A kind of low particle precipitation medical polypropylene material and its preparation method and application

A polypropylene material and polypropylene technology, applied in the field of low particle precipitation medical polypropylene material and its preparation, can solve problems such as poor transparency, carcinogenicity, phlebitis, etc., and achieve improved toughness, good compatibility, and reduced particle precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

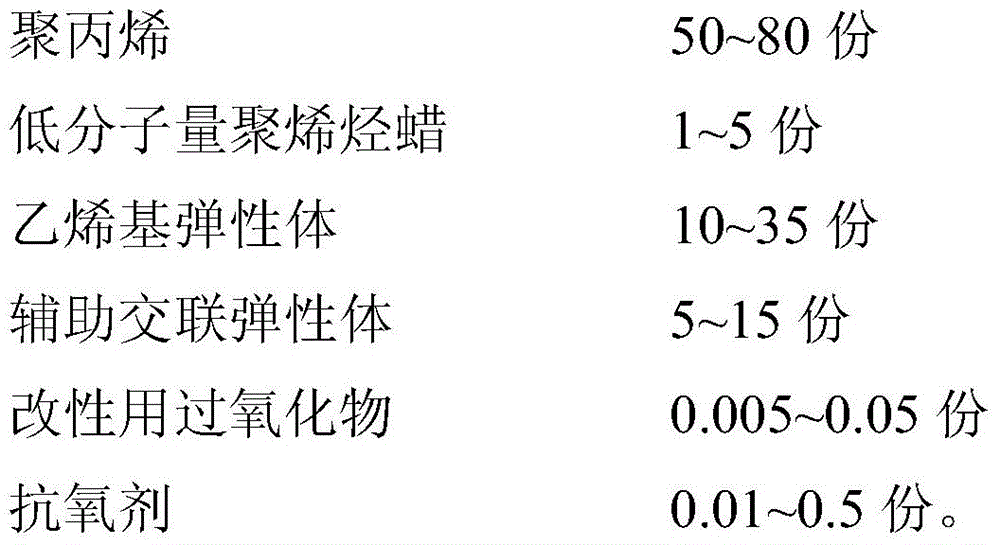

Method used

Image

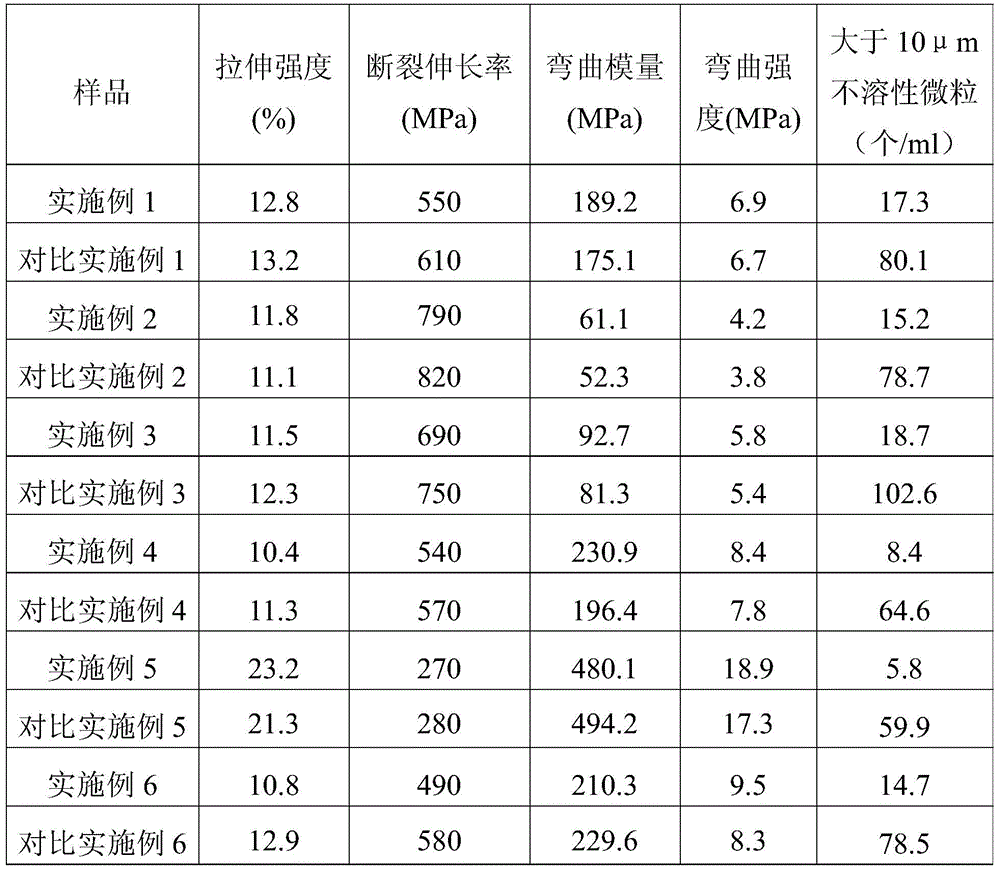

Examples

Embodiment 1

[0030] In terms of parts by mass, 60 parts of polypropylene (Dushanzi Tianli A180TM, 230 ° C, 2.16 kg load under the measured melt flow rate of 16.2 g / 10min), 25 parts of vinyl elastomer (Mitsui DF740, density 0.87 g / cm 3 ), 10 parts of auxiliary cross-linking elastomer (styrene-butadiene-styrene block copolymer, Li Changrong 1440, styrene content 40%), antioxidant (tetra[beta-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionic acid] pentaerythritol ester) 0.1 parts are mixed evenly, put into the extruder, melt kneading at the temperature of 150~200 ℃. After mixing and dispersing 0.02 parts of peroxide (dicumyl peroxide) for modification and 5 parts of low molecular weight polyolefin wax (LicowaxPE520, the average molecular weight is 2300), the feed from the middle section of the extruder screw is quantified by weight loss weighing. The feed port is added, continuous extrusion, water cooling, pelletizing, and the product is obtained.

Embodiment 2

[0032] In terms of parts by mass, 50 parts of polypropylene (Fu polyene STM866, 230 ° C, the melt flow rate measured under a load of 2.16kg is 8g / 10min), 30 parts of vinyl elastomer (DOW ENGAGETM 8180, density 0.86g / cm 3 ), 15 parts of auxiliary cross-linking elastomer (EPDM, Dow NORDEL 3430), antioxidant (Wingstay-L and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) Propionic acid] pentaerythritol ester compound, the mass ratio is 2:3) 0.02 parts are mixed evenly, added to the extruder, and melted and kneaded at a temperature of 150-200 °C. Mix and disperse 0.05 parts of peroxide (tert-butyl hydroperoxide) for modification and 5 parts of low-molecular-weight polyolefin wax (SCGLP1040P, average molecular weight 4200), and use a weight loss scale to quantify the feed from the middle section of the extruder screw. The feed port is added, continuous extrusion, water cooling, pelletizing, and the product is obtained.

Embodiment 3

[0034] In terms of parts by mass, 55 parts of polypropylene (Fu polyene STM866, 230 ° C, the melt flow rate measured under a load of 2.16kg is 8g / 10min), 10 parts of vinyl elastomer (DOW ENGAGETM 8150, density 0.868g / cm 3 ), 5 parts of auxiliary cross-linked elastomer (1,2-polybutadiene, JSR RB820, crystallinity: 25%), 0.01 part of antioxidant (tetra[β-(3,5-di-tert-butyl-4 -Hydroxyphenyl)propionic acid]pentaerythritol ester and tris[2.4-di-tert-butylphenyl]phosphite compound, the mass ratio is 2:3), mix evenly, add to the extruder, at 150~200℃ Melt kneading at temperature. After mixing and dispersing 0.005 parts of peroxide (lauroyl peroxide) for modification and 5 parts of low molecular weight polyolefin wax (PP6105A, average molecular weight of 9300) evenly, use a weight loss scale to quantify the amount from the feeding port of the middle section of the extruder screw. Adding, continuous extrusion, water cooling, pelletizing to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com