Supported palladium catalyst and preparation method and application thereof

A technology of supported palladium and catalyst, applied in the field of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] For the synthesis of palladium nanorods, 0.1 mmol of palladium acetylacetonate was dissolved in 10 mL of oleylamine, and 0.5 mmol of N,N-diethylaniline borane was injected, and the solution obviously changed from colorless to brown-black. The temperature of the solution was adjusted to 90° C. and reduced for 30 minutes. After the temperature dropped to room temperature, ethanol was added to settle the nanoparticles, and the nanoparticles were obtained by centrifugation. Then, the nanoparticles were washed successively with distilled water and ethanol, and dried to obtain brown-black powder (palladium nanocrystals). Take 8 mg of the powder and disperse it in 10 mL of n-hexane, add 72 mg of graphene, load at room temperature, and finally centrifuge and dry to obtain the supported palladium catalyst, in which the mass percentage of palladium is 10%.

Embodiment 2

[0052] For the synthesis of palladium nanorods, 0.1 mmol palladium acetylacetonate was dissolved in 10 mL oleylamine, and 0.8 mmol N,N-diethylaniline borane was injected into the above solution, and the solution obviously changed from colorless to brown black. The temperature of the solution was adjusted to 50° C. and reduced for 45 minutes to obtain nanocrystals. After the temperature dropped to room temperature, ethanol was added to settle the nanoparticles, and the nanoparticles were obtained by centrifugation. The nanoparticles were washed successively with distilled water and ethanol, and dried to obtain a brown-black powder (palladium nanocrystal). Take 8 mg of powder and disperse it in 10 mL of n-hexane, add 32 mg of graphene, load at room temperature, and finally centrifuge and dry to obtain the supported palladium catalyst, in which the mass percentage of palladium is 20%.

Embodiment 3

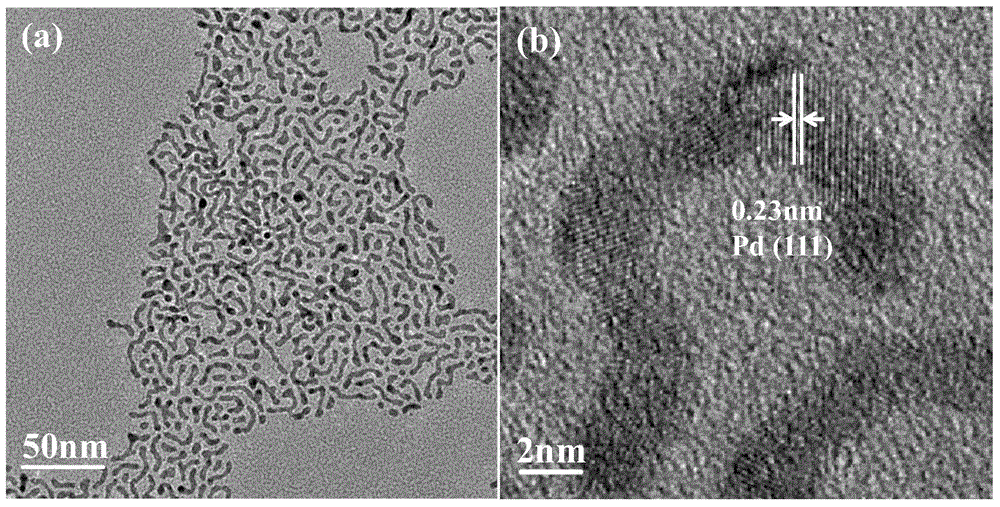

[0054] For the synthesis of palladium nanorods, 0.1 mmol of palladium acetylacetonate was dissolved in 10 mL of oleylamine, and 1 mmol of N,N-diethylaniline borane was injected into the solution, and the solution obviously changed from colorless to brown-black , reacted at room temperature for 1 hour. Then ethanol was added to make the nanoparticles settle down, and the nanoparticles were obtained by centrifugal separation. The nanoparticles were washed successively with distilled water and ethanol, and dried to obtain a brown-black powder (palladium nanocrystal), and its transmission electron microscope picture is as follows: figure 1 As shown, it can be seen from the figure that the prepared nanoparticles are nanorods with uniform size and good dispersion. figure 1 In (b), the lattice fringes of palladium can be clearly seen, and the lattice spacing is about 0.23 nm, which corresponds to the (111) crystal plane of palladium. Take 8 mg of powder and disperse it in 10 mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com