Ecological laundry detergent

A kind of laundry detergent and ecological technology, applied in the field of ecological laundry detergent, can solve the problems of poor detergency and other problems, and achieve the effect of strong detergency, low foam and good environmental compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of ecological laundry detergent among the present invention, it may further comprise the steps:

[0023] (1) Slowly add coconut oil acyl diethanolamine into a beaker filled with 30 parts of water under rapid stirring.

[0024] (2) Mix methyl p-hydroxybenzoate, propyl p-hydroxybenzoate and water into the beaker according to the dosage required by the formula, and stir evenly.

[0025] (3) Add amino acid-based polyethylene glycol methyl ether-polylactide block copolymer and sodium silicate into the system according to the dosage required by the formula, stir evenly, and heat and stir if necessary.

[0026] (4) When the temperature is below 30-45°C, add oily spices, vitamin E, and vitamin C according to the dosage required by the formula, and make up the remaining water.

Embodiment 1

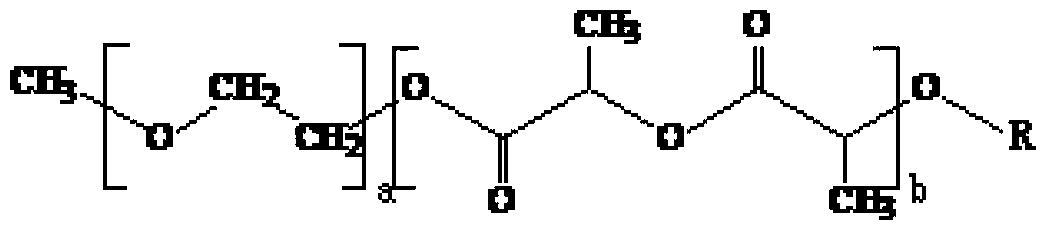

[0028] (1) Preparation of polyethylene glycol methyl ether-polylactide block copolymer

[0029] 2 g of polyethylene glycol monomethyl ether (MPEG) with a molecular weight of 2000 and 3 g of D,L-lactide (also known as lactic acid), 0.15 mL of stannous octoate / tetrahydrofuran solution (0.1 g / mL) were added to the well-dried polymer In the bottle, vacuum-dry at 80°C for 5 hours, then melt seal the polymerization bottle, polymerize at 130°C for 15 hours, break the polymerization bottle, dissolve the polymer in dichloromethane, precipitate with ether, repeat the above dissolution and precipitation steps three times to obtain polyethylene glycol methyl ether -Polylactide (MPEG-PLA for short) (molecular weight 1800-18000).

[0030] (2) Preparation of phenylalanine-based polyethylene glycol methyl ether-polylactide block copolymer

[0031] Take 2g MPEG-PLA, 0.25g L-phenylalanine, 0.08g condensing agent N,N′-dicyclohexylcarbodiimide DCC, dissolve in 30mL DMF, adjust the pH value to 9....

Embodiment 2

[0040] (1) The preparation method of the ecological laundry liquid in which the alanine-based polyethylene glycol methyl ether-polylactide block copolymer is used as a surfactant is the same as in Example 1.

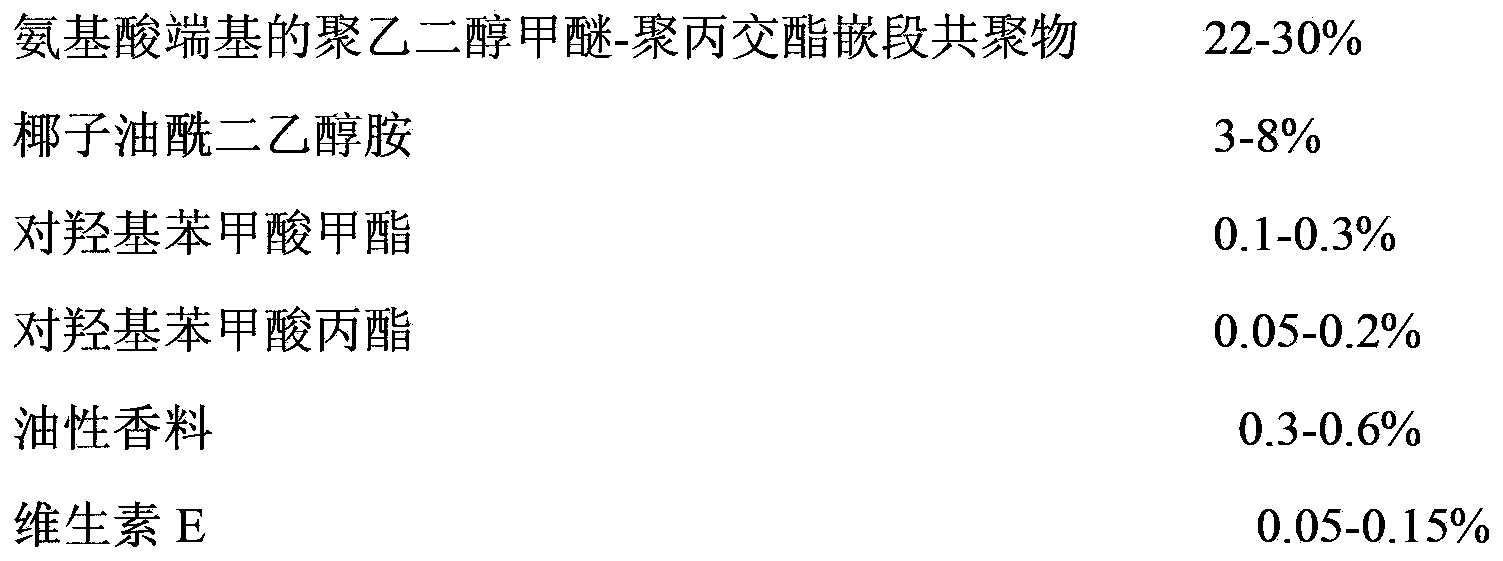

[0041] The ecological laundry detergent prepared by the present embodiment, by weight percentage, laundry detergent is made up of following components:

[0042]

[0043] The rest is water, and its total weight satisfies 100%. (2) Performance testing

[0044] ① Detergency: According to the detergency test method in GB / T13174-2008, compared with the national standard washing powder (the standard washing powder dosage is 0.2%, the washing liquid dosage is 0.3%), the detergency of carbon black is 1.13, and the sebum removal Pollution power 1.03.

[0045] ②Foam performance: According to GB / T13173.6-2000 Detergent Foam Strength Test Method, measured by Roche foam, the instant foam is 97mm, and the 5min foam is 28mm.

[0046] ③Cytotoxicity test: To test the cytotoxicity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com