Energy-saving and environmental-friendly ceramic transparent glaze and preparation method thereof

An energy-saving, environmentally friendly, transparent glaze technology, applied in the field of daily-use ceramics, can solve problems such as hindering the rapid development of daily-use ceramics, potential safety hazards that easily pollute the environment, failing to meet environmental protection requirements, etc. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

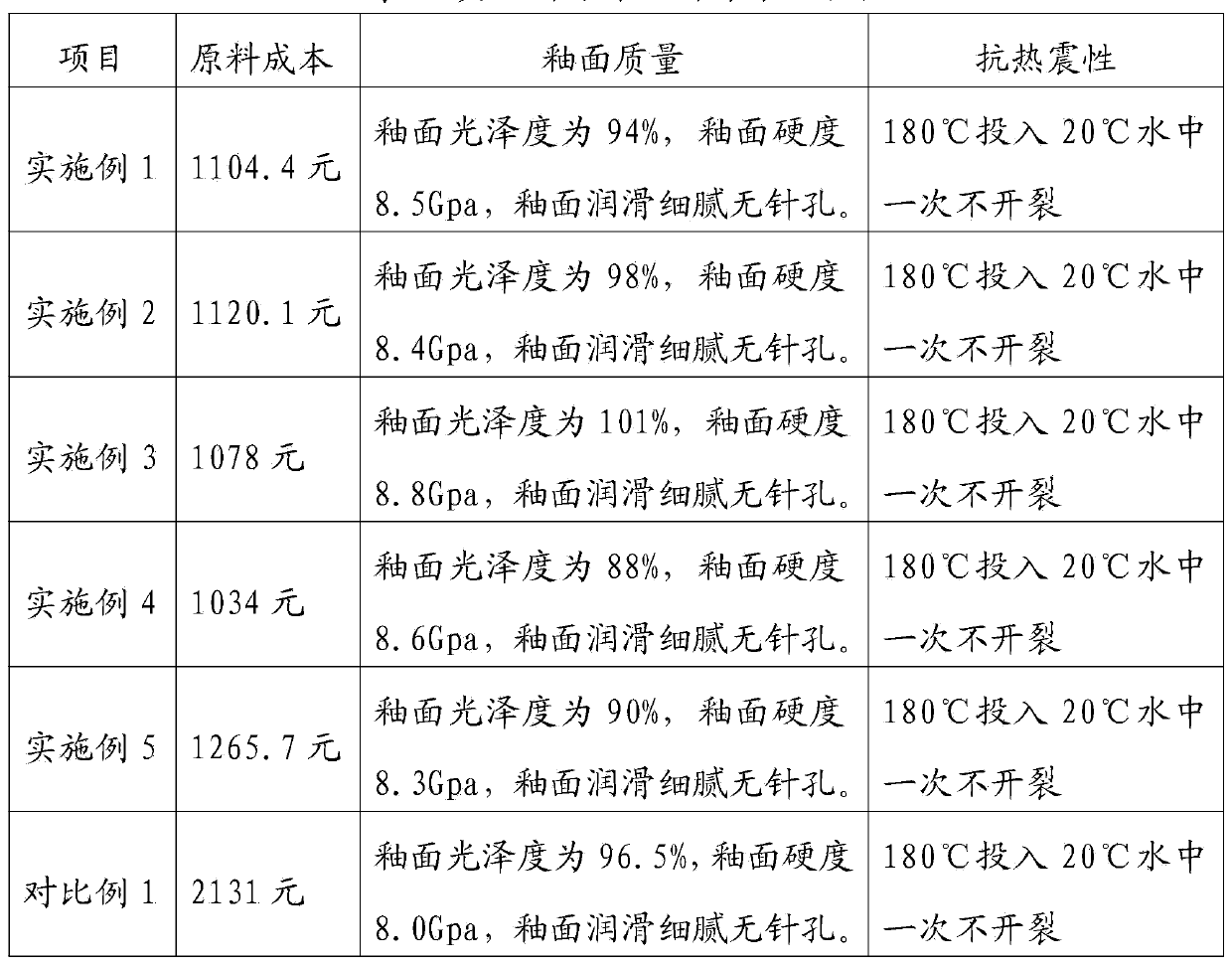

Examples

Embodiment 1

[0024] An energy-saving and environment-friendly ceramic transparent glaze, which is made of the following raw materials by weight percentage: 6% kaolin, 7% potassium feldspar powder, 8% magnesia waste porcelain powder, 10% quartz powder, 53% albite powder, and calcite powder 10%, zinc oxide 2%, strontium carbonate 4%.

[0025] The preparation method comprises the following steps: first, processing the stone raw materials potassium feldspar, albite, quartz and magnesia porcelain waste into a powder that passes at least 8 mesh sieves; weighing 60 kg of kaolin powder, 70 kg of potassium feldspar powder, magnesium Porcelain waste porcelain powder 80kg, quartz powder 100kg, albite powder 530kg, calcite powder 100kg, zinc oxide 20kg, strontium carbonate 40kg; put all raw materials into a ball mill equipped with a grinding body, add a certain amount of water to control the specific gravity of the glaze slurry At 1.70g / 100ml, ball mill until the particle diameter is less than 0.061mm...

Embodiment 2

[0027] An energy-saving and environment-friendly ceramic transparent glaze, which is made of the following raw materials by weight percentage: kaolin 5%, potassium feldspar powder 8%, magnesia porcelain waste porcelain powder 7%, quartz powder 11%, albite powder 50%, calcite powder 12%, zinc oxide 2%, strontium carbonate 5%.

[0028] The preparation method comprises the following steps: first, processing the stone raw materials potassium feldspar, albite, quartz and magnesia porcelain waste into a powder that passes at least 8 mesh sieves; weighing 50 kg of kaolin powder, 80 kg of potassium feldspar powder, magnesium Porcelain waste porcelain powder 70kg, quartz powder 110kg, albite powder 500kg, calcite powder 120kg, zinc oxide 20kg, strontium carbonate 50kg; put all raw materials into a ball mill equipped with a grinding body, add a certain amount of water to control the specific gravity of the glaze slurry At 1.67g / 100ml, ball mill until the particle diameter is less than 0...

Embodiment 3

[0030] An energy-saving and environment-friendly ceramic transparent glaze, which is made of the following raw materials by weight percentage: 4.5% of kaolin, 7% of potassium feldspar powder, 10% of magnesia waste porcelain powder, 10.5% of quartz powder, 52% of albite powder, and calcite powder 10%, zinc oxide 2%, strontium carbonate 4%.

[0031] The preparation method comprises the following steps: firstly processing the stone raw materials potassium feldspar, albite, quartz and magnesia porcelain waste into a powder that passes at least 8 mesh sieves; weighing 45 kg of kaolin powder, 70 kg of potassium feldspar powder, magnesium Porcelain waste porcelain powder 100kg, quartz powder 105kg, albite powder 520kg, calcite powder 100kg, zinc oxide 20kg, strontium carbonate 40kg; put all raw materials into a ball mill equipped with a grinding body, add a certain amount of water to control the specific gravity of the glaze slurry At 1.71g / 100ml, ball mill until the particle diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com