Method for preparing alpha-nickel sulfide and carbon nanometer rodlike composite material in in-situ mode

A nano-rod-like, composite material technology, applied in nanotechnology, hybrid/electric double-layer capacitor manufacturing and other directions, can solve the problems of large volume change, rapid capacitor capacity decay, etc., to achieve simple preparation process, controllable morphology, product Shape controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Disperse 0.3 g of dimethylglyoxime in 30 ml of absolute ethanol, and adjust the pH value of the dimethylglyoxime solution to 13.0 with 0.5 mol / L sodium hydroxide ethanol solution. Dissolve 0.3g of nickel chloride in 800mL of water, and add the dimethylglyoxime solution dropwise into the solution of nickel chloride under ultrasonic conditions to obtain a red flocculent substance. The above-mentioned red flocculent product was suction filtered, washed, and dried, and its scanning electron microscope photo was as follows: figure 1 As shown in (a); the above powder was calcined at 500 ° C for 1 h under Ar atmosphere to obtain a black powder, that is, nanorod-shaped carbon-coated nickel, and its scanning electron micrograph is as follows figure 1 (b) shown.

Embodiment 2

[0033] 5 milligrams of nano-rod-shaped carbon-coated nickel (prepared according to the method of Example 1) was added to 50 grams of glycerol solution for ultrasonic dispersion, then 75 milligrams of thiourea was added, stirred evenly and refluxed for 1 hour, naturally cooled to room temperature, and centrifuged , After washing, the α-nickel sulfide and carbon nanorod composite is obtained, and its scanning electron microscope and XRD pictures are as follows figure 2 (a) and (b) shown.

Embodiment 3

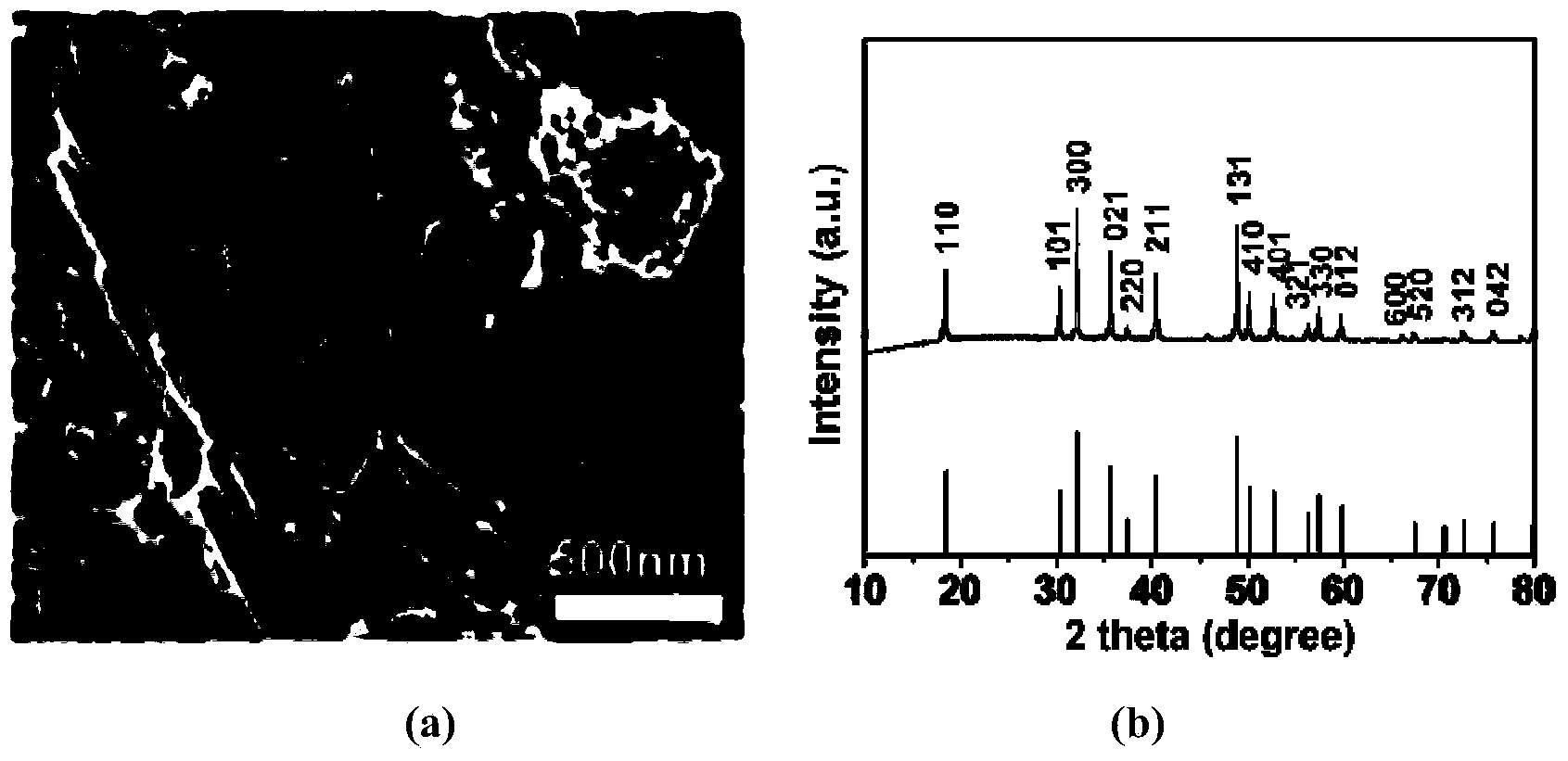

[0035] In the absence of nano-rod-shaped carbon-coated nickel, 2.5 mg of rod-shaped carbon and 2.5 mg of nano-nickel particles were added to 50 g of glycerol solution for ultrasonic dispersion, stirred evenly, refluxed in a two-necked flask for 0.8 hours, and cooled naturally to room temperature , after centrifugation and washing, agglomerated carbon nanorods and β-nickel sulfide particles were obtained. The scanning electron microscope and XRD pictures are as follows: image 3 Shown in (a) and (b), this result proves that nano-rod-shaped carbon-coated nickel of the present invention has a good nano-confinement effect on the crystal phase of the product in the reflow vulcanization process, thereby obtaining α-nickel sulfide with a single crystal phase and Carbon nanorod composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com