Recombinant bacillus subtilis producing micromolecular hyaluronic acid

A technology of Bacillus subtilis and hyaluronic acid, which is applied in the field of bioengineering, can solve the problems of infection risk of animal epidemic sources, poor product quality, and high price, and achieve the effects of large application advantages, reduced viscosity, and easy purification and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Construction of integrated recombinant plasmid pAX01-hasA

[0035] The hyaluronic acid synthase hasA gene used in the present invention is derived from Streptococcus zooepidemicus ATCC 35246, and the Streptococcus zooepidemicus strain is inoculated in 5ml of M17 liquid medium and cultured at 37° C. and 200 rpm for 16 hours. The bacteria were collected, and the genomic DNA of Streptococcus zooepidemicus was extracted using a bacterial genome extraction kit.

[0036] According to the published genome information sequence, primers hasA-F / hasA-R were designed respectively, and the extracted genomic DNA was used as a template to amplify hasA gene using standard PCR amplification system and procedures.

[0037] Primer sequence information: 5'-3' direction

[0038] hasA-F: CGCGGATCCATGAGAACATTAAAAAACCTCATAAC

[0039] hasA-R: TGCATGCATTTATAATAATTTTTACGTGTTCC

[0040] BamHI and SacII restriction enzyme sites were introduced at both ends of the upstream and downstrea...

Embodiment 2

[0041] Example 2 Construction of recombinant plasmid pP43NMK / tuaD-glmU-glmS

[0042] Bacillus subtilis 168 strain was inoculated in 5ml LB medium, cultured at 37°C and 200rpm for 16h. The bacteria were collected, and the genomic DNA of Streptococcus zooepidemicus was extracted using a bacterial genome extraction kit. According to the published genome information sequence of Bacillus subtilis 168, primers tuaD-F / tuaD-R, glmU-F / glmU-R and glmS-F / glmS-R were designed respectively. Introduce KpnI restriction enzyme site and P43 RBS sequence (AAGAGAGGAATGTACAC) at the 5 end of upstream primer tuaD-F, introduce XhoI and SacI restriction enzyme site at the 5 end of downstream primer tuaD-R; The SacI restriction site and P43 RBS sequence were introduced into the 5 end of F, the XhoI and XbaI restriction site were introduced into the 5 end of the downstream primer glmU-R; the SpeI (XbaI) was introduced into the 5 end of the upstream primer glmS-F The same tail enzyme) restriction enz...

Embodiment 3

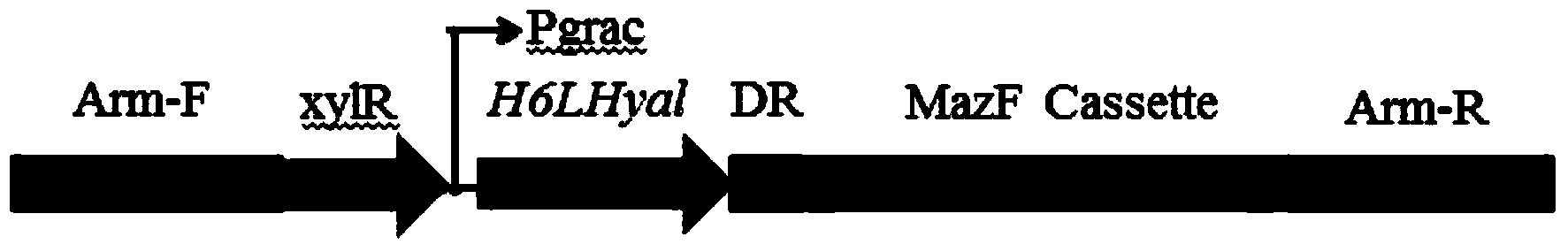

[0054] Example 3 Construction of leech hyaluronidase LHyal gene integration fragment

[0055] The toxin gene mazF derived from Escherichia coli and the bleomycin resistance gene Zeocin were used as dual selection markers to construct a traceless transformation fragment XMZ (SEQ ID NO.6) of the Bacillus subtilis genome. The mazF gene is placed under the control of the xylose-induced promoter Pxyl, and the specific operations are as follows: design primer pairs Pxyl-F / R, mazF-F / R and Zeo-F / R, respectively amplify xylR+Pxyl (xylose repressed protein and promoter) fragments, mazF and Zeocin fragments, the specific operating procedures are as follows: 2 μl of xylR+Pxyl and mazF fragments were mixed in a PCR tube, and 21 μl and 25 μl of sterile water were added to 2 x super pfu Master Mix (Hangzhou Baosai Biotechnology Co., Ltd. Co., Ltd.), mix well and place in a PCR instrument, and run according to the following program: 94°C for 3 minutes, [94°C for 30s, 50°C for 30s, 72°C for 1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com