Ultra-discharging water-soluble fluor-silicon-acrylic coatings with nano particles

A water-based fluorosilicone and nanoparticle technology, applied in coatings, latex paints, etc., can solve the problems of high prices and achieve low cost, stable properties, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Mix 15g deionized water, 10g silicon acrylic emulsion (solid content 35%), 7g polytetrafluoroethylene emulsion (solid content 55%), 3g nano silicon dioxide aqueous dispersion (diameter 5nm, solid content 15%) under stirring and 2g of ammonium bicarbonate, adjust the pH of the mixture to 8-10 with concentrated hydrochloric acid, and stir evenly to obtain a superhydrophobic water-based fluorosilicone-acrylic coating containing nanoparticles.

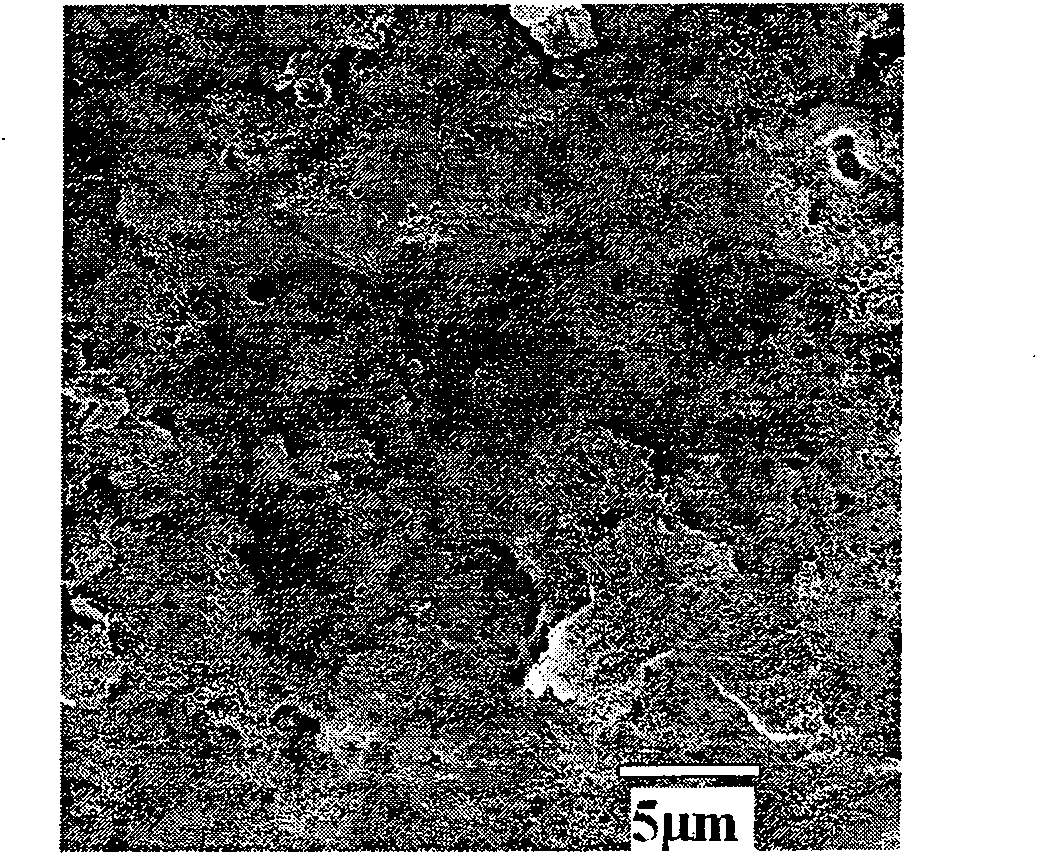

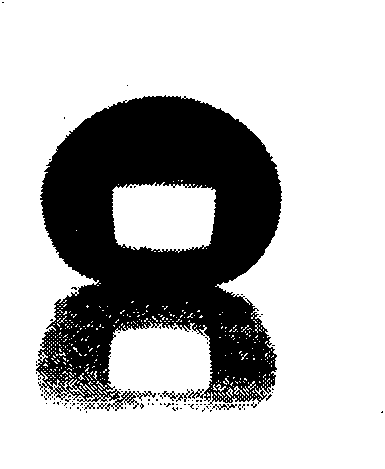

[0037] Thoroughly stir the coating prepared above, apply the coating evenly on the glass surface with a wet film preparation device with a thickness of 90 microns, and dry it at 80° C. for 15 minutes. The resulting white coating is a superhydrophobic water-based fluorosilicone coating (see figure 1 with figure 2 ). from figure 1 with figure 2 We can see that the surface of the superhydrophobic hydrofluorosilicone acrylic coating has a micro-nano binary structure, and there are particles of 120 to 130 nanometers on the nanometer...

Embodiment 2

[0040] Mix 15g deionized water, 15g silicon acrylic emulsion (solid content 35%), 9g tetrafluoroethylene and perfluorovinyl ether copolymer emulsion (solid content 50%), 1g nano-titanium dioxide (diameter 15nm) and 2g carbonic acid under stirring ammonium hydrogen, adjust the pH of the mixture to 8-10 with concentrated hydrochloric acid, and stir evenly to obtain a super-hydrophobic water-based fluorosilicone-acrylic coating containing nanoparticles.

[0041] Thoroughly stir the coating prepared above, apply the coating evenly on the surface of polyethylene terephthalate (PET) with a wet film preparation device with a thickness of 90 microns, and dry it at 50°C for 15 hours, and the obtained white coating is Superhydrophobic water-based fluorosilicone coating. The wettability of the coating surface was tested with a contact angle tester, and the result showed that the contact angle between the surface and water was 152±2°, and the rolling angle was 4±1°.

Embodiment 3

[0043] Mix 15g deionized water, 8g silicon acrylic emulsion (solid content 35%), copolymer emulsion (solid content 58%) of 12g tetrafluoroethylene and hexafluoropropylene, 4g nano silicon dioxide aqueous dispersion liquid (diameter 4nm) under stirring. , solid content 15%) and 3g of ammonium bicarbonate, adjust the pH value of the mixture to 7-9 with concentrated hydrochloric acid, and stir evenly to obtain a super-hydrophobic water-based fluorosilicone-acrylic coating containing nanoparticles.

[0044] Thoroughly stir the paint prepared above, apply the paint evenly on the surface of the stainless steel plate with a 90-micron thick wet film maker, and dry it at 80°C for 15 minutes. The white coating obtained is the superhydrophobic water-based fluorosilicone coating. The wettability of the coating surface was tested with a contact angle tester, and the result showed that the contact angle between the surface and water was 153±2°, and the rolling angle was 3±2°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com