Completely biodegradable polyester material and preparation and application of completely biodegradable polyester

A technology for biodegrading polyester and caprolactone, which is applied in the field of polymer biodegradable materials, can solve problems such as unsatisfactory product performance, achieve controllable degradation speed, excellent mechanical properties, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

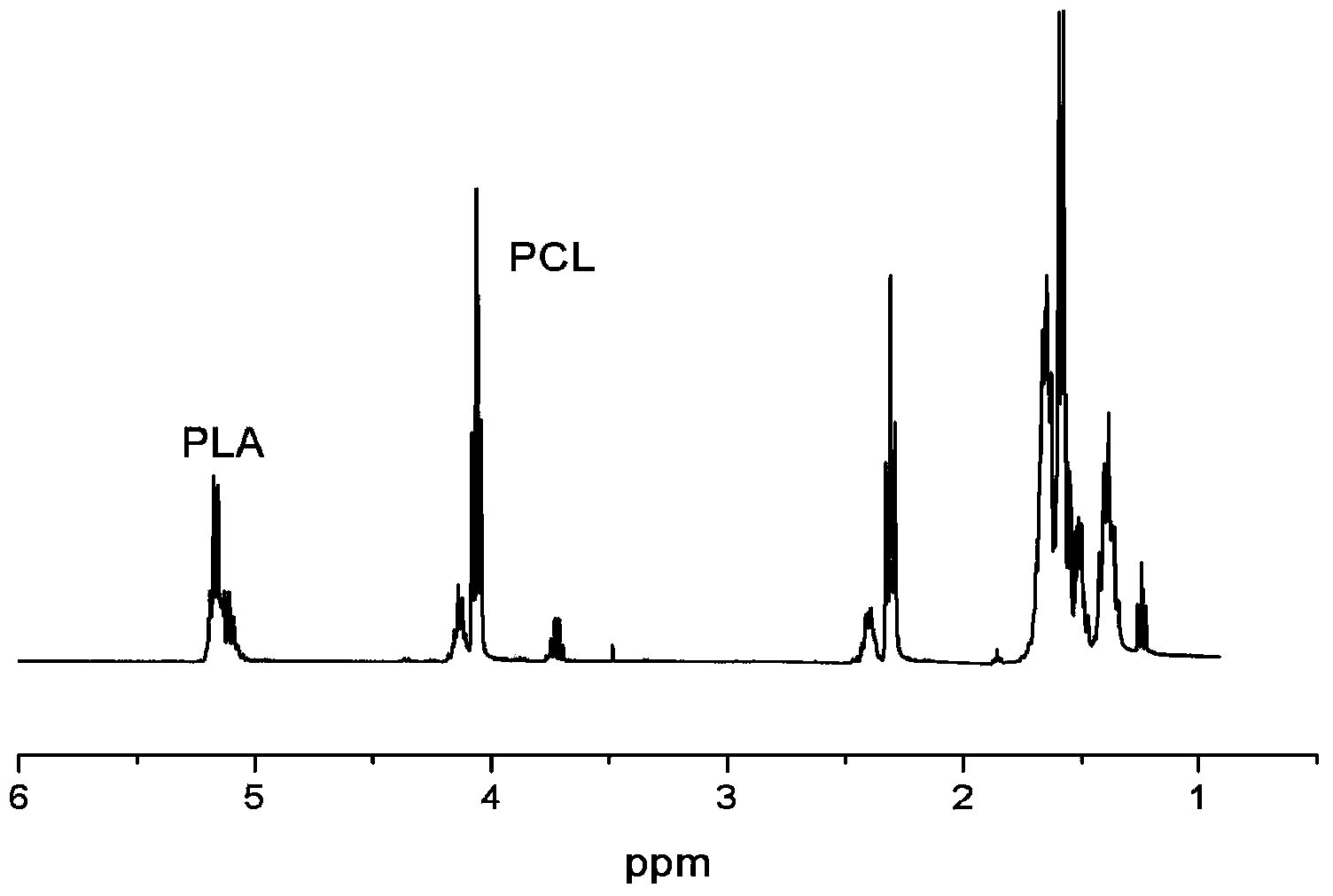

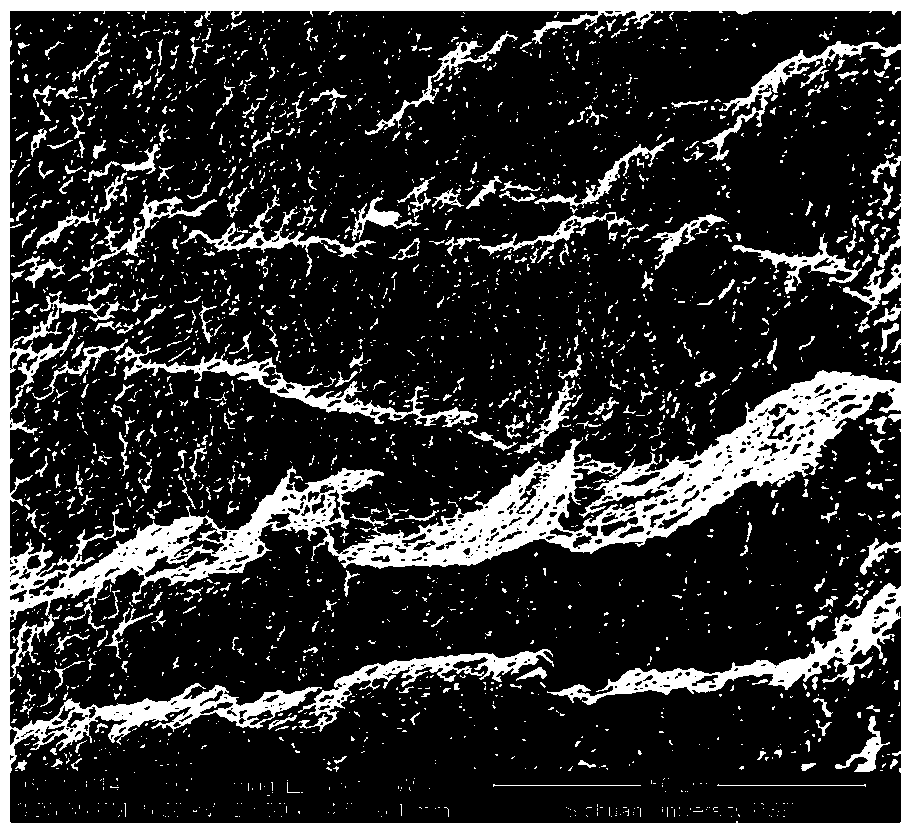

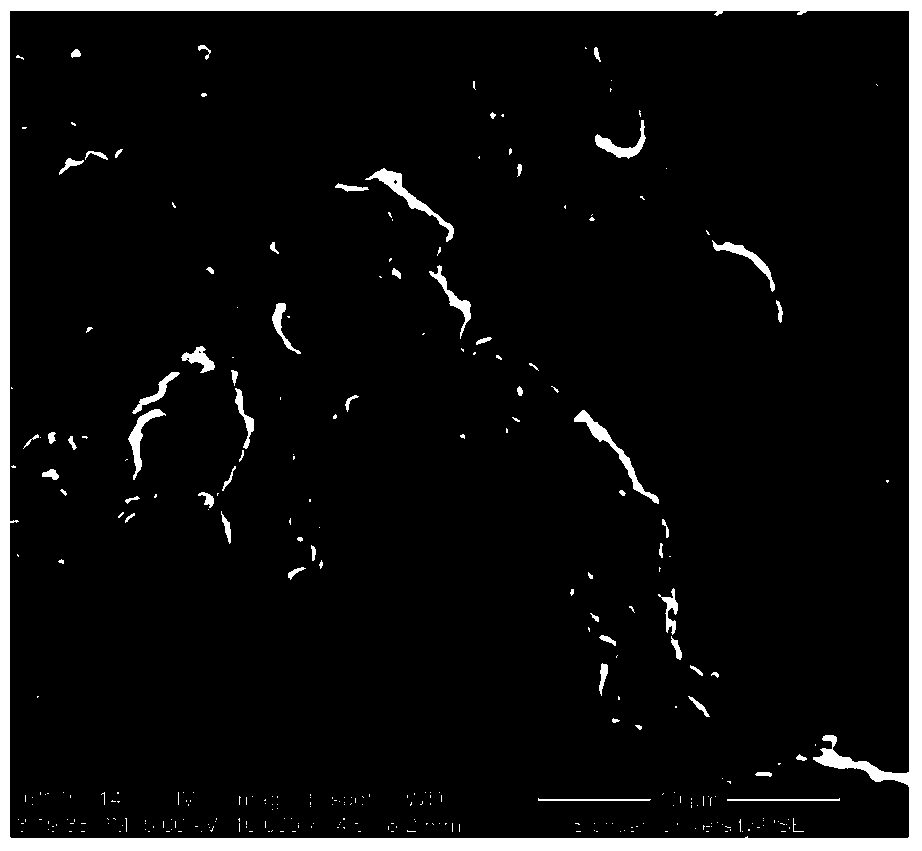

Method used

Image

Examples

Embodiment 1

[0028] Mix 0.05 parts of n-decyl alcohol initiator with 25 parts of purified cyclic lactone (the ratio of lactic acid monomer to caprolactone monomer is 90:10), vacuum dry, and then add 0.01 parts based on the mass of cyclic lactone % of catalyst mixed, filled with nitrogen to drive away oxygen, vacuumize, repeat three times, control the vacuum degree of 0.05mmHg, vacuum seal the tube and react at 130°C for 48 hours to obtain a degradable poly(L-lactic acid-caprolactone) copolymer . The resulting product was purified and the number average molecular weight was determined to be 8.1×10 4 g / mol.

[0029] Dissolve 6 parts / gram of poly-L-lactic acid in 20 mL of dichloromethane solvent, add 4 parts / gram of the above-prepared poly(L-lactic acid-caprolactone) copolymer, stir well to completely dissolve the polymer, and gradually Add dropwise to 100mL of 1:1 water / ethanol mixture to precipitate the blend, filter and dry to obtain a fully biodegradable polyester material with mechanic...

Embodiment 2

[0031] After drying 20 parts of poly(L-lactic acid-caprolactone) obtained in Example 1 and 180 parts of poly-L-lactic acid at 80°C for 5 hours, they were added to a twin-screw extruder, and the screw speed was controlled at 15 rpm , the extrusion temperature is 180°C, and the residence time of the material is 5 minutes, that is, a fully biodegradable polyester material with excellent mechanical properties is obtained.

Embodiment 3

[0033] Mix 0.1 part of tris(hydroxymethyl)ethane initiator with 50 parts of purified cyclic lactone (the ratio of lactic acid monomer to caprolactone monomer is 90:10), vacuum dry and follow the method described in Example 1 Synthesis of degradable poly(L-lactic acid-caprolactone) copolymers. The resulting product was purified and the number average molecular weight was determined to be 5.8×10 4 g / mol.

[0034] Dissolve 7.5 parts / gram of poly-L-lactic acid in 30 mL of dichloromethane solvent, add 2.5 parts / gram of poly(L-lactic acid-caprolactone) copolymer, stir well to dissolve the polymer completely, then gradually add to 200 mL The blend is precipitated in the water, filtered, and dried to obtain a fully biodegradable polyester material with excellent mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com