A kind of sic IGBT with low on-resistance and preparation method thereof

A low on-resistance, hole-blocking layer technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., to achieve the effects of enhanced conductance modulation, good turn-off loss, and good forward voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

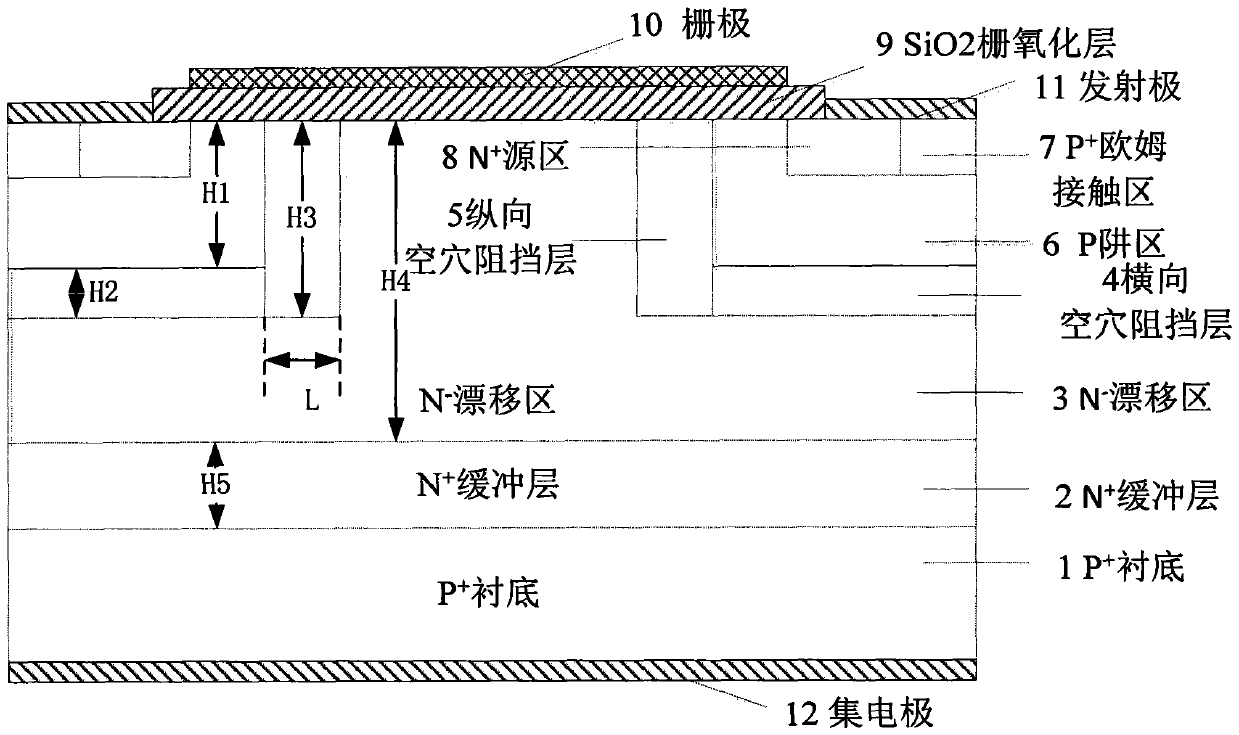

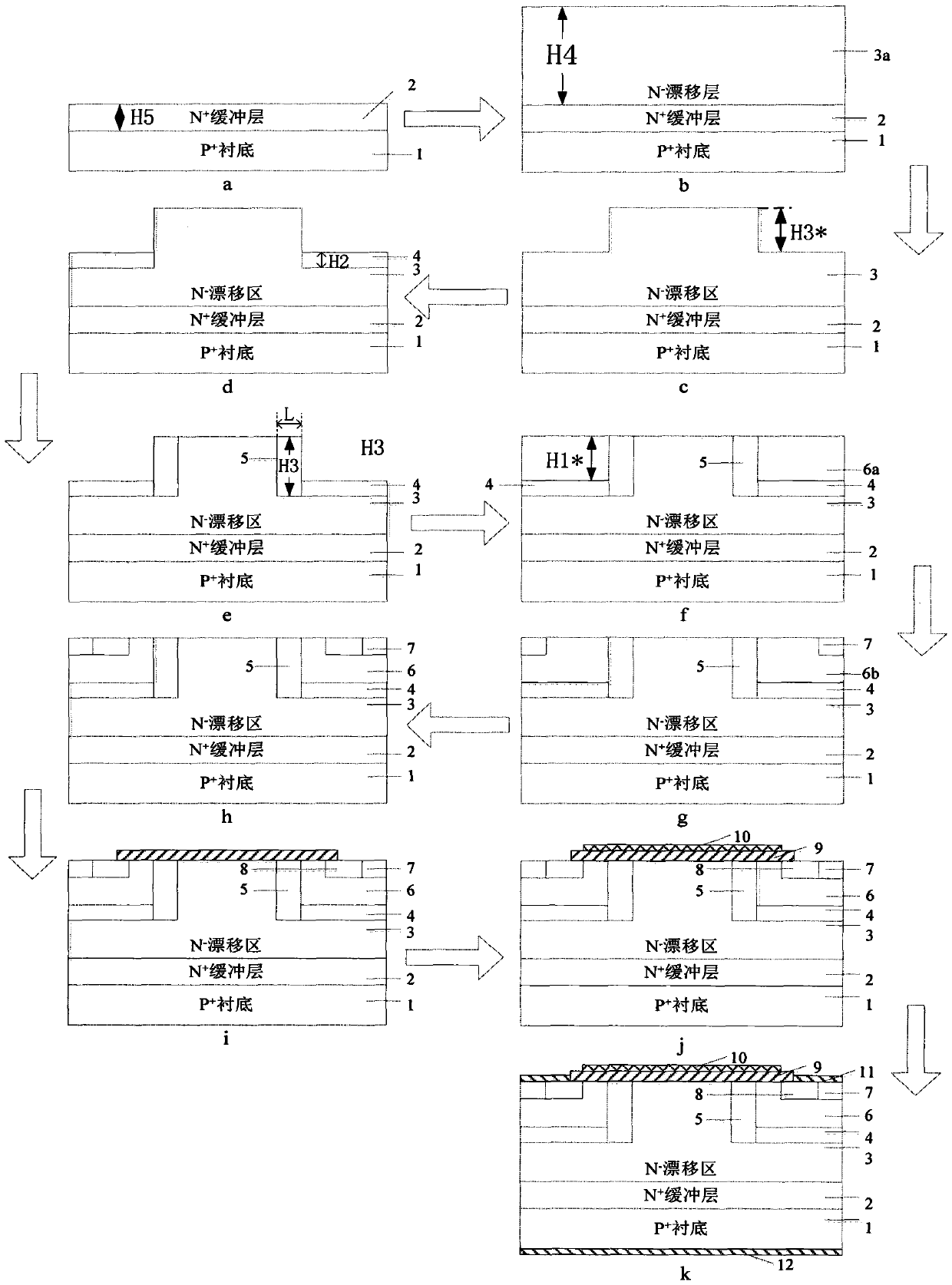

[0035] The embodiment of the present invention also provides a method for preparing the above-mentioned SiC IGBT, the method comprising the following steps:

[0036] S1, such as figure 2 As shown in the figure a, N + buffer layer (2), the doping concentration of the N+ buffer layer (2) is 8×10 16 -3×10 17 cm -3 , the thickness H5 is 2-14 μm.

[0037] By chemical vapor deposition, the P + Epitaxial growth on the substrate (1) forms N + For the buffer layer (2), the epitaxial growth temperature is 1600° C., the pressure is 100 mbar, the reaction gas is silane and propane, the carrier gas is hydrogen, and the impurity source is liquid nitrogen.

[0038] S2, such as figure 2 b as shown in the N + Formation of N on the buffer layer (2) - drift layer (3a), the N - The doping concentration of the drift layer (3a) is 2×10 14 cm -3 , the thickness H4 is 100-180 μm.

[0039] Using chemical vapor deposition method, in N + epitaxial growth on the buffer layer (2) to form N...

Embodiment 1

[0051] Step 1 at P + Epitaxial growth of N on the substrate + buffer layer, such as figure 2 a.

[0052] Using RCA cleaning standards for P + The SiC substrate sample was cleaned, and the epitaxial growth thickness on the entire substrate surface was 2 μm, and the nitrogen ion doping concentration was 8×10 16 cm -3 N + buffer layer, such as figure 2 a. The process conditions are as follows: the epitaxial growth temperature is 1650°C, the pressure is 100mbar, the reaction gas is silane and propane, the carrier gas is hydrogen, and the impurity source is liquid nitrogen.

[0053] Step 2 at N + Epitaxial growth of N on the buffer layer - drift layer, such as figure 2 b.

[0054] in N + Epitaxial growth of N on the buffer layer - Drift layer, nitrogen ion doping concentration is 2×10 14 cm -3 , with a thickness of 100 μm, such as figure 2 b. The epitaxy process conditions are as follows: the epitaxial growth temperature is 1650°C, the pressure is 100mbar, the re...

Embodiment 2

[0090] Step A in P + Epitaxial growth of N on SiC substrate samples + buffer layer, such as figure 2 a.

[0091] Using RCA cleaning standards for P + The SiC substrate sample was cleaned, and the epitaxial growth thickness on the entire substrate surface was 8 μm, and the nitrogen ion doping concentration was 1×10 17 cm -3 N + buffer layer, such as figure 2 a. The process conditions are as follows: the epitaxial growth temperature is 1650°C, the pressure is 100mbar, the reaction gas is silane and propane, the carrier gas is hydrogen, and the impurity source is liquid nitrogen.

[0092] Step B at N + Epitaxial growth of N on the buffer layer - drift layer, such as figure 2 b.

[0093] in N + Epitaxial growth of N on the buffer layer - Drift layer, nitrogen ion doping concentration is 2×10 14 cm -3 , with a thickness of 140 μm, such as figure 2 b. The epitaxy process conditions are as follows: the epitaxial growth temperature is 1650°C, the pressure is 100mbar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com