Method for preparing microbial liquid fertilizer fermented animal dung transformed organic fertilizer

A technology of animal manure and microorganisms, which is applied in the preparation of organic fertilizers, the treatment of biological organic parts, and organic fertilizers, etc., can solve the problems that plants cannot maximize the use of soil nutrients, waste of soil organic matter, and increase the cost of food production. The effect of promoting root growth and cell division, enhancing fertilizer efficiency and improving nitrogen fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

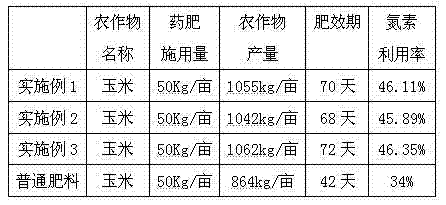

Examples

Embodiment 1

[0025] 1.1. In parts by weight, take 0.8 part of EM original dew, add 0.8 part of saccharomyces with a viable count of 200 million strains / ml, 0.8 part of photosynthetic bacteria with a viable count of 90 million strains / ml, add 0.8 part of live Actinomycetes with a bacterial count of 200 million strains / ml and 0.8 parts of rhizobia with a viable bacterial count of 400 million strains / ml were added, mixed evenly, and left to stand for 1.5 hours to obtain a microbial liquid fertilizer;

[0026] 1.2. In parts by weight, take 800 parts of pig manure powder, 200 parts of crop straw powder and 380 parts of water and mix evenly, add all the microbial liquid fertilizer prepared in step 1.1, and carry out anaerobic fermentation at room temperature for 12 days to obtain a fermented material;

[0027] 1.3. In parts by weight, add 0.8 part of saccharomyces with a viable count of 200 million strains / ml and 0.8 part of photosynthetic bacteria with a viable count of 90 million strains / ml wi...

Embodiment 2

[0030] 1.1. In parts by weight, take 0.5 part of EM original dew, add 1 part of actinomycetes with 350 million strains / ml of live bacteria and 0.5 part of rhizobium with 600 million strains / ml of viable bacteria, mix evenly, Stand still for 1h to obtain microbial liquid fertilizer;

[0031] 1.2, in parts by weight, get 750 parts of chicken manure powder, 250 parts of husk grass powder and 350 parts of water and mix evenly, add all the microbial liquid fertilizer prepared in step 1.1, and carry out anaerobic fermentation at room temperature for 4 days, Get a fermented material;

[0032] 1.3. In parts by weight, add 1 part of saccharomyces with a viable count of 100 million strains / ml and 0.5 part of photosynthetic bacteria with a viable count of 100 million strains / ml to the primary fermented material of anaerobic fermentation in step 1.2 , carry out the second anaerobic fermentation at room temperature, the fermentation time is 10 days, obtain the fermented organic fertilizer...

Embodiment 3

[0035] 1.1. In parts by weight, take 1 part of EM original dew, add 0.5 part of actinomycetes with a viable count of 100 million strains / ml and 1 part of rhizobium with a viable count of 200 million strains / ml, mix evenly, Stand still for 2 hours to obtain microbial liquid fertilizer;

[0036] 1.2, in parts by weight, get 850 parts of chicken manure powder, 150 parts of weed powder and 400 parts of water and mix evenly, add all the microbial liquid fertilizer prepared in step 1.1, and carry out anaerobic fermentation at room temperature for 15 days to obtain primary fermented material;

[0037] 1.3. In parts by weight, add 0.5 part of saccharomyces with a viable count of 250 million strains / ml and 1 part of photosynthetic yeast with a viable count of 310 million strains / ml to the primary fermented material of anaerobic fermentation in step 1.2. Bacteria, the second anaerobic fermentation is carried out at room temperature, and the fermentation time is 4 days to obtain animal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com