A preparation method of biomimetic artemisinin molecularly imprinted composite film

A technology of molecular imprinting and composite membrane, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of poor kinetic performance and slow kinetic rate, and achieve remarkable separation effect, multiple times of reuse, and selectivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) SiO 2 Preparation of nanoparticles

[0049] First, prepare solution A: put 8mL of ammonia water, 16mL of ethanol and 24mL of water in a flask, and stir magnetically (1100rpm). Then configure solution B: mix 5mL tetraethyl orthosilicate (TEOS) and 45mL ethanol evenly. Add solution B to A quickly, and try not to let solution B touch the bottle wall. After one minute the stirring speed was reduced to 500 rpm. Seal the mouth of the reaction flask with parafilm, and react at room temperature for 3 hours. Centrifuge three times with ethanol and dry in vacuum.

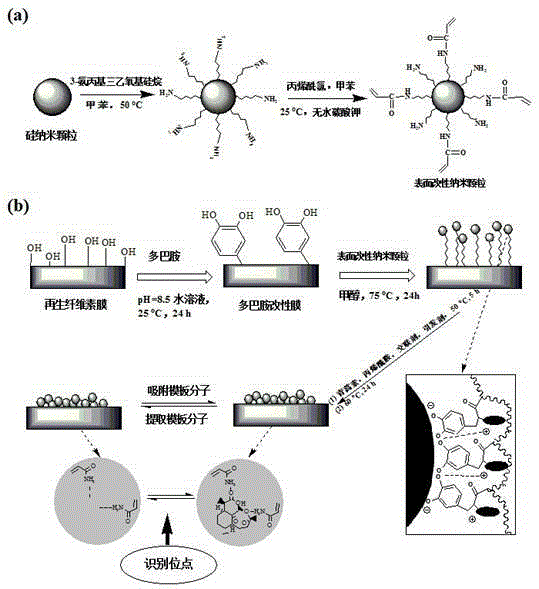

[0050] (2) Acrylamide surface modified SiO 2 Preparation of nanoparticles

[0051] First, 0.1 g of SiO obtained in (1) 2 Nanoparticles and 2mL 3-aminopropyltriethoxysilane (APTES) were mixed and dispersed in 50mL anhydrous toluene, under nitrogen protection for 50 o C was reacted for 12 hours. After the reaction, the resulting SiO 2 - APTES was centrifuged three times with toluene and dispersed in 50 mL o...

Embodiment 2

[0067] (1) SiO 2 Preparation of nanoparticles

[0068] First, prepare solution A: put 7mL of ammonia water, 14mL of ethanol and 21mL of water in a flask, and stir magnetically (1100rpm). Then configure solution B: mix 6mL tetraethyl orthosilicate (TEOS) with 54mL ethanol and mix well. Add solution B to A quickly, and try not to let solution B touch the bottle wall. After one minute the stirring speed was reduced to 500 rpm. Seal the mouth of the reaction flask with parafilm, and react at room temperature for 5 hours. Centrifuge three times with ethanol and dry in vacuum.

[0069] (2) Acrylamide surface modified SiO 2 Preparation of nanoparticles

[0070] First, 0.15 g of SiO obtained in (1) 2 Nanoparticles and 3mL 3-aminopropyltriethoxysilane (APTES) were mixed and dispersed in 50mL anhydrous toluene, under nitrogen protection for 50 o C was reacted for 12 hours. After the reaction, the resulting SiO 2 - APTES was centrifuged three times with toluene and dispersed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com