Water-based primer and its preparation method and application

A primer, water-based technology, applied in the field of water-based primer and its preparation, can solve the problems of low production cost, low gloss, and many surface defects of the coating film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

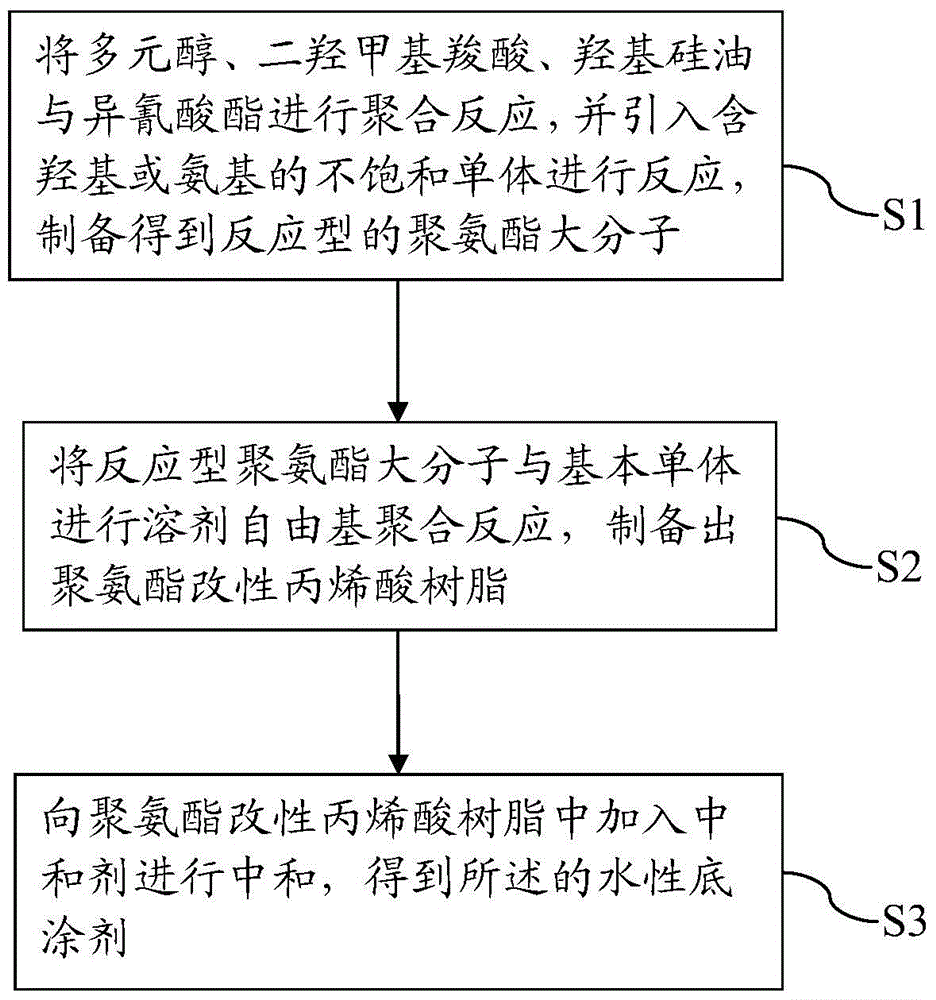

[0063] The preparation method of water-based primer of the present invention comprises the steps:

[0064] S1. Add polymer polyol, dimethylol carboxylic acid, and hydroxyl silicone oil to the first reaction kettle, vacuum dry, dehydrate, cool down, add solvent to adjust viscosity, stir evenly, add isocyanate, and carry out polymerization reaction under catalytic conditions , then dropwise add a polymerization inhibitor, an unsaturated monomer containing a hydroxyl group or an amino group, and an alcohol solvent, and continue the reaction to obtain a reactive polyurethane macromolecule;

[0065] S2. Add part of the reaction solvent to the second reaction kettle, heat, then add the reactive polyurethane macromolecule, basic monomer, molecular weight regulator, initiator and remaining solvent dropwise into the second reaction kettle, and add dropwise After completion, heat preservation, then gradually add the remaining initiator, after heating up, heat preservation, to obtain a s...

Embodiment 1

[0101] Add 60 parts of aromatic polyester diols with a molecular weight of 1000, 5 parts of bismethylol propionic acid, and 5 parts of a molecular weight of 5000 The dihydroxy silicone oil was vacuum-dried and dehydrated at 120°C for 2 hours, and then cooled to 60°C. Add 20 parts of acetone to adjust the mixture to an appropriate viscosity, and stir evenly. Then add 34.21 parts of toluene diisocyanate, and add 0.1 part of dibutyltin dilaurate, stir and react for 1 hour, then raise the temperature to 80°C, and continue the reaction for 2 hours. Then cool to 55°C, add 0.08 parts of methoxyphenol, 5.90 parts of isopropanol, and 12.80 parts of hydroxyethyl methacrylate, drop them in 20 minutes, and keep the reaction for 2 hours. Then raise the temperature to 65° C. and keep it warm for 1 hour, and then cool down to room temperature to obtain reactive aromatic polyester polyurethane.

[0102] Add 40 parts of isopropanol and 25 parts of propylene glycol methyl ether to a polymeriz...

Embodiment 2

[0106] Add 60 parts of aromatic polyester diols with a molecular weight of 2000, 5 parts of bismethylol propionic acid, and 4 parts of a molecular weight of 18000 Hydroxy silicone oil, vacuum-dried and dehydrated at 120°C for 2 hours, and then cooled to 60°C. Add 20 parts of methyl ethyl ketone to adjust to proper viscosity, and stir evenly. Then add 29.98 parts of isophorone diisocyanate, and add 0.15 parts of dibutyltin dilaurate, stir and react for 1 hour, then raise the temperature to 80°C, and continue the reaction for 2 hours. Then cool to 45°C, add 0.15 parts of 2,6-di-tert-butyl-p-cresol, 4.05 parts of isopropanol, and 4.80 parts of acrylamide, add dropwise in 20 minutes, and keep warm for 2 hours. Then raise the temperature to 60°C, keep it warm for 2 hours, and finally cool down to room temperature to obtain reactive aromatic polyester polyurethane.

[0107] Add 50 parts of isopropanol and 20 parts of propylene glycol ethyl ether into a polymerization reactor equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com