Preparation method of silicon dioxide graft graphene oxide/rubber composite material

A technology of silica and composite materials, applied in the field of aviation tire tread rubber, can solve the problems of high heat generation and poor wear resistance of aviation tires, and achieve the effects of improving service life, improving hardness and modulus, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of silica-grafted graphene oxide nanoparticles: use flake graphite as raw material, prepare graphite oxide by Hummers oxidation method, and form a uniformly dispersed graphene oxide mixed solution with a mass concentration of 0.5g / ml by 1000W ultrasonic treatment; Add 50g of sodium silicate and 200ml of deionized water into a 250ml Erlenmeyer flask, add 1.0ml of concentrated hydrochloric acid dropwise, and stir at 50°C for 24h. Pour the reaction solution into a 500ml beaker, add 100ml tetrahydrofuran, and add 30gNaCl, stir evenly, use a separatory funnel to separate the liquid, discard the lower clear liquid, and add 20g anhydrous MgSO to the upper organic liquid 4 Stand overnight, filter to obtain SiO 2 Sol; measure 15ml of ultrasonically dispersed graphene oxide mixed solution into the autoclave, add 30ml of SiO 2 Sol, put the reaction kettle in an oven at 80°C, react at a constant temperature for 2 hours, filter, wash, and dry to obtain gray-black powder...

Embodiment 2

[0024] The preparation method of silica-grafted graphene oxide nanoparticles is the same as in Example 1.

[0025] A silica-grafted graphene oxide / rubber composite material, the mass fraction of each component is: 100 parts of 1# smoked sheet rubber, 50 parts of super wear-resistant carbon black, 4 parts of white carbon black, 3 parts of silicon dioxide Grafted graphene oxide nanoparticles, 3.5 parts of silane coupling agent, 2 parts of heat stabilizer HS-80, 5 parts of zinc oxide, 3 parts of stearic acid, 2 parts of anti-aging agent 4020, 1 part of anti-aging agent RD, 2 parts of protection Wax, 2 parts of insoluble sulfur IS-60, 1 part of accelerator NOBS, 1 part of accelerator DZ, mixed evenly by internal mixer.

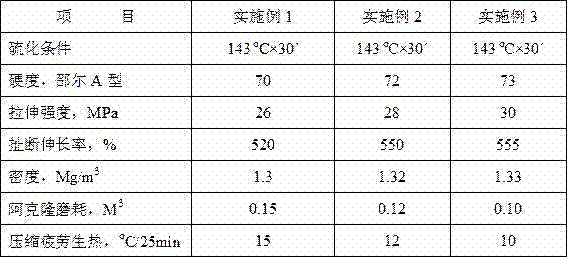

[0026] The silica-grafted graphene oxide / rubber composite was prepared, and its mechanical properties are shown in Table 1.

Embodiment 3

[0028] The preparation method of silica-grafted graphene oxide nanoparticles is the same as in Example 1.

[0029] A silica-grafted graphene oxide / rubber composite material, the mass fraction of each component is: 100 parts of 1# smoked sheet rubber, 50 parts of super wear-resistant carbon black, 4 parts of white carbon black, 4 parts of silicon dioxide Grafted graphene oxide nanoparticles, 5 parts of silane coupling agent, 2 parts of heat stabilizer HS-80, 6 parts of zinc oxide, 3 parts of stearic acid, 2 parts of anti-aging agent 4020, 1.5 parts of anti-aging agent RD, 2 parts of protection Wax, 2 parts of insoluble sulfur IS-60, 1 part of accelerator NOBS, 1 part of accelerator DZ, mixed evenly by internal mixer.

[0030] The silica-grafted graphene oxide / rubber composite was prepared, and its mechanical properties are shown in Table 1.

[0031] Table 1: Mechanical Properties of Compounds

[0032]

[0033] It can be seen from Table 1 that when a very small amount of si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com