Tackifier for drilling fluid and preparation method thereof

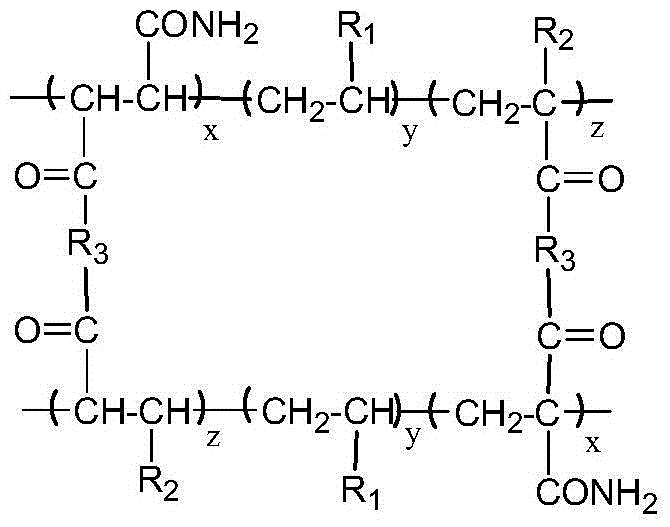

A technology for tackifier and drilling fluid, which is applied in the field of synthesizing treatment agent for oilfield drilling fluid, can solve the problems of insignificant increase in shear force, adverse environmental impact, decreased viscosity increasing effect, etc. ability, the effect of reducing the filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

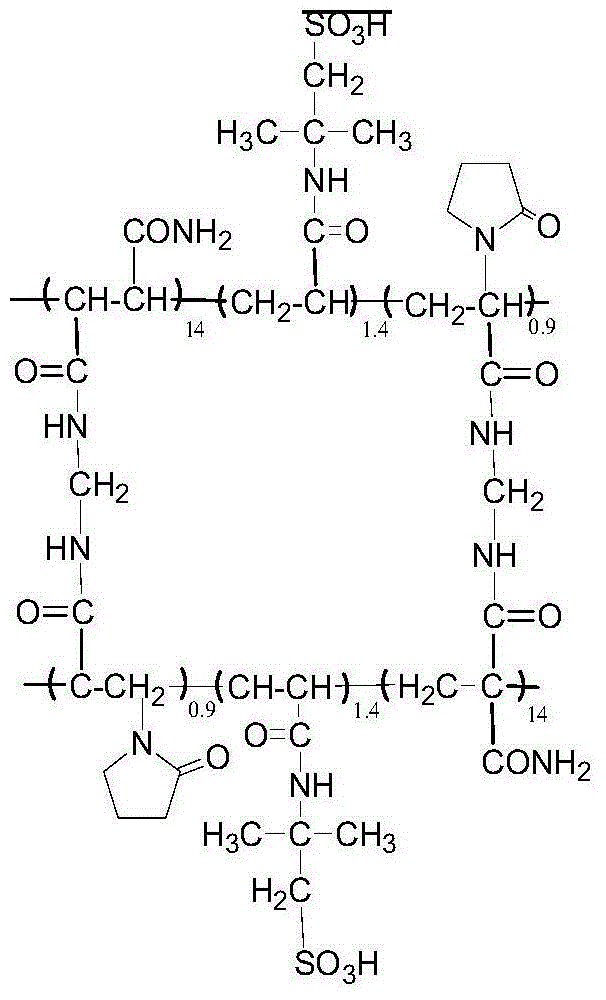

[0027] (1) 100g of acrylamide, 30g of A12-acrylamido-2-methylpropanesulfonic acid and 10g of B1N-vinylpyrrolidone were dissolved in 120g of clear water, and the pH value was adjusted to 7 with sodium hydroxide;

[0028] (2) Dissolve 0.14g of C1N, N-methylenebisacrylamide in 5g of clear water;

[0029] (3) Dissolve 0.14g of D1 isopropanol in 5g of clear water, add to the reaction vessel together with the solution obtained in step (1) and step (2), and heat up to 30°C;

[0030] (4) 0.93g ammonium persulfate and 0.47g sodium bisulfite were dissolved in 5g clear water respectively;

[0031] (5) Add the initiator solution obtained in step (4) into the reaction vessel of step (3) successively, and polymerize for 30 minutes to obtain a tackifier product with a solid phase content of 50%, which is dried and pulverized to obtain Viscosifier APN-1 for drilling fluid, its structural formula is:

[0032]

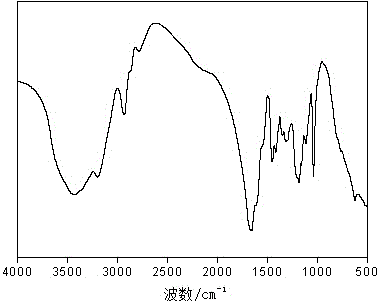

[0033] The tackifier product that embodiment 1 reaction obtains is purified, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com