts of dodecyltrimethoxysilane and 4.5 parts of methanol solution in the reactor, and use ultrasonic dispersion treatment for 10 minutes at room temperature (ultrasonic frequency and power are 50kHz and 450W respectively), so that ion exchange occurs The synthetic mica particles are evenly contacted with dodecyltrimethoxysilane molecules, and then solid-liquid separation is ca...

Embodiment 3

[0042] In the first step, in parts by mass, 7 parts of synthetic mica and 60 parts of water are added to the reactor, and stirred at room temperature for 8 minutes (rotating speed is 150rpm);

[0043] In the second step, add 6.8 parts of ammonia water to the reactor described in the first step, and adopt ultrasonic dispersion treatment for 15 minutes at room temperature (ultrasonic frequency and power are respectively 40kHz and 300W), so that the uniform contact between the synthetic mica particles and the ammonia water molecules for ion exchange to occur;

[0044] In the third step, add 0.5 parts of octyltriethoxysilane and 4.5 parts of ethanol solution in the reactor, and use ultrasonic dispersion treatment for 25 minutes at room temperature (ultrasonic frequency and power are respectively 50kHz and 450W), so that the ion-exchanged Synthetic mica particles are uniformly contacted with octyltriethoxysilane molecules, and then solid-liquid separation is performed to obtain a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com