Immobilized nano porous BiFeO3 and preparation method thereof

A nano-porous and nano-carbon fiber technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., to achieve the effects of controllable shape, good orientation, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

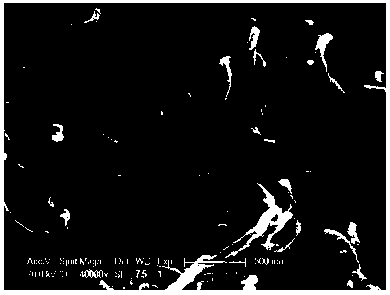

Image

Examples

Embodiment 1

[0033] An Immobilized Nanoporous BiFeO 3 The material is prepared by a method comprising the steps of:

[0034] (1), in the macro matrix material SiO 2 Synthesis of carbon nanofibers on rod-shaped fibers;

[0035] ①. Preparation of NiO / macroscopic matrix material SiO by impregnation method 2 Rod Fiber Monolith Catalyst

[0036] 0.2 g of macroscopic matrix material SiO2 The rod-shaped fibers were impregnated with Ni(NO 3 ) 2 .6H 2 O in ethanol solution, then vacuum filtered and dried at 110°C to remove the macroscopic matrix material SiO 2 Excess Ni(NO 3 ) 2 .6H 2 O solution, then put into the constant temperature zone of the quartz reaction tube with a length of 100 cm and a diameter of 6 cm to control the temperature at 300 ° C to obtain NiO / macroscopic matrix material SiO 2 Rod-shaped fiber monolithic catalyst;

[0037] The NiO / macro matrix material SiO obtained above 2 Rod-shaped fiber monolithic catalyst, calculated by mass ratio, that is, NiO: macroscopic matr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com