A kind of thermophilic anaerobic bacterium and the method for using it to produce ethanol

A thermophilic anaerobic bacillus and ethanol technology, which is applied in the field of thermophilic anaerobic bacillus and its use in the production of ethanol, can solve the problems of increased production cost, long fermentation cycle, long growth lag period, etc., and achieve less by-products and process scale-up easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Acclimatization and isolation of strains

[0026] High sugar resistant thermophilic anaerobic bacteria strain of the present invention can be obtained like this:

[0027] In the present invention, the starting strain used for screening is Thermoanaerobacterium aotearoense SCUT27 / Δldh, which was screened, mutated and preserved in the laboratory, which is denoted as P8G0 here.

[0028] Screening medium: Glucose: 80-100g·L -1 ;Xylose: 40-60g·L -1 ; (NH 4 ) 2 SO 4 : 1-5g·L -1 ; MgCl 2 ·6H 2 O: 1-5g·L -1 ;KH 2 PO4 : 0.5-5g·L -1 ;K 2 HPO 4 : 0.5-5g·L -1 ; CaCl 2H 2 O: 0.1-2.0g·L -1 ;Na-β-glycerophosphate: 2-10g·L -1 ;FeSO 4 ·7H 2 O: 0.0001-0.001g·L -1 ;Yeast extract: 2-10g·L -1 ; Cysteine hydrochloride monohydrate (C 3 h 7 NO 2 S·HCl·H 2 O): 0.1-2.0g·L -1 ; Resazurin: 0.001-0.01g L -1 ;Agar powder: 5-20g·L -1 ; Erythromycin: 20-100ng / μl.

[0029] The starting strain P8G0 was first cultured in an anaerobic shake flask with 81g / L screening medium (...

Embodiment 2

[0034] Identification of P8G3#4 strains after domestication

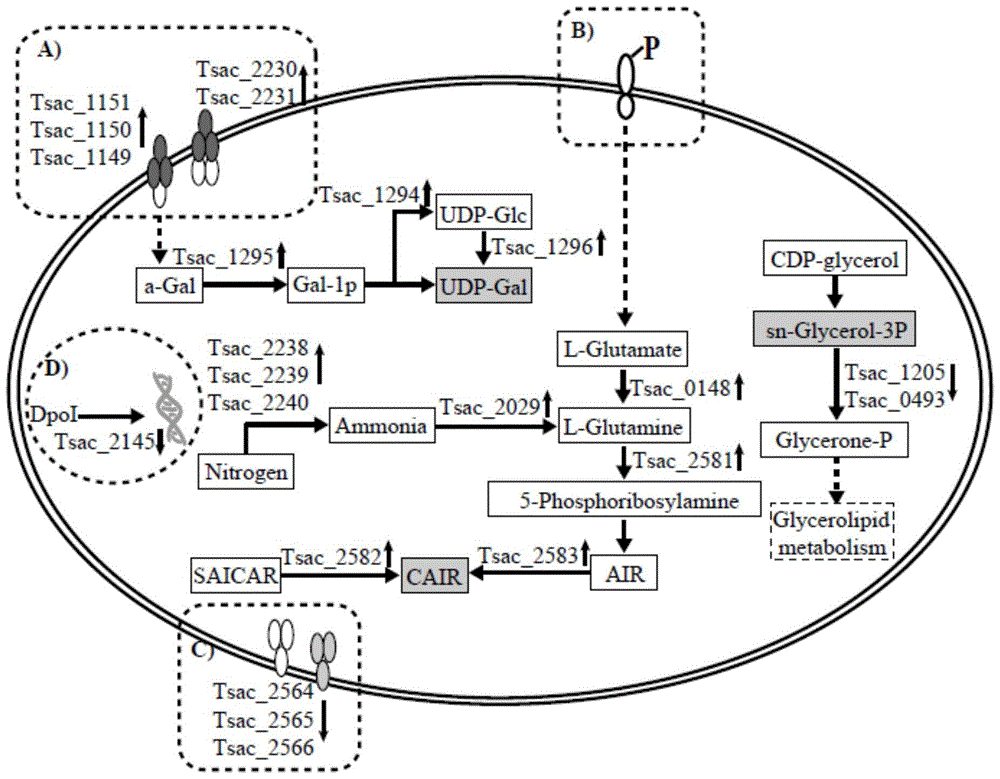

[0035] In order to identify the differences of the strains before and after domestication, transcriptomics method was used to analyze the differences of metabolic genes between P8G0 and P8G3#4, and cluster analysis was performed on the differential genes to identify the gene expression levels that lead to the differences in the growth and metabolism of the two strains of P8G0 and P8G3#4 s reason.

[0036] Transcriptome sequencing analysis was performed on the starting strain Thermoanaerobacterium aotearoense SCUT27 / Δldh P8G0 and the screened mutant strain P8G3#4 that can grow normally under high concentration of substrate. Analyze the differentially expressed genes in the two samples, the screening standard is |logFC|>=1 (ie two-fold difference), analyze the differentially expressed genes in the two samples, P8G0 and P8G3#4 have a total of 69 genes in the expression abundance There were significant differences. Com...

Embodiment 3

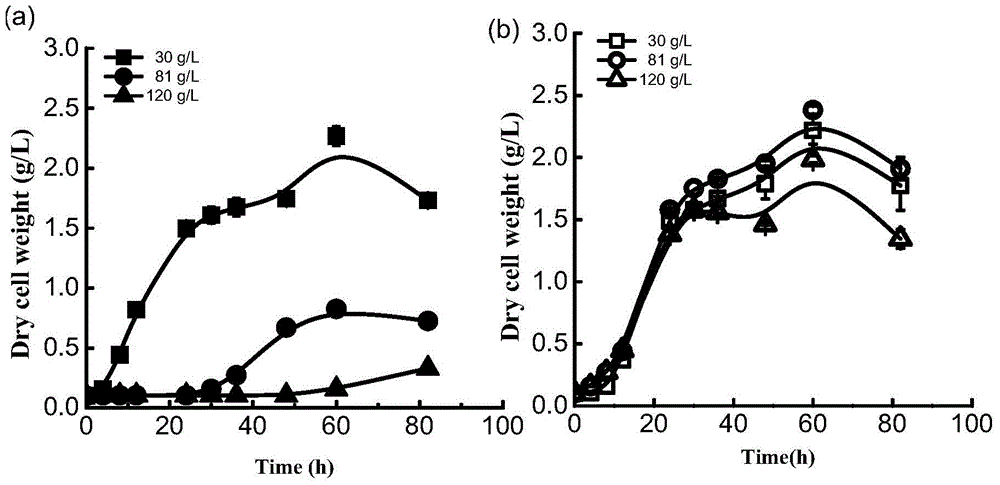

[0040] Shake flask fermentation culture to compare the growth difference between the domesticated high-sugar-tolerant strain and the original strain

[0041] Preparation of seed solution:

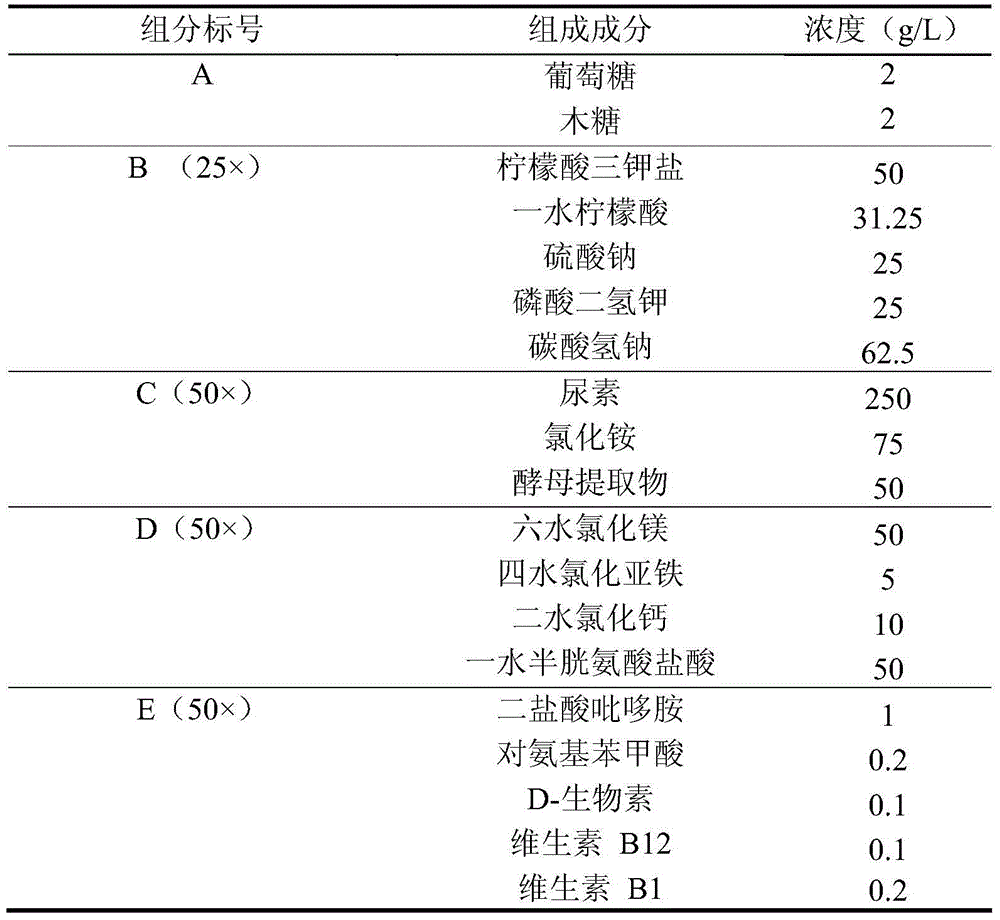

[0042] The seed medium adopts MTC improved medium, and various combinations of them can be divided into A, B, C, D, and E liquids, which are sterilized by high temperature respectively, and then mixed according to the ratio of 45:2:1:1:1 before use . The specific composition of each solution is shown in Table 1.

[0043]

[0044] Specifically, the preparation method of the seed culture medium is as follows: prepare liquids A, B, C, and D respectively and put them in serum bottles, vacuumize, fill with nitrogen, sterilize at 115°C for 20 minutes, and store them for later use; liquid E is sterilized by filtration and directly injected into Store in the serum bottle that has been filled with nitrogen and sterilized for later use; take the serum bottle that has been filled with liquid A, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com