A kind of porous hydroxyapatite bioceramic and preparation method thereof

A technology of hydroxyapatite and water-based hydroxyapatite is applied in the field of porous hydroxyapatite bioceramic and its preparation to achieve the effect of large compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

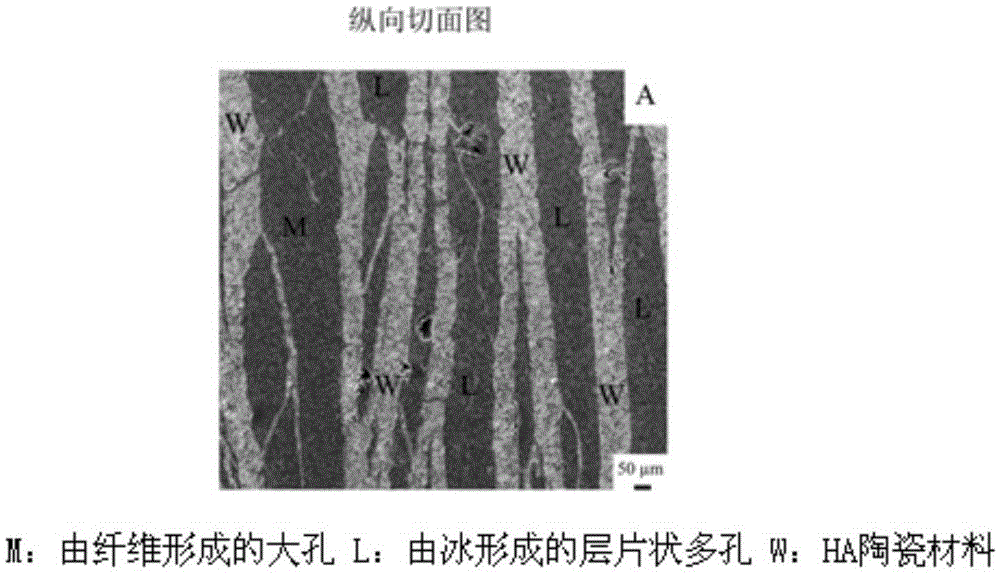

Method used

Image

Examples

Embodiment 1

[0024] 1) Add 100 g of deionized water, 1 g of polyacrylamide, 1 g of polyvinyl alcohol, and 5 g of hydroxyapatite powder into the ball mill tank, and after ball milling for 20 hours, water-based hydroxyapatite slurry is obtained;

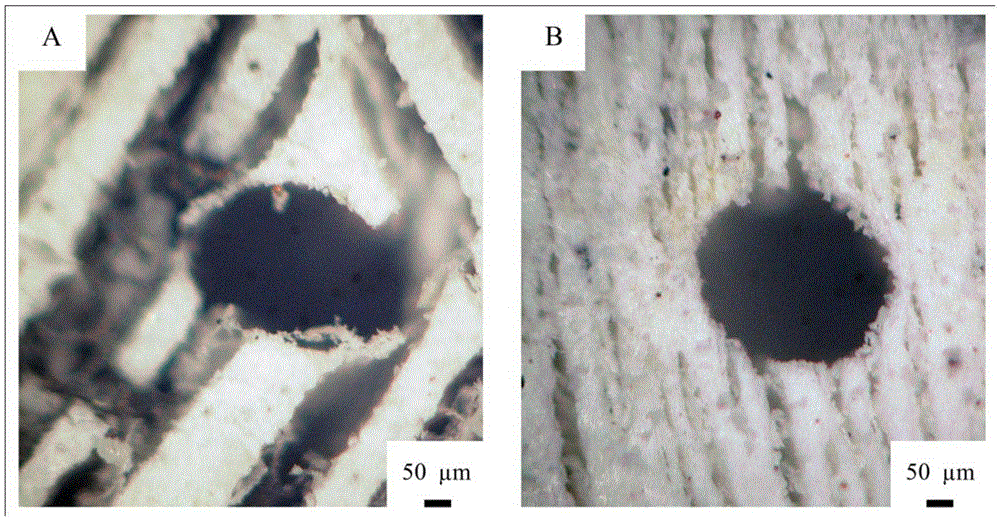

[0025] 2) Fix the two ends of the mold with a polyester braided net with a diameter of 185 μm, and then use a polyester thread with a diameter of 165 μm to pass through the mesh holes at both ends, so that they are oriented in the mold;

[0026] 3) After injecting the water-based hydroxyapatite slurry into the mold, put it into a container filled with liquid nitrogen for low-temperature directional solidification (that is, control the temperature and cooling rate at both ends of the mold by controlling the flow rate of liquid nitrogen at both ends of the mold, Realize the directional solidification of ice crystals, the same below), control the cooling rate to 5°C / min, and then freeze-dry the frozen green body in a freeze dryer;

[0027] 4) The drie...

Embodiment 2

[0029] 1) Add 95 g of deionized water, 0.5 g of polyacrylamide, 0.5 g of polyvinyl alcohol, and 35 g of hydroxyapatite powder into the ball mill tank, and after ball milling and mixing for 30 hours, water-based hydroxyapatite slurry is obtained;

[0030] 2) Fix nylon braided nets with a diameter of 530 μm at both ends of the mold, and then use nylon wires with a diameter of 510 μm to pass through the mesh holes at both ends, so that they are oriented in the mold;

[0031] 3) After injecting the water-based hydroxyapatite slurry into the mold, put it into a container filled with liquid nitrogen for low-temperature directional solidification, control the cooling rate to 3°C / min, and then freeze-dry the frozen green body in a freeze dryer ;

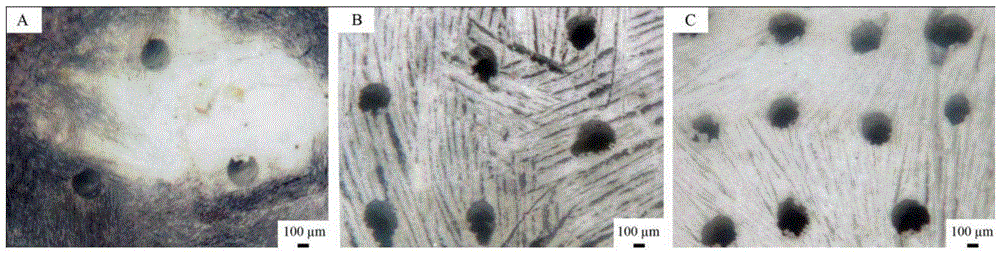

[0032] 4) The dried body was sintered at 1300°C, and after sintering for 1 hour, it was cooled to room temperature with the furnace temperature to obtain a porous hydroxyapatite ceramic with a pore diameter of 500 μm and a lamellar oriented ...

Embodiment 3

[0034] 1) Add 105g of deionized water, 2g of polyacrylamide, 2g of polyvinyl alcohol, and 150g of hydroxyapatite powder into the ball mill tank, and after ball milling and mixing for 20 hours, water-based hydroxyapatite slurry is obtained;

[0035] 2) Fix the two ends of the mold with a polyester braided net with a diameter of 1060 μm, and then use a polyester thread with a diameter of 1050 μm to pass through the mesh holes at both ends, so that they are oriented in the mold;

[0036] 3) After injecting the water-based hydroxyapatite slurry into the mold, put it into a container filled with liquid nitrogen for low-temperature directional solidification, control the cooling rate to 0.5°C / min, and then freeze-dry the frozen green body in a freeze dryer ;

[0037] 4) The dried green body was sintered at 1250°C, and after sintering for 1.5 hours, it was cooled to room temperature with the furnace temperature to obtain a porous hydroxyapatite ceramic with a pore diameter of 1000 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com