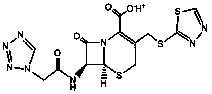

Process for preparing ceftezole sodium

A technology of ceftizole sodium and preparation process, applied in the direction of organic chemistry and the like, can solve the problems of complicated operation, high processing cost, small batch size and the like, and achieve the effects of simple solvent recovery, low processing cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 4.2L of N,N-dimethylacetamide and 10L of acetone to 1# dissolving tank, then add 3kg of ceftezole under stirring, then add 14L of acetone and 3L of purified water, stir until the solids are completely dissolved, Then add 0.1kg of medicinal activated carbon for decolorization for 30min, filter, and the filtrate is filtered through a 0.22 micron microporous membrane and then transferred to the aseptic workshop 1# metering drop tank through pipelines. Filtrate, then filter the filtrate through a 0.22 micron microporous membrane, combine the filtrates to obtain reaction solution A, and put it in 1# metering tank for use.

[0028] Add 10L of acetone to the 2# dissolving tank, add 1.47kg of sodium isooctanoate under stirring, stir until the solid is completely dissolved, then add 0.08kg of medicinal activated carbon for decolorization for 20 minutes, filter, and the filtrate is filtered through a 0.22 micron microporous membrane. Transfer the pipeline to the 1# crystalliz...

Embodiment 2

[0034] Add 2.8L of N,N-dimethylacetamide and 6.67L of acetone to 1# dissolving tank, then add 2kg of ceftezole while stirring, then add 9.33L of acetone and 2L of purified water, and stir until the solid is completely Then add 0.07kg of medicinal activated carbon for decolorization for 30min, filter, and the filtrate is filtered through a 0.22 micron microporous membrane and then transferred to the aseptic workshop 1# metering drop tank through pipelines. After filtering, rinse the 1# reactor with 2L acetone and filtered, then the filtrate was filtered through a 0.22 micron microporous membrane, and the filtrates were combined to obtain the reaction solution A, which was placed in a 1# metering tank for use.

[0035] Add 6.67L of acetone to 2# dissolving tank, add 0.98kg of sodium isooctanoate under stirring, stir until the solid is completely dissolved, then add 0.05kg of medicinal activated carbon for decolorization for 20 minutes, filter, and filter the filtrate through a 0....

Embodiment 3

[0042]Add 2.94L of N,N-dimethylacetamide and 10L of acetone to 1# dissolving tank, then add 3kg of ceftezole while stirring, then add 14L of acetone and 1.5L of purified water, and stir until the solids are completely dissolved , then add 0.1kg of imported medicinal activated carbon for decolorization for 30 minutes, filter, and the filtrate is filtered through a 0.22 micron microporous membrane and then transferred to the aseptic workshop 1# metering drop tank through pipelines. After filtering, rinse the 1# reactor with 3L acetone and filtered, then the filtrate was filtered through a 0.22 micron microporous membrane, and the filtrates were combined to obtain the reaction solution A, which was placed in a 1# metering tank for use.

[0043] Add 10L of acetone to the 2# dissolving tank, add 1.14kg of sodium isooctanoate under stirring, stir until the solid is completely dissolved, then add 0.08kg of imported medicinal activated carbon for decolorization for 20 minutes, filter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com