Degradable perlite tableware and preparation method thereof

A technology of perlite and perlite powder, which is applied in the field of perlite degradable tableware and its preparation, can solve the problems of increased manufacturing difficulty and production cycle, high transportation cost, and complicated preparation methods, so as to achieve good filling fluidity and reduce production The effect of simple cost and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

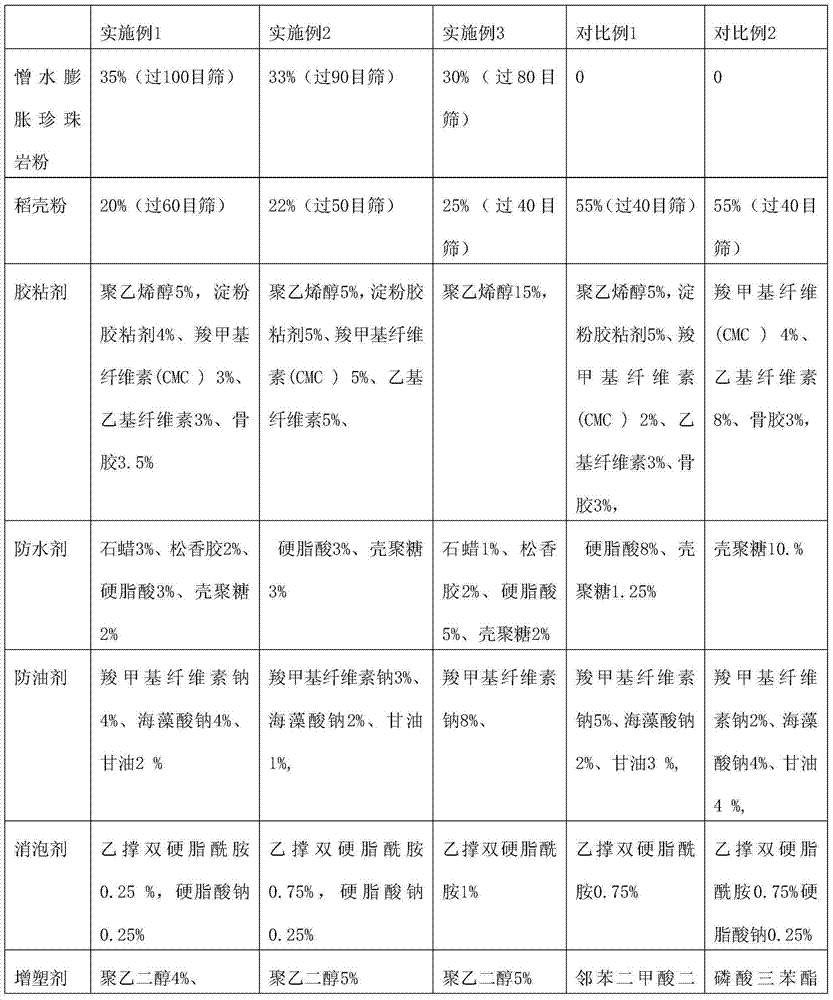

[0030] The raw materials of Examples 1-3 and the components of Comparative Examples 1 and 2 are shown in Table 1.

[0031] Table 1 (%wt)

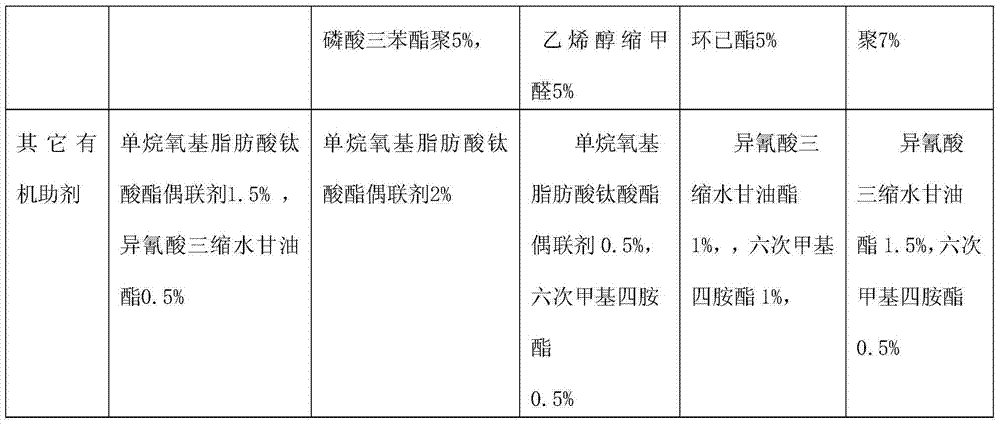

[0032]

[0033]

[0034] making process:

[0035] Stir and mix the raw material components of Examples 1-3 and Comparative Examples 1 and 2 respectively, control the moisture content of the rice husk powder to 4-5%wt, and then directly put it into the mold of the thermocompression molding machine for one-time addition. Degradable tableware 1-5 is obtained after pressure, pressure relief and exhaust, secondary pressure adding, pressure maintaining and shaping, and then conventional ultraviolet disinfection and edge removal machine edge treatment. The pressure of the two pressurizations is 24- 25Mpa, the time for one pressurization is 8-10s, the time for pressure relief and exhaust is 2-3s, the time for secondary pressurization is 8-10s, the time for holding pressure and setting is 8-10s, and the upper mold temperature of the mold is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com