Long-acting antibacterial amino molding compound

An amino molding compound and long-acting technology are applied in the field of long-acting bacteriostatic amino molding compounds to achieve the effects of good miscibility, stable structure, and improved bacteriostatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

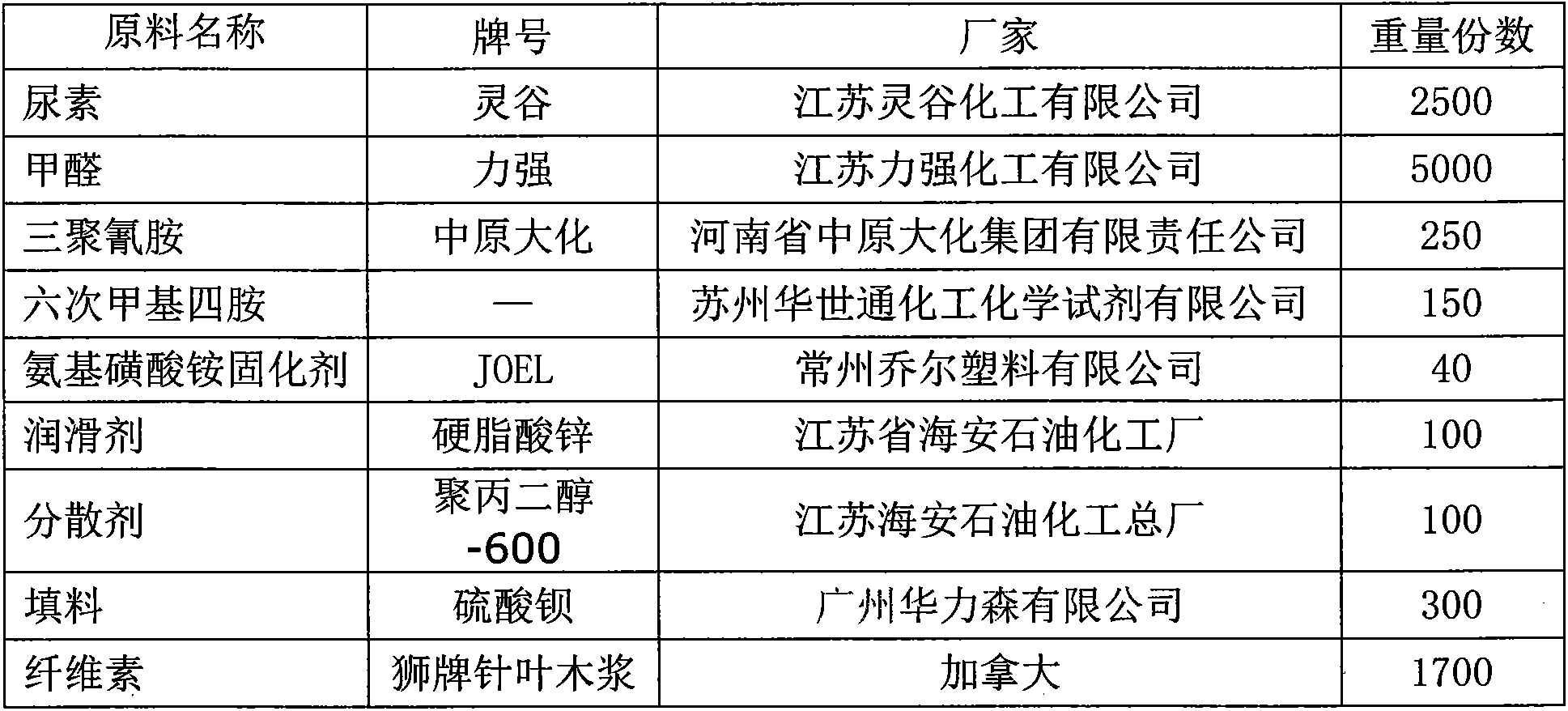

Method used

Image

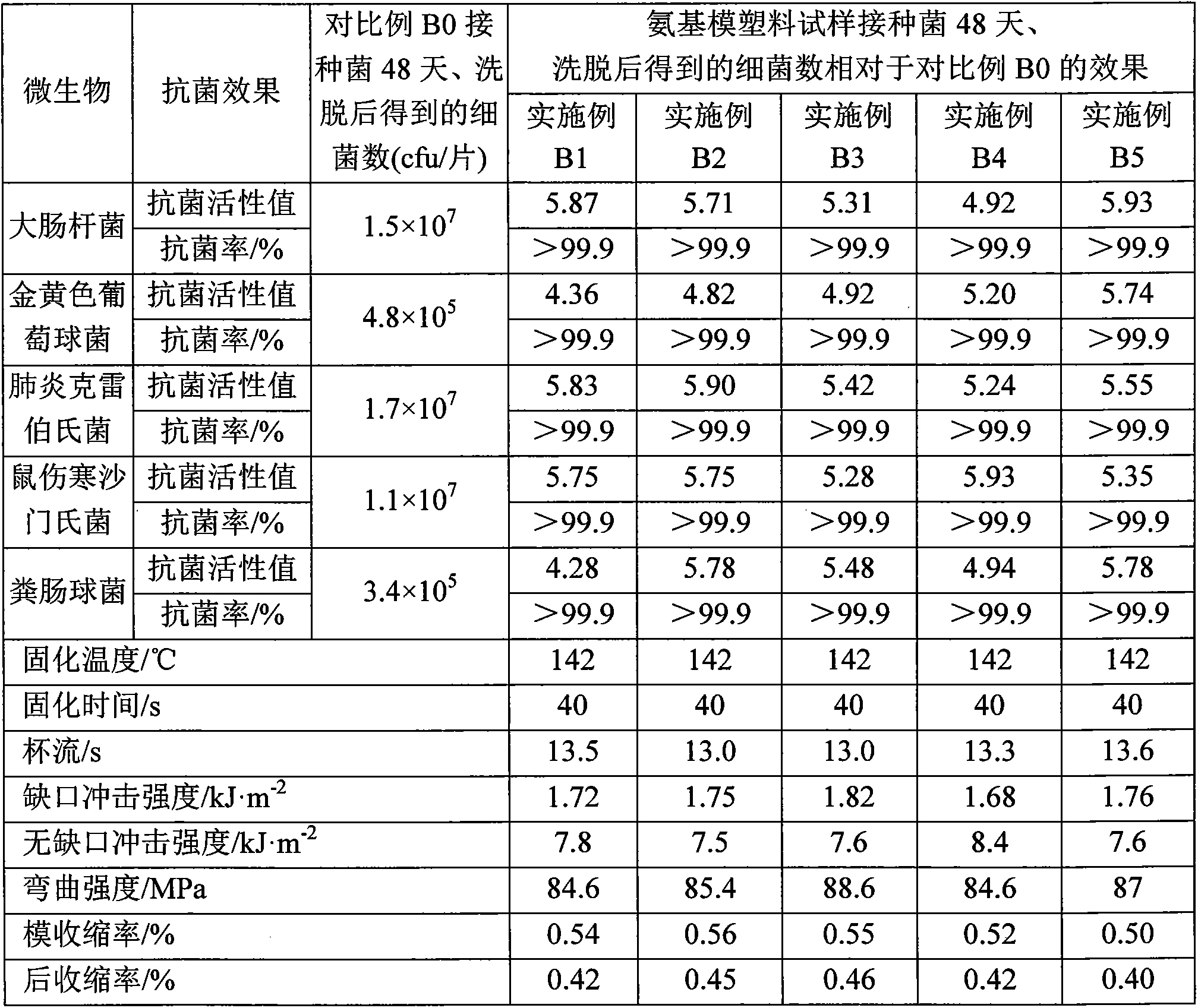

Examples

Embodiment A1

[0050] The preparation method of silver nanowire composite auxiliary agent sample A1 is as follows:

[0051] (1) Add 50 parts of distilled water into the reaction kettle, then add 20 parts of neopentyl glycol, heat to 40°C, add 0.6 parts of hexamethylenetetramine to adjust the pH value to 8.5±0.1, and obtain buffered neopentyl glycol coupling agent solution;

[0052] (2) Keep the reactor at 40°C, add 10 parts of silver nanowires and 10 parts of active nano-zinc oxide into the buffered neopentyl glycol solution, control the temperature of the material at 45°C, stir for 25 minutes, and cool to room temperature through the jacketed water of the reactor , through infiltration and coupling to prepare silver nanowire composite antibacterial additives.

Embodiment A2

[0054] The preparation method of silver nanowire composite auxiliary agent sample A2 is as follows:

[0055] (1) Add 50 parts of water into the reaction kettle, then add 20 parts of neopentyl glycol, heat to 40°C, add 0.6 parts of hexamethylenetetramine to adjust the pH value to 8.5±0.1, and obtain buffered neopentyl glycol coupling agent solution;

[0056] (2) Keep the reactor at 40°C, add 15 parts of silver nanowires and 5 parts of active nano-zinc oxide into the buffered neopentyl glycol solution, control the temperature of the material at 45°C, stir for 25 minutes, and cool to room temperature through the jacketed water of the reactor , through infiltration and coupling to prepare silver nanowire composite antibacterial additives.

Embodiment A3

[0058] The preparation method of silver nanowire composite auxiliary agent sample A3 is as follows:

[0059] (1) Add 50 parts of water into the reaction kettle, then add 25 parts of neopentyl glycol, heat to 40°C, add 0.7 parts of hexamethylenetetramine to adjust the pH value to 8.5±0.1, and obtain buffered neopentyl glycol coupling agent solution;

[0060] (2) Keep the reactor at 40°C, add 20 parts of silver nanowires and 5 parts of active nano-zinc oxide into the buffered neopentyl glycol solution, control the temperature of the material at 45°C, stir for 25 minutes, and cool to room temperature through the jacketed water of the reactor , through infiltration and coupling to prepare silver nanowire composite antibacterial additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com