Preparation method of 4-bromoanisole

A technology for bromoanisole and anisole, which is applied in the field of preparation of 4-bromoanisole, can solve the problems of many wastes and high comprehensive cost, and achieves the effects of avoiding pollution, reducing production costs and having high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

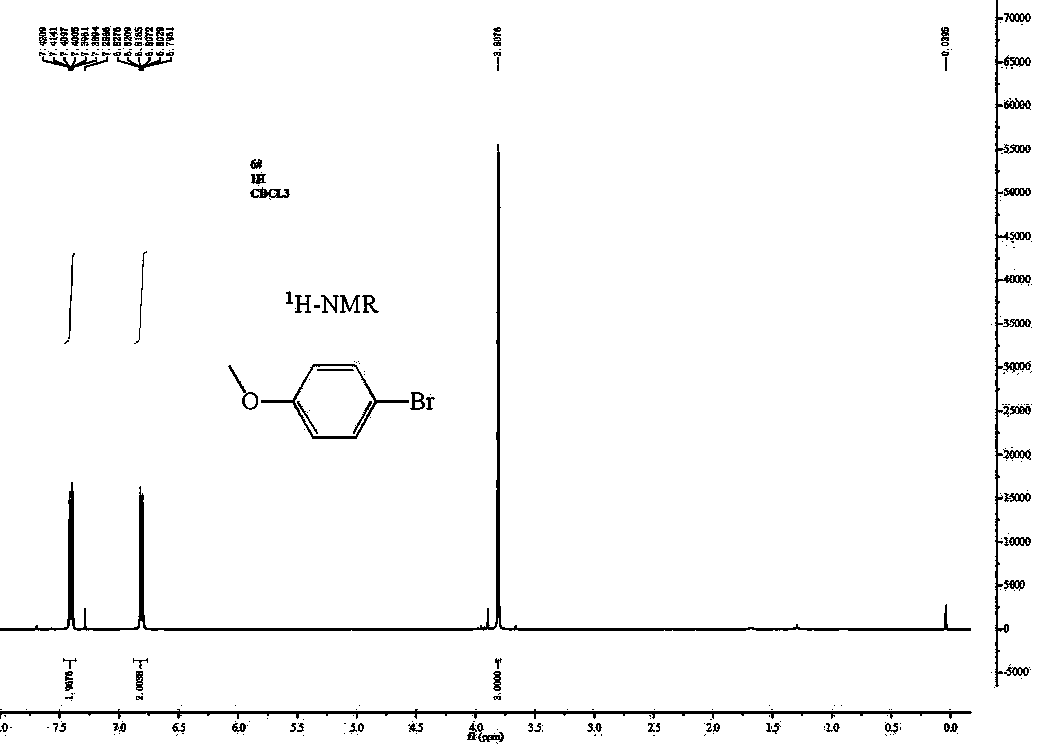

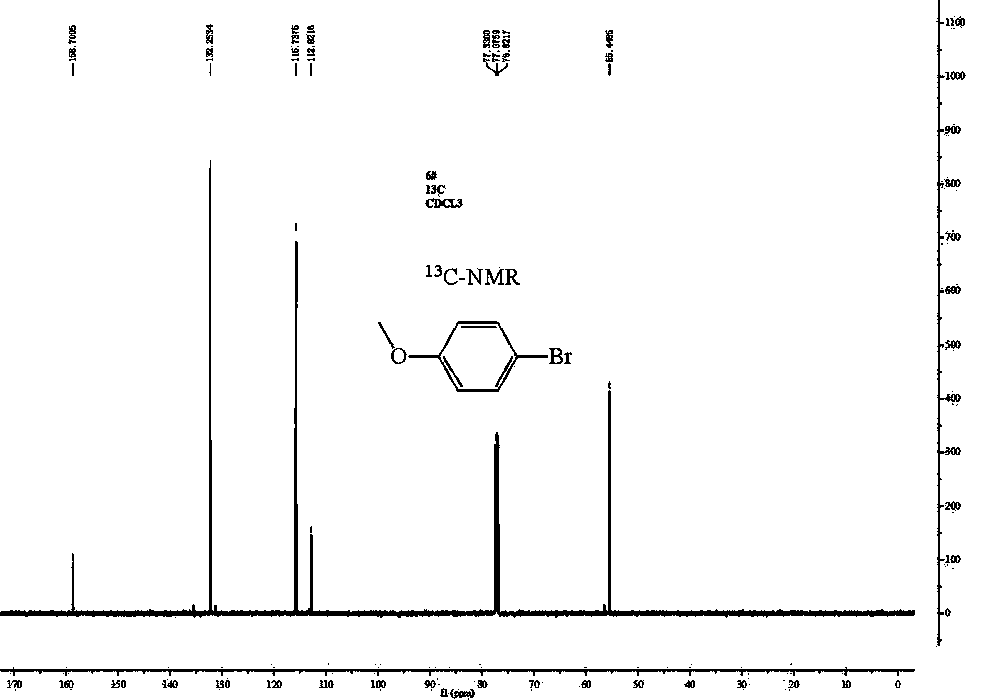

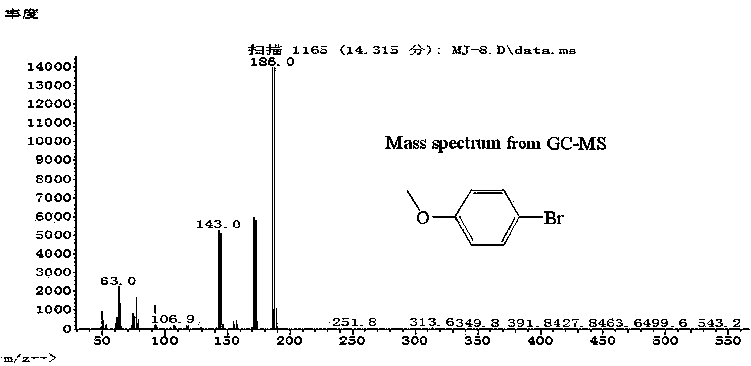

[0025] In the reaction tube, add magneton, 1ml of 1-butyl-3-methylimidazolium nitrate, 0.5mmol of anisole and 0.25mmol of Br 2 (without removing the air from the reaction tube). Then seal the reaction tube at 80 o C under magnetic stirring for 24h. After the reaction was completed, the reaction system was cooled to room temperature, 3 ml of distilled water was added, and the product was extracted with dichloromethane (3×10 mL). The combined organic phases were quantitatively analyzed by gas chromatography, and the gas phase internal standard yield of the product was 86%. The product was separated and purified by column chromatography to obtain 4-bromoanisole product. use 1 H-NMR, 3 C-NMR and 1 The structure of the product was determined by mass spectrometry see Figure 1-3 .

Embodiment 2

[0027] The reaction atmosphere in Example 1 was replaced by oxygen at normal pressure, and other conditions remained unchanged, and the gas phase internal standard yield of the product was 87%.

Embodiment 3-7

[0029] The temperature of reaction in embodiment 1 is changed into 25 respectively o C. 40 o C. 60 o C. 80 o C. 100 o C, with other conditions unchanged, the GC internal standard yields of the products were 54%, 72%, 81%, 86%, and 91%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com