Microwave aging treatment method for cobalt-based rare earth permanent magnetic materials

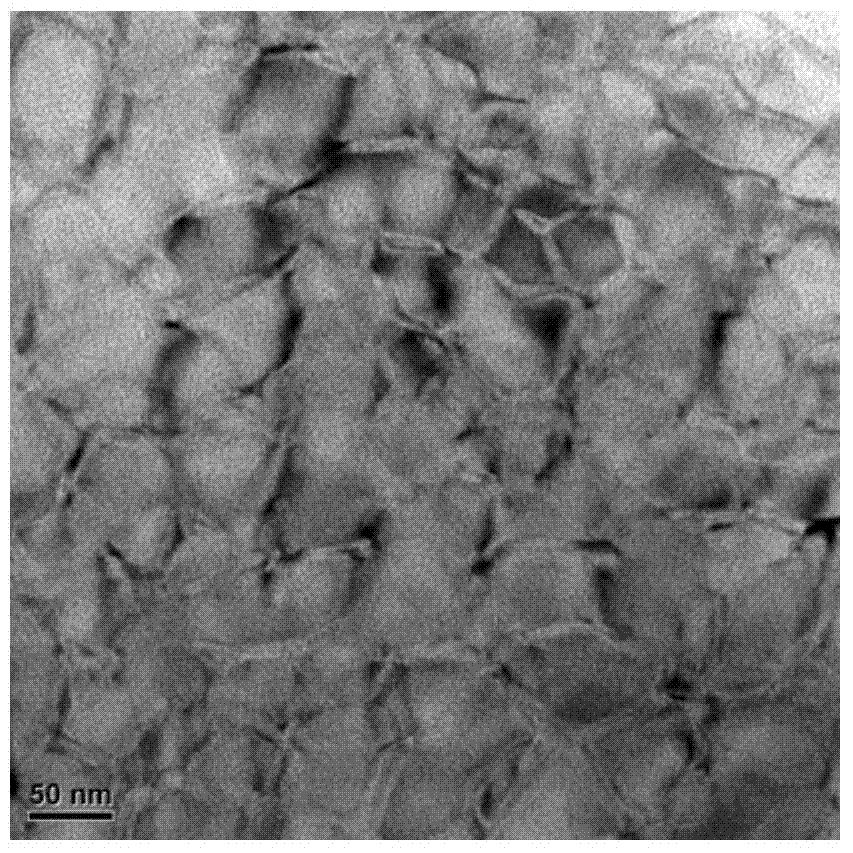

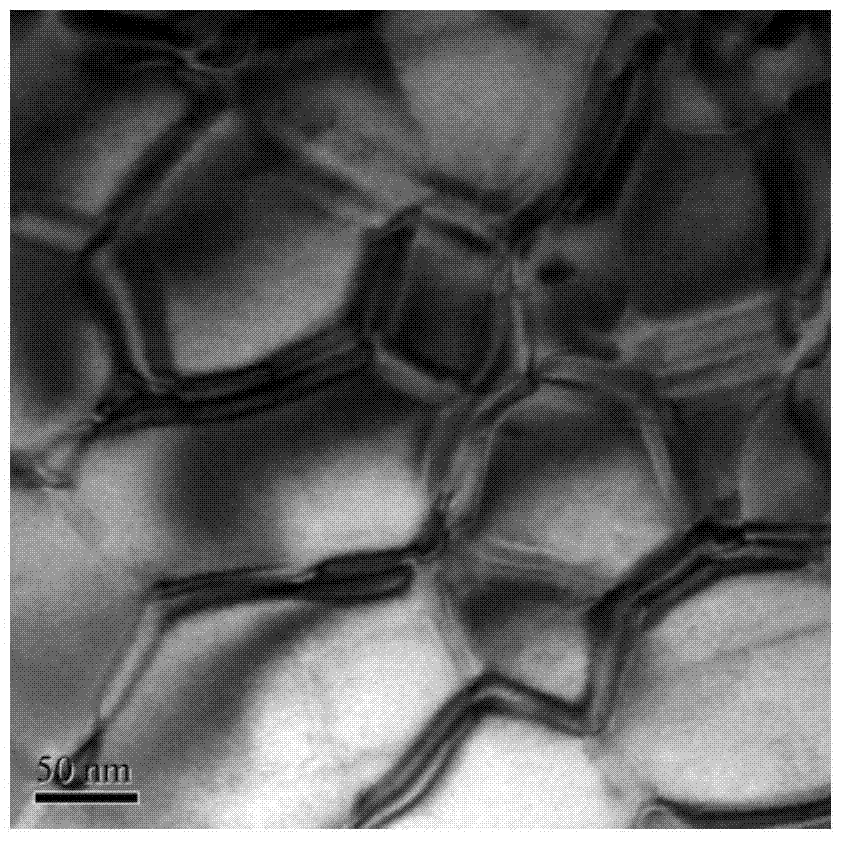

A rare earth permanent magnet and aging treatment technology, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of discontinuous cell wall phase, poor uniformity of cell structure, and destruction of cell structure, and achieve uniform cell structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

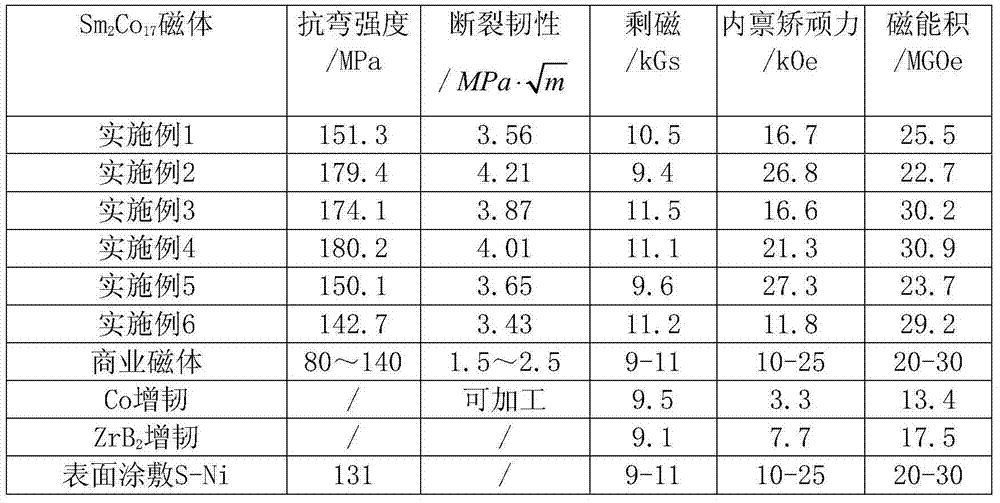

Examples

Embodiment 1

[0034] (1) Preparation of samarium cobalt rare earth permanent magnet material sintered billet: put the raw materials weighed in advance according to the stoichiometric ratio into an intermediate frequency induction furnace for smelting, wherein the mass fraction of Sm is 24.0%, Fe is 18.0%, and Co is 52.5% %, Zr is 1.5%, and Cu is 4%. The smelted alloy ingot is roughly crushed and ball-milled into alloy powder with an average particle size of 3-5 μm. The powder is oriented in a magnetic field of 1.5T, and is formed by means of vertical magnetic field steel molding. The formed blanks were pressed by isostatic pressing at a pressure of 300 MPa. The compact was pre-sintered in vacuum at 1190°C for 30min, then high-purity argon was introduced and the temperature was raised to the sintering temperature of 1225°C and kept for 2h. The sintered samples were solution-treated at 1190 °C for 2 h and then air-cooled.

[0035] (2) Put the solution-treated sample into the heat insulatin...

Embodiment 2

[0039] (1) Preparation of samarium cobalt rare earth permanent magnet material sintered billet: put the raw materials weighed in advance according to the stoichiometric ratio into the intermediate frequency induction furnace for smelting, wherein the mass fraction of Sm is 26.0%, Fe is 8.0%, and Co is 50.5% %, Zr is 3.5%, and Cu is 12.0%. The smelted alloy ingot is roughly crushed and ball-milled into alloy powder with an average particle size of 3-5 μm. The powder is oriented in a magnetic field of 1.5T, and is formed by means of vertical magnetic field steel molding. The formed blanks were pressed by isostatic pressing at a pressure of 200 MPa. The compacts were pre-sintered in vacuum at 1180°C for 30min, and then passed in high-purity argon and heated to a sintering temperature of 1201°C and kept for 2h. The sintered samples were solution-treated at 1180 °C for 2 h and then air-cooled.

[0040] (2) Put the solution-treated sample into the heat insulating body in the micr...

Embodiment 3

[0044] (1) Preparation of samarium cobalt rare earth permanent magnet material sintered blank: put the raw materials weighed in advance according to the stoichiometric ratio into the intermediate frequency induction furnace for smelting, wherein the mass fraction of Sm is 25.5%, Fe is 16.0%, and Co is 48.2% %, Zr is 2.3%, and Cu is 8.0%. The smelted alloy ingot is roughly crushed and ball-milled into alloy powder with an average particle size of 3-5 μm. The powder is oriented in a magnetic field of 1.5T, and is formed by means of vertical magnetic field steel molding. The formed blanks were pressed isostatically at a pressure of 250 MPa. The compact was pre-sintered in vacuum at 1190°C for 30min, and then high-purity argon was introduced and heated to a sintering temperature of 1215°C and kept for 2h. The sintered samples were solution-treated at 1190 °C for 2 h and then air-cooled.

[0045] (2) Put the solution-treated sample into the heat insulating body in the microwave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com