Fluorescent graft degradable block polyurethane, bone repair material and preparation method thereof

A fluorescent, polyurethane technology, applied in luminescent materials, chemical instruments and methods, pharmaceutical formulations, etc., can solve the problems of expensive LDI raw materials, difficult promotion and application, etc., and achieve the effect of convenient biodegradability and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

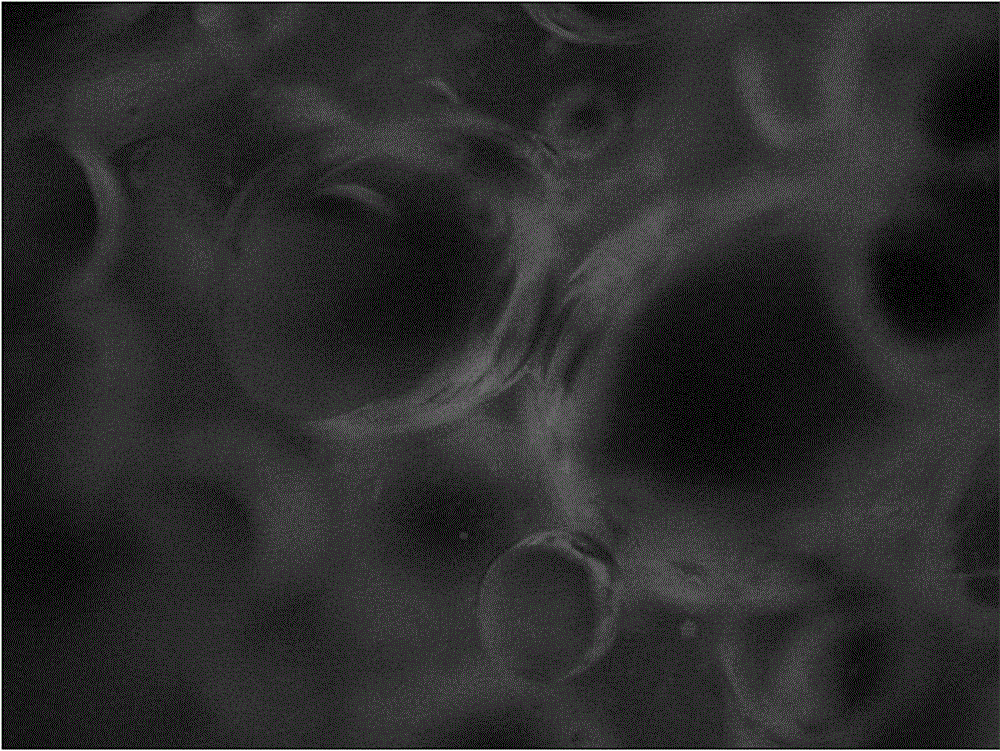

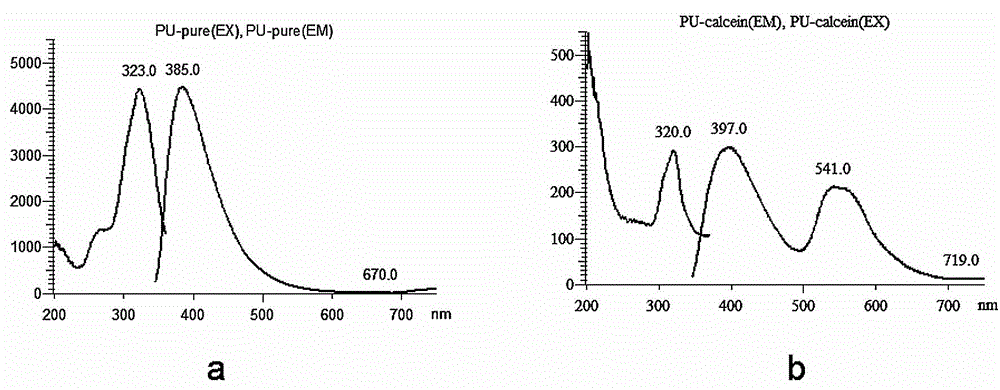

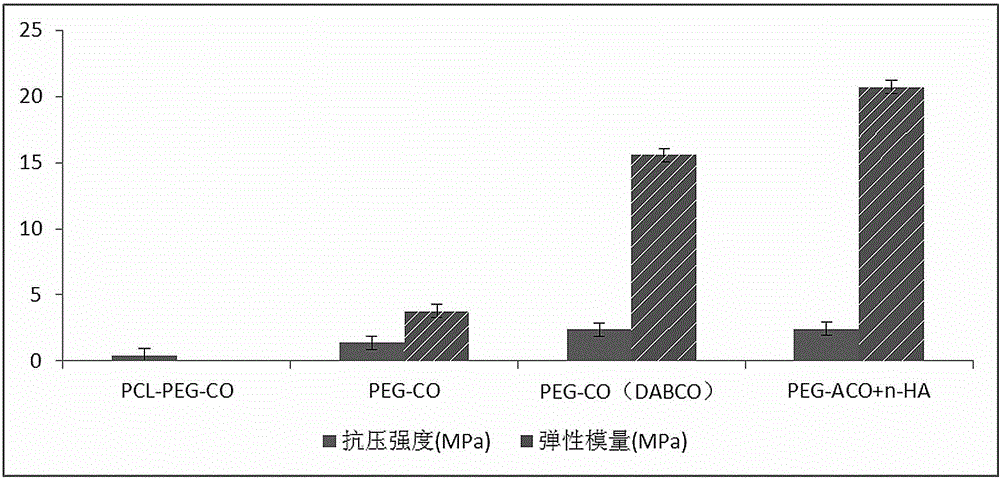

[0022] Blend 40.0g polycaprolactone diol (PCL) (molecular weight 2000), 16.0g polyethylene glycol (PEG) (molecular weight 400) and 15.6g castor oil (CO) into a three-necked flask filled with nitrogen, then add 52.8g of isophorone diisocyanate (IPDI) (molecular weight 222.28), reacted at 70°C for 0.5h, then added 2.4g of calcein, mixed and stirred for 2h to prepare a fluorescent group-containing block polyurethane prepolymer. Then add 4 drops (about 0.2ml) of stannous octoate and continue to stir for 1 hour, then add 2ml of 1,4-butanediol and continue to react for 3 hours, then add 0.2ml of water as a foaming agent and continue to react for 0.5 hours, collect the sample and place it in an oven at 90°C Medium aging and drying for 48 hours to obtain the corresponding target product of fluorescent grafted degradable block polyurethane. The fluorescence micrographs and fluorescence spectra of the fluorescent grafted degradable block polyurethane are shown in Fig. figure 1 and f...

Embodiment 2

[0026] Blend 10.0g polycaprolactone diol (PCL) (molecular weight 1000), 12.0g polyethylene glycol (PEG) (molecular weight 600) and 15.6g castor oil (CO) into a three-necked flask filled with nitrogen, and slowly add 30wt% (about 28.5g) nano-hydroxyapatite powder, mix well, add 26.4g isophorone diisocyanate (IPDI) (molecular weight 222.28), react at 70°C for 0.5h, add 1.6g calcein and mix and stir 2h Preparation of block polyurethane prepolymers containing fluorescent groups. Then add 2 drops (about 0.1ml) of triethylenediamine and continue to stir for 1 hour, then add 2ml of 1,4-butanediol to continue the reaction for 3 hours, then add 0.2ml of water as a foaming agent to continue the reaction for 0.5 hours, and place the sample in 110 It was cured and dried in an oven at ℃ for 48 hours to obtain the target segmented polyurethane.

Embodiment 3

[0028] Blend 5.0g polycaprolactone diol (PCL) (molecular weight 500), 20.0g polyethylene glycol (PEG) (molecular weight 1000) and 20.0g castor oil (CO) into a three-necked flask filled with nitrogen, then add 26.4g of lysine diisocyanate (LDI) (molecular weight: 226.23), reacted at 70°C for 0.5h, then added 1.2g of fluorescein isothiocyanate and stirred for 2h to prepare a block polyurethane prepolymer containing fluorescent groups. Then add 2 drops (about 0.1ml) of stannous octoate and 1 drop (about 0.05ml) of triethylenediamine and continue to stir for 1h, then add 2ml of ethylene glycol and continue to react for 3h, then add 0.2ml of water as a foaming agent and continue to react for 0.5 h, the sample was collected and placed in an oven at 90°C for aging and drying for 48 hours to obtain the target block polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com