Organic/inorganic hybrid injection filling material and preparation method thereof

A kind of grouting filling material and inorganic technology, applied in the field of modified polymer materials, can solve the problems of expensive use, poor mechanical properties, low reaction heat release, etc., and achieve high foaming ratio, good flame retardancy, and low viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

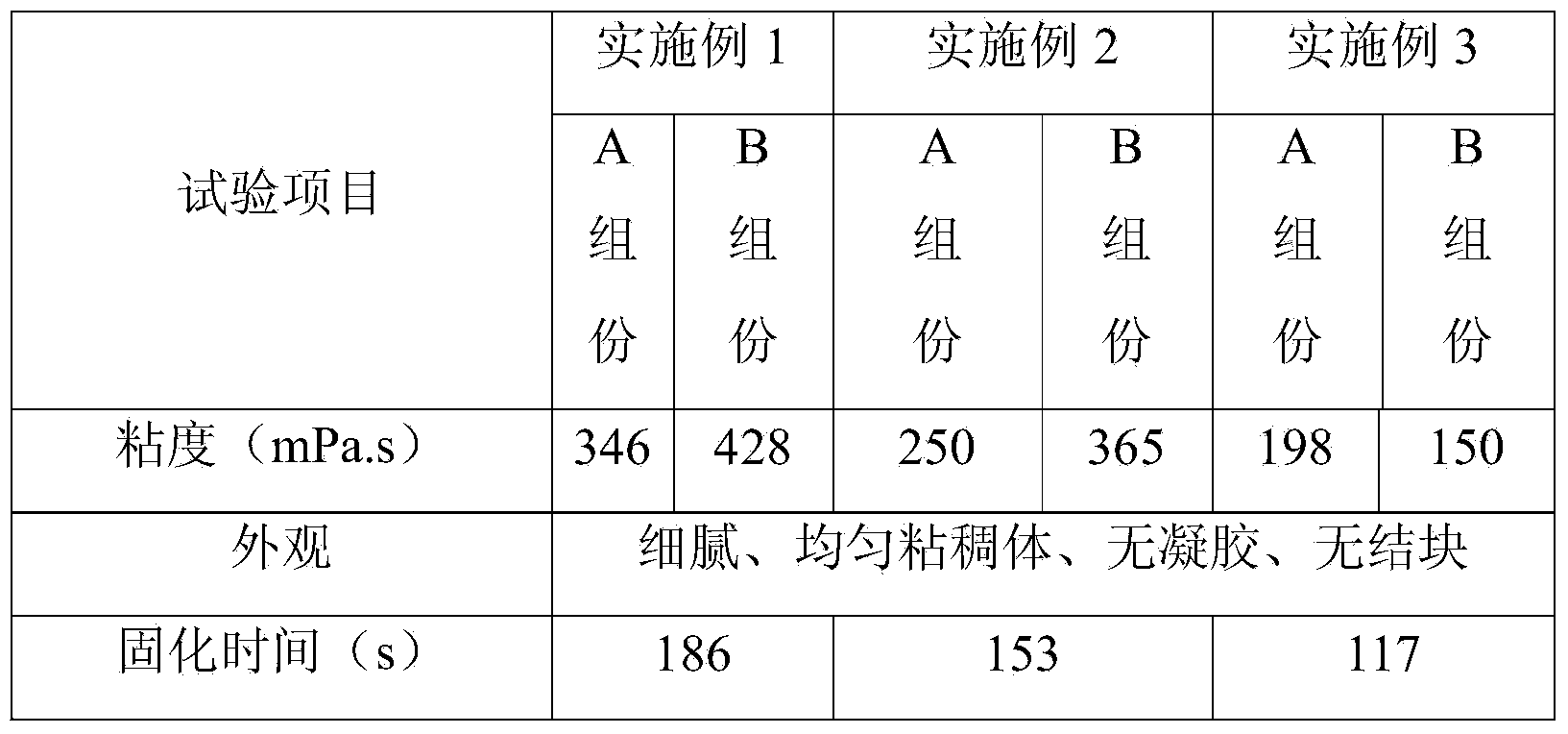

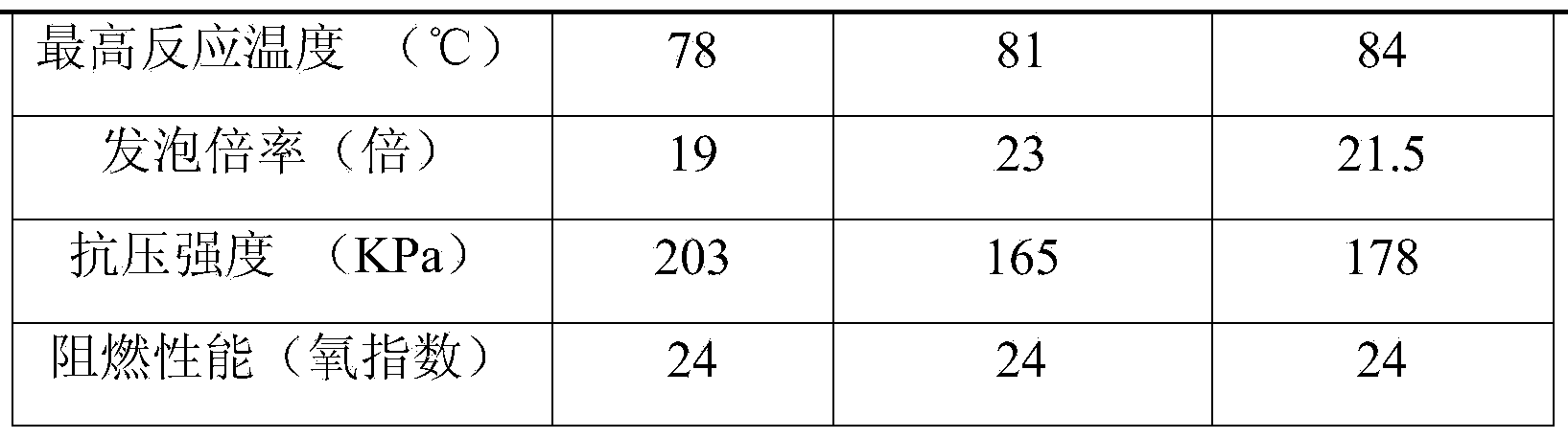

Embodiment 1

[0052] Example 1. Preparation of organic-inorganic hybrid grouting filling material

[0053]In the reaction kettle, first add 95wt% sodium silicate, start stirring at 25°C, slowly add 5wt% 2,4,6-tris[(dimethylamino)methyl]phenol dropwise, finish adding dropwise in 1 hour, and continue stirring After half an hour, the material was discharged and packaged to obtain component A.

[0054] In the interlayer reactor, first add 15wt% low unsaturation polyether polyol MN-700 (polypropylene oxide ether triol with a number average molecular weight of 700), at a temperature of 105 to 110°C (during the reaction The temperature fluctuates), and the vacuum degree is dehydration under the condition of -0.1MPa for 2.5 hours, cooling to 50°C, adding 70wt% polymethylene polyphenylisocyanate M20S and 2wt% 1,4-butanediol, and Keep the reaction for 30 minutes, heat up to 72°C, keep the temperature constant, react for 1 hour, cool down to 40°C, add 10wt% dibutyl phthalate and 3wt% additives (2.4wt...

Embodiment 2

[0056] Example 2. Preparation of organic-inorganic hybrid grouting filling material

[0057] In the reaction kettle, first add 93wt% potassium silicate, start stirring at 25°C, slowly add 7wt% pentamethyldiethylenetriamine dropwise, finish adding dropwise in 1 hour, continue stirring for half an hour, discharge the material, and pack to obtain the components a.

[0058] In the sandwich reactor, first add 25wt% polyether polyol DL-1000 (polypropylene oxide ether diol with a number average molecular weight of 1000), at a temperature of 105-110°C (the temperature fluctuates during the reaction process) ), the vacuum degree is -0.08Mpa, dehydration for 2.5 hours, cool down to 45°C, add 60wt% diphenylmethane diisocyanate, and keep the reaction for 20min, heat up to 80°C, keep the temperature constant, react for 2 hours, cool down to 50°C, add 13wt% diisononyl phthalate and 3wt% additives (2.5wt% AK-8803 foam stabilizer, 0.2wt% antioxidant 168 and 0.3wt% UV-P), stir well , dischar...

Embodiment 3

[0060] Example 3. Preparation of organic-inorganic hybrid grouting filling material

[0061] In the reaction kettle, first add 90wt% sodium silicate, start stirring at 25°C, slowly add 10wt% 1,3,5-tris(dimethylaminopropyl)hexahydrotriazine dropwise, and drop it in 1 hour. Continue to stir for half an hour, discharge, and pack to obtain component A.

[0062] In the interlayer reactor, first add 10wt% polyether polyol DL-400 (polypropylene oxide ether diol with a number average molecular weight of 400), at a temperature of 105-110°C (the temperature fluctuates during the reaction process) ), the vacuum degree is -0.09Mpa, dehydrated for 3 hours, cooled to 40°C, added 75wt% polymethylene polyphenylisocyanate PM-200 and 3wt% hexanediol, and kept the reaction for 30min, then raised the temperature to 70°C, Keep the temperature constant, react for 1.5 hours, cool down to 40°C, add 10wt% diethylene glycol butyl ether acetate and 2wt% additives (1.5wt% AK-8805 foam stabilizer and 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com