Method for improving yield of vernine from bacillus amyloliquefaciens

A technology of amylolytic spores and bacilli, applied in the field of bioengineering, to achieve stable production performance and high genetic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Construction of a guanosine-producing engineering bacterium B. amyloliquefaciens XH-△po based on Bacillus amyloliquefaciens XH7

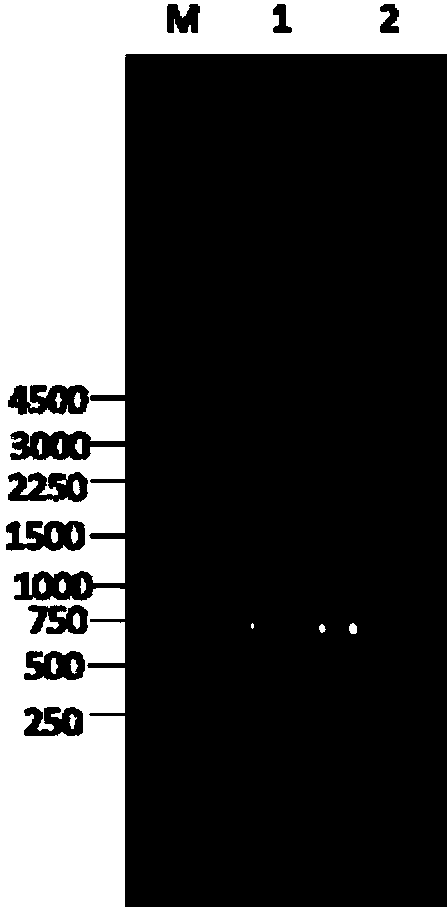

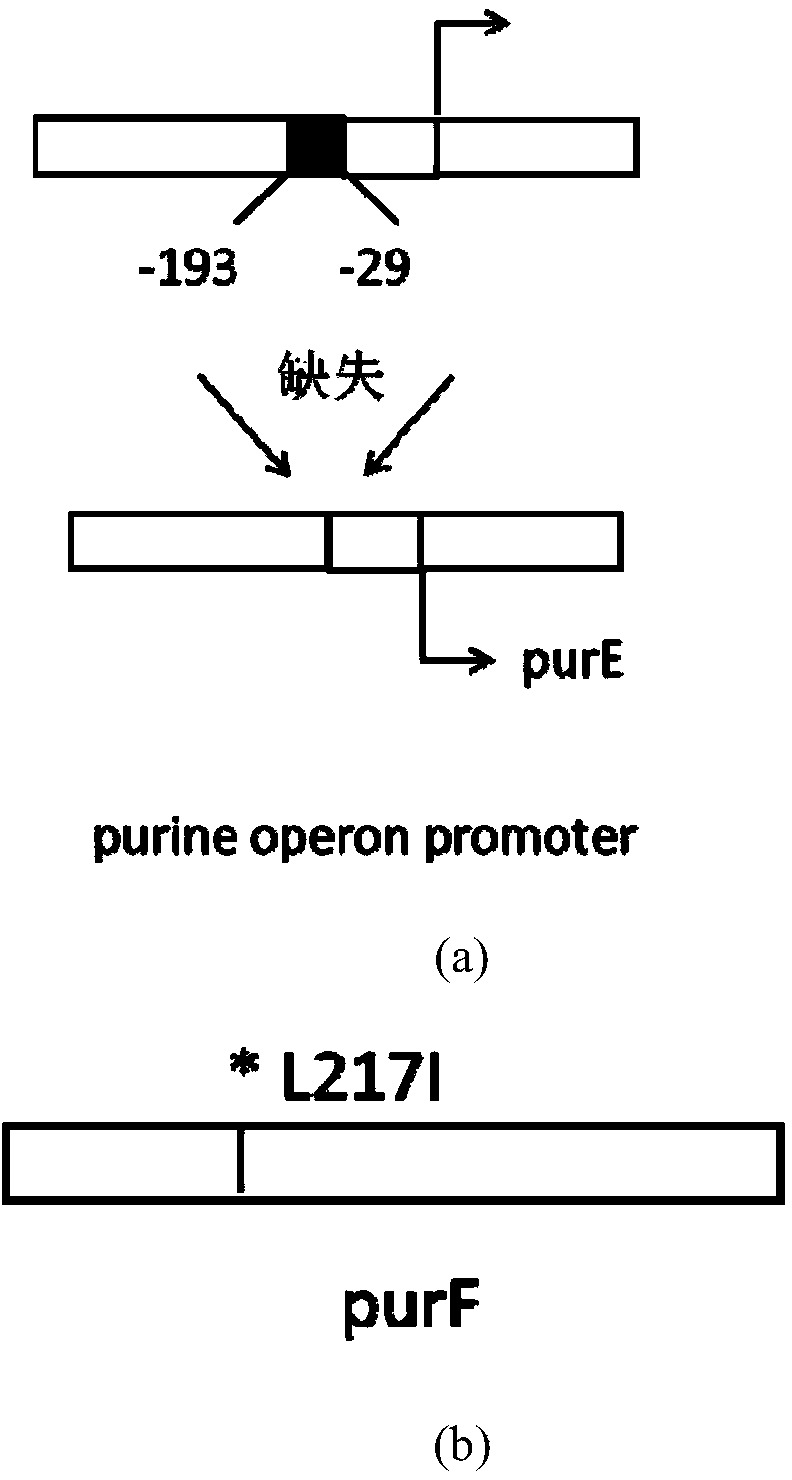

[0025] (1) Obtaining the truncated fragment containing the purine promoter: the DNA fragment containing the purine promoter gene of the Bacillus amyloliquefaciens DSM7 strain (Bacillus amyloliquefaciens XH7: CP002927) was obtained by PCR using the chromosomal DNA of the bacterium as a template, and the primer was SEQ ID No.3 and SEQ ID No.4 amplify the left arm of the homology arm, primers are SEQ ID No.5 and SEQ ID No.6 amplify the right arm of the homology arm, and the product of gene PCR amplification is recovered by gel, and then taken The amplified product with an equimolar ratio is used as a template, and the forward primer and reverse primer used are respectively SEQ ID No.3 and SEQ ID No.6, and the gene size truncated from -193 to -29 bp at the start codon of the purE gene is amplified Matching DNA fragments such as figure 1 As shown...

Embodiment 2

[0029] Construction of B. amyloliquefaciens XH7-△po-purF-217, a guanosine-producing engineered strain, based on Bacillus amyloliquefaciensXH-△po

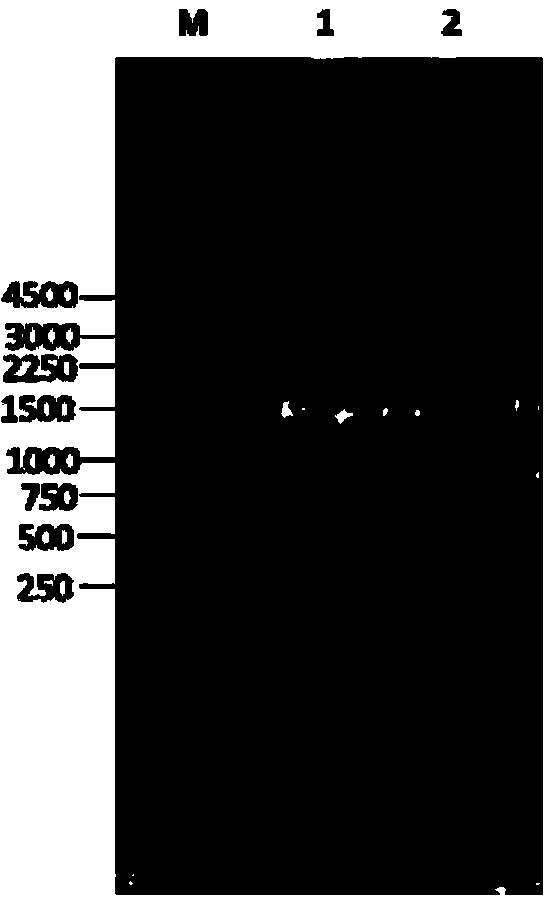

[0030] (1) PurF gene amplification and acquisition of mutant fragments: the DNA fragment containing the purine promoter gene of Bacillus amyloliquefaciens XH7 strain (Bacillus amyloliquefaciens XH7: CP002927) was obtained by PCR using the chromosomal DNA of the bacterium as a template, and the primers were SEQ ID No7, SEQ ID No8 amplify the left arm of the homologous arm, primers are SEQIDNo9, SEQIDNo10 amplify the right arm of the homologous arm, the product of gene PCR amplification is recovered from the gel, and then the amplified product in equimolar ratio is taken as a template. The forward primer and the reverse primer are respectively SEQ ID No.7 and SEQ ID No.10, and a DNA fragment of the same size containing the L217I mutation site of the purF gene is amplified. like figure 2 As shown, lane 1 in the figure is a DNA marker...

Embodiment 3

[0034] Detection of guanosine-producing ability of Bacillus amyloliquefaciensXH-△po and B. amyloliquefaciensXH7-△po-purF-217 constructed by shake flask fermentation

[0035] (1) From the preserved glycerol tube (glycerol concentration 18%, -80 ℃ preservation) streaked on the preferred solid activation medium (weight percentage) (ingredients: 1% peptone, 1% sodium chloride, 0.5% yeast extract extract, 1% glucose, 1.5% agar, and the balance is water), cultivated at 37°C for 24 to 36 hours; pick a single colony grown on a solid plate, and inoculate it on a shaker flask seed medium (percentage by weight) (ingredients: Glucose 1.5%, peptone 1%, yeast extract 0.5%, NaCl 0.5%, pH 7.2), cultured at 37°C for 6-7h, inoculated into shake flask fermentation medium (weight percentage) with an inoculum size of 10% by volume (8% glucose, 0.6% magnesium sulfate, 0.8% yeast powder, 0.15% potassium dihydrogen sulfate; 1.0% ammonium sulfate, 0.15% potassium chloride, 1.6% monosodium glutamate, 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com