High-purity grade diiodomethane purifying method used for photovoltaic material

A diiodomethane and purification method technology, applied in chemical instruments and methods, disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve problems such as unworthy promotion, large environmental impact, cumbersome operation, etc., and achieve stable product quality , Yield improvement, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

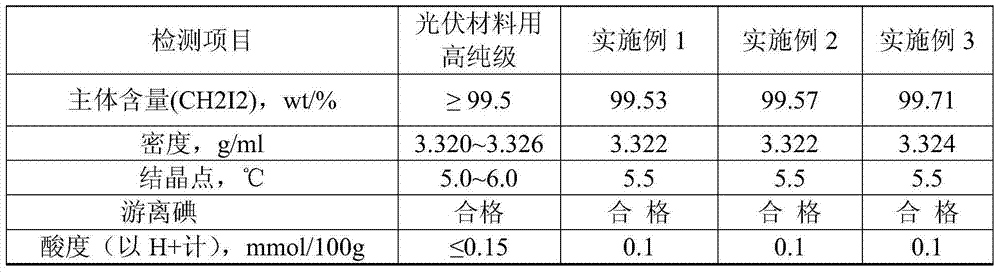

Examples

Embodiment 1

[0023] (1) Preparation of modified 2-acrylamide-2-methylpropanesulfonic acid copolymer adsorption column:

[0024] Take 100g of sodium carbonate, add 1750ml of pure water, 150ml of diisooctyl phthalate, and 500ml of ethyl acetate, add 500g of 2-acrylamide-2-methylpropanesulfonic acid to the dipping solution at room temperature, and then immerse for 15h After filtering, washing twice with 500ml of 18.2MΩ·cm ultrapure water, drying at 105°C for 12h, 553g of modified 2-acrylamide-2-methylpropanesulfonic acid copolymer is obtained, which is packed in a column and ready for use.

[0025] (2) Purification of diiodomethane:

[0026] 1000g of industrial grade diiodomethane raw material with a content of 95.0wt% is adsorbed through an adsorption column containing a modified 2-acrylamide-2-methylpropanesulfonic acid copolymer medium at a temperature of 0.22MPa and 20°C, and the filtrate is purified by quartz The rectification device removes the front distillate under the vacuum condition of -...

Embodiment 2

[0028] (1) Preparation of modified 2-acrylamide-2-methylpropanesulfonic acid copolymer adsorption column: Take 150g of sodium carbonate, add 2000ml of pure water, 200ml of diisooctyl phthalate, and 750ml of ethyl acetate. Add 500g of 2-acrylamide-2-methylpropanesulfonic acid to the dipping solution at room temperature, immerse for 17.5h, filter, wash twice with 600ml of 18.2MΩ·cm ultrapure water, and dry at 105°C for 12h, that is 561 g of modified 2-acrylamide-2-methylpropanesulfonic acid copolymer was obtained, which was packed in a column for use.

[0029] (2) Purification of diiodomethane:

[0030] 1000g of industrial grade diiodomethane raw material with a content of 95.0wt% is adsorbed through an adsorption column containing a modified 2-acrylamide-2-methylpropanesulfonic acid copolymer medium at a temperature of 0.17MPa and 23°C, and the filtrate is purified by quartz The distillation device removes the front distillate under the vacuum condition of -0.085MPa, and collects t...

Embodiment 3

[0032] (1) Preparation of modified 2-acrylamide-2-methylpropanesulfonic acid copolymer adsorption column:

[0033] Take 200g of potassium carbonate, add 2250ml of pure water, 250ml of diisooctyl phthalate, and 1000ml of ethyl acetate, add 500g of 2-acrylamide-2-methylpropanesulfonic acid to the dipping solution at room temperature. After immersing for 20 hours After filtering, washing twice with 700ml of 18.2MΩ·cm ultrapure water, drying at 105°C for 12h, 583g of modified 2-acrylamide-2-methylpropanesulfonic acid copolymer is obtained, which is packed in column and ready for use.

[0034] (2) Purification of methyl iodide:

[0035] 1000g of industrial grade diiodomethane raw material with a content of 95.0wt% is adsorbed through an adsorption column containing a modified 2-acrylamide-2-methylpropanesulfonic acid copolymer medium at a temperature of 0.12MPa and 20°C, and the filtrate is purified by quartz The rectification device removes the front fraction under the vacuum condition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com