Production method for preparing diammonium hydrogen phosphate and byproduct special fertilizer for oats

A technology of diammonium hydrogen phosphate and production method, applied in the directions of phosphate, phosphorus oxyacid, application, etc., can solve the problems affecting the purity of ammonium dihydrogen phosphate products, poor purity of ammonium dihydrogen phosphate products, and output of ammonium dihydrogen phosphate products low problems, achieve significant environmental protection value and economic benefits, reduce nitrogen and phosphorus elements, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

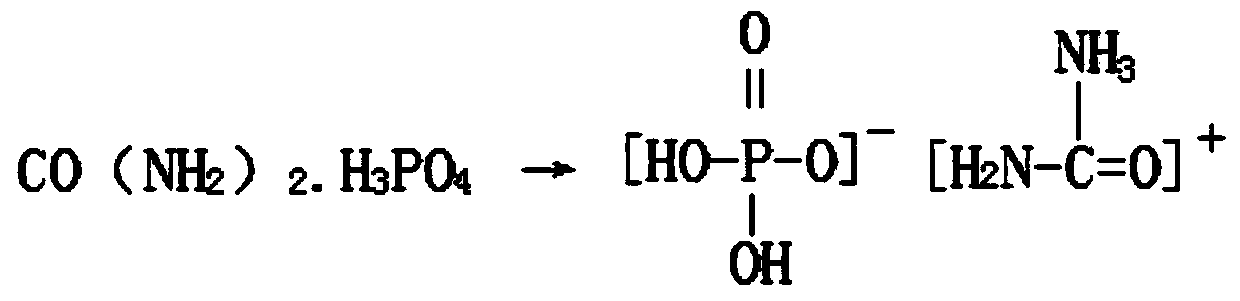

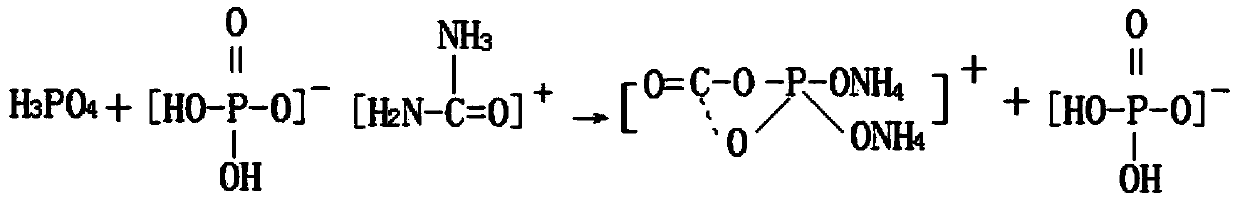

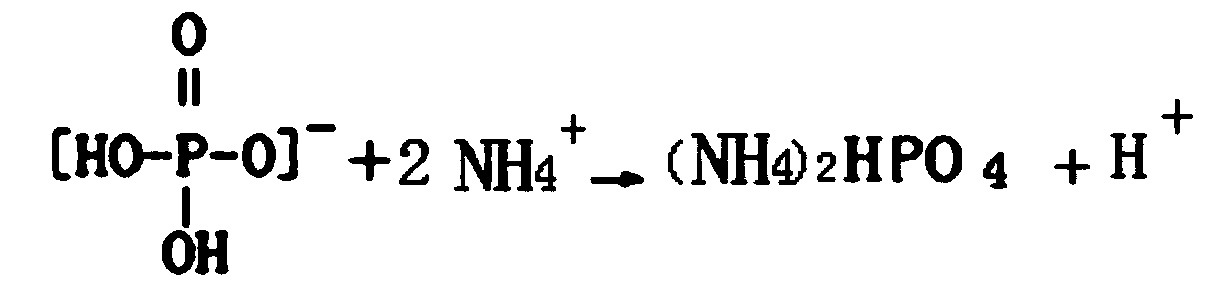

Method used

Image

Examples

Embodiment 1

[0047] A production method for preparing diammonium hydrogen phosphate by-product oat special fertilizer, comprising the following steps:

[0048] (1) Preparation and mixing of raw materials: Put phosphoric acid and urea in a stirred reactor at a molar ratio of 1.4:1, at a temperature of 80°C, and control the stirring speed of the stirred tank at 180r / min to stir and mix for 2 hours to obtain an intermediate material pulp;

[0049] (2) Preparation of diammonium hydrogen phosphate: pass ammonia gas into the intermediate slurry obtained in step 1), and control the temperature in the reactor to 50°C, adjust the pH value to 7.8, according to the stirring speed is 60r / min , stirred and reacted for 30min to obtain a slurry containing diammonium hydrogen phosphate product;

[0050] (3) Cyclic crystallization and filtration: place the slurry containing diammonium hydrogen phosphate obtained in step 2) in a cooling crystallizer to cool down to a temperature of 40°C within 15 seconds, ...

Embodiment 2

[0057] A production method for preparing diammonium hydrogen phosphate by-product oat special fertilizer, comprising the following steps:

[0058] (1) Preparation and mixing of raw materials: Put phosphoric acid and urea in a stirred reactor at a molar ratio of 1.9:1, at a temperature of 130°C, and control the stirring speed of the stirred tank at 200r / min to stir and mix for 3 hours to obtain an intermediate material pulp;

[0059] (2) Preparation of diammonium hydrogen phosphate: pass ammonia gas into the intermediate slurry obtained in step 1), and control the temperature in the reactor to 80°C, adjust the pH value to 8.2, and set the stirring speed to 80r / min , stirred and reacted for 50min to obtain a slurry containing diammonium hydrogen phosphate product;

[0060] (3) Cyclic crystallization and filtration: place the slurry containing diammonium hydrogen phosphate obtained in step 2) in a cooling crystallizer to cool down to a temperature of 30° C. within 15 seconds, co...

Embodiment 3

[0068] A production method for preparing diammonium hydrogen phosphate by-product oat special fertilizer, comprising the following steps:

[0069] (1) Preparation and mixing of raw materials: Put phosphoric acid and urea in a stirred reactor at a molar ratio of 1.65:1, at a temperature of 115°C, and control the stirring speed of the stirred tank at 190r / min to stir and mix for 2.5 hours to obtain an intermediate material pulp;

[0070] (2) Preparation of diammonium hydrogen phosphate: feed ammonia gas into the intermediate slurry obtained in step 1), and control the temperature in the reactor to 65°C, adjust the pH value to 8, and set the stirring speed to 70r / min , stirred and reacted for 40min to obtain a slurry containing diammonium hydrogen phosphate product;

[0071] (3) Cyclic crystallization and filtration: place the slurry containing diammonium hydrogen phosphate obtained in step 2) in a cooling crystallizer to cool down to a temperature of 35°C within 15 seconds, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com