Separation and determination method of aromatics and sulfur-containing aromatics in heavy oil aromatics

A separation method, technology of sulfur aromatics, applied in the direction of material separation, measuring devices, analysis materials, etc., can solve the problems of ineffective vaporization and inaccurate quantitative results of gas chromatography, and achieve the effect of shortening the separation and identification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

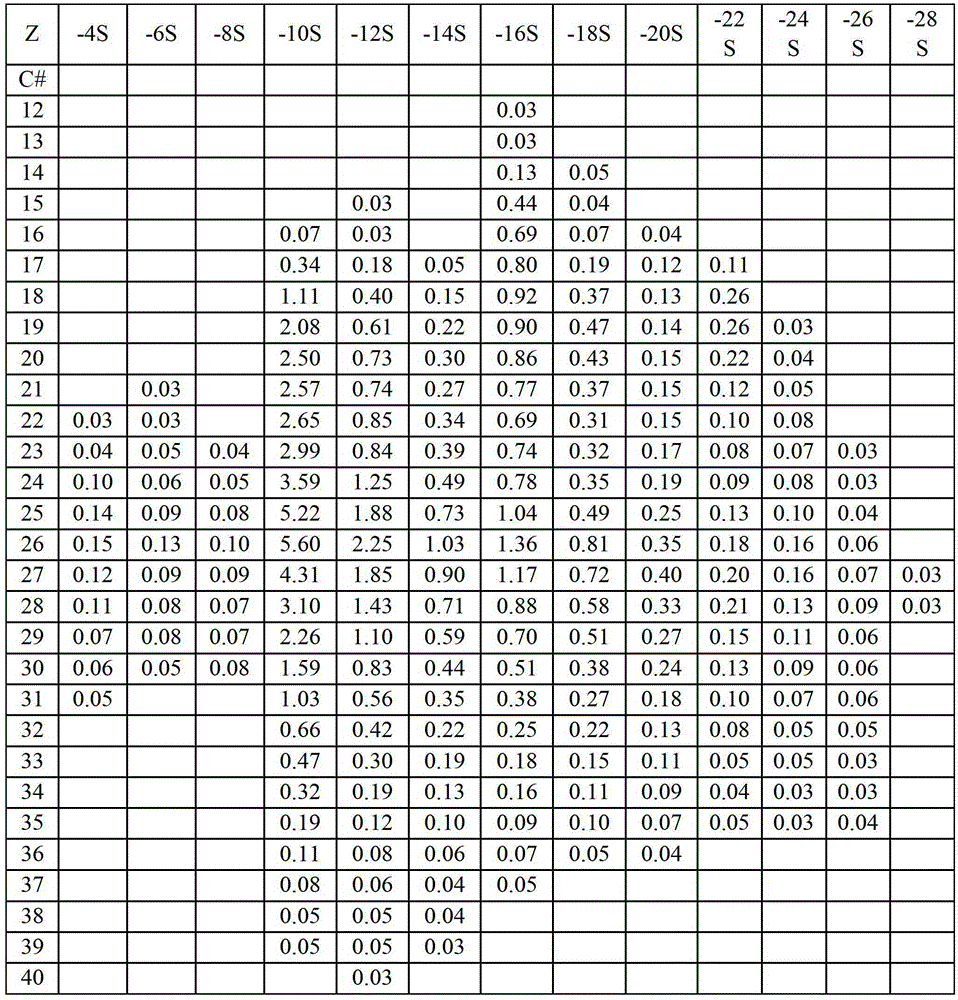

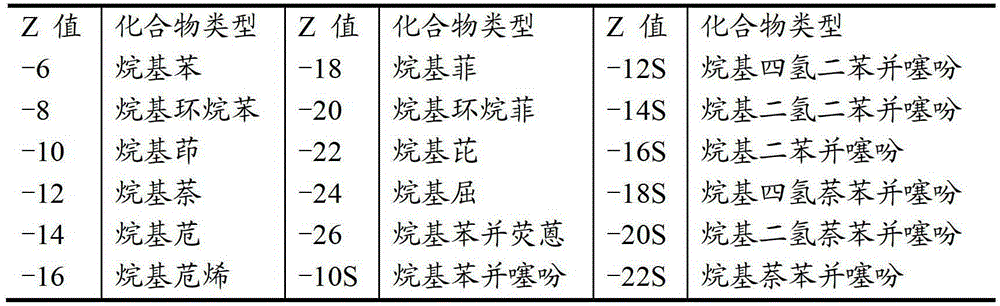

Image

Examples

preparation example Construction

[0015] The preparation method of the stationary phase of the present invention is as follows: calcining alumina at 400-700° C. for 3-6 hours, and if silicon dioxide is used, calcining it at 120-300° C. for 3-6 hours in advance. Dissolve palladium chloride in water at 50-90°C, then add alumina or a mixture of alumina and silica, mix well and then impregnate for 10-30 hours, the liquid / solid ratio of impregnation is 1.5-4.0mL / g, Then dry the impregnated solid at 100-300° C. for 2-5 hours.

[0016] The invention firstly separates the heavy oil, and separates the saturated hydrocarbon, aromatic hydrocarbon and colloid components therein. The heavy oil is vacuum distillate oil, atmospheric residual oil, vacuum residual oil, deasphalted oil, catalytic cracking oil slurry or hydrotreated oil.

[0017] If the heavy oil is residual oil, according to the method of "Petrochemical Analysis Methods" (Science Press, 1990: 31) edited by Yang Cuiding et al., use n-heptane to precipitate the ...

example 1

[0042] Preparation of stationary phase: γ-alumina (produced by Sinopharm Chemical Reagent Co., Ltd.) was roasted at 500°C for 5 hours, and 0.5g PdCl 2 Dissolve in 20mL of water at a temperature of 80°C, add to 9.5g of calcined γ-alumina after fully dissolving, stir evenly, let stand for immersion for 24 hours, and dry at 150°C for 3 hours to obtain the stationary phase A of the present invention , where PdCl 2 The content is 5% by mass.

[0043] The method of the invention is used to carry out solid phase extraction to separate aromatics and sulfur-containing aromatics in heavy oil.

[0044] (1) Separation of aromatic components in heavy oil

[0045] Separation of aromatics in heavy oil by alumina column chromatography. Take 3g of Saudi medium vacuum wax oil and dissolve it in 50mL of n-hexane to prepare a raw material solution, and add the raw material solution to a column chromatography filled with 100g of γ-alumina. Use normal hexane, dichloromethane and benzene / ethanol...

example 2

[0055] Preparation of stationary phase: roast 6g of γ-alumina at 550°C for 4 hours, 3.5g of silica at 120°C for 4 hours, and 0.5g of PdCl 2 Dissolve in 20mL of water at a temperature of 80°C, add to the roasted γ-alumina and silica mixture after fully dissolving, stir evenly, let it stand for immersion for 24 hours, and dry at 300°C for 5 hours to obtain the stationary phase B. where PdCl 2 The content is 5% by mass.

[0056] (1) Separation of aromatic components in heavy oil

[0057] After deasphalting the Tahe vacuum residue oil with n-heptane, use silver nitrate modified silica gel (see CN102079987A for the preparation method) as the stationary phase to separate the aromatics in the deasphalted oil by solid phase extraction. The specific operation is as follows: take 3g of raw material The deasphalted oil was dissolved in 50mL of n-hexane to prepare a raw material solution, and the raw material solution was added to a solid-phase extraction column filled with 100g of silv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com