Preparation method of silicon-carbon composite negative electrode material of lithium ion battery and application of silicon-carbon composite negative electrode material

A lithium-ion battery, silicon-carbon composite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of nano-silicon falling off, and achieve high specific capacity, high initial charge and discharge efficiency, and excellent cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

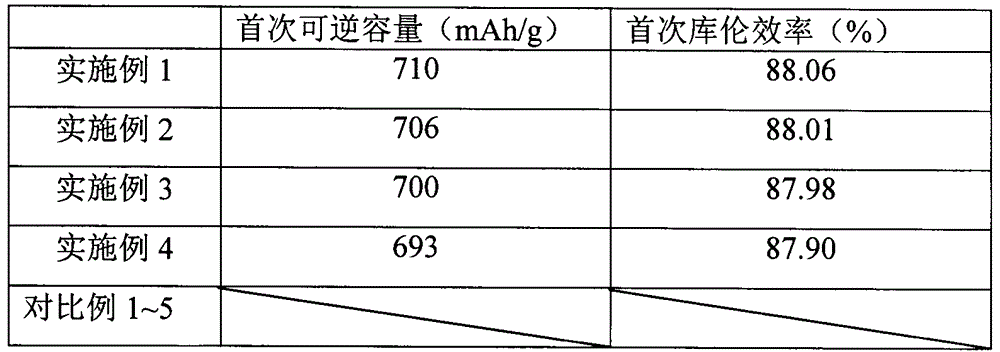

Embodiment 1

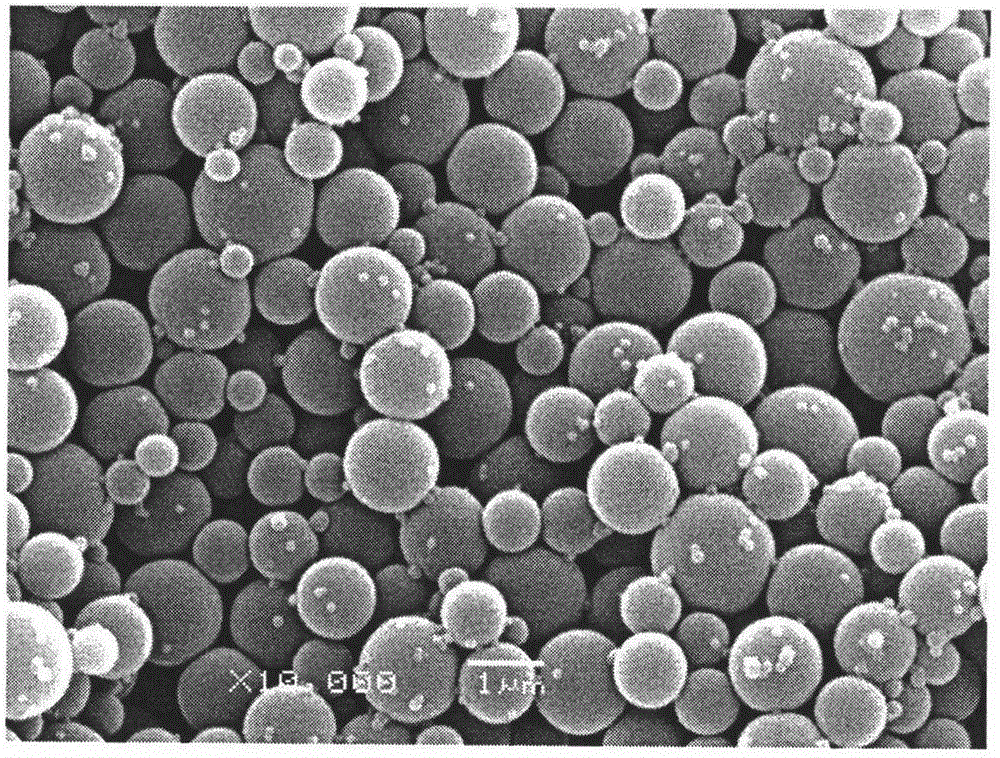

[0048] In the presence of an ethanol dispersion medium, use a grinder to grind silicon, and add maleic acid to the silicon grinding solution to control the pH value of the silicon grinding dispersion to 5.8 and the mass solid content to 10.3%, and set aside. The average particle size of the silicon particles in the silicon polishing liquid is 150nm.

[0049] Adding 121.3g mass solid content is 10.3% nano-silicon dispersion liquid and 12.5g silane coupling agent γ-methacryloxypropyltrimethoxysilane (trade name: KH570) in the glass reactor, then successively Add 12.5g of styrene solution with 0.54g of dibenzoyl peroxide dissolved in it and 2.5g of dodecyl mercaptan (TDM) into the reaction kettle, set the temperature at 73°C, stir at 150rpm, and keep the temperature for 10h. After cooling to room temperature, add 175g of styrene monomer to the solution, mix and stir, then purify and remove the ethanol in the mixed solution to obtain a hydrophobically treated nano-silicon dispersi...

Embodiment 2

[0054] (1) prepare nano-silicon dispersion liquid with embodiment one;

[0055] (2) Add 364.1g of nano-silicon dispersion liquid and 37.5g of silane coupling agent γ-methacryloxypropyl trimethoxysilane (trade name: KH570) that step (1) obtains in glass reactor, then 1.12g dibenzoyl peroxide (BPO) was gently stirred and dissolved in 37.5g styrene and added to the reactor, and finally 0.75g dodecyl mercaptan (TDM) was added to the reactor. At 73° C. and a stirring speed of 150 rpm, the reaction was kept for 10 h, and then cooled to room temperature. Add 175g styrene to this solution and mix and stir, then purify and remove the ethanol of this mixed solution to get the nano-silicon dispersion liquid dispersed in styrene, and then complete the surface modification of nano-silicon, adopt GPC (Gel Permeation Chromatography), measuring the weight-average molecular weight of the surface polymer of modified nano-silicon is 15000.

[0056] Take by weighing 13.18g dibenzoyl peroxide an...

Embodiment 3

[0060] (1) prepare nano-silicon dispersion liquid with embodiment one;

[0061] (2) Add 364.1g of nano-silicon dispersion liquid obtained in step (1) and 37.5g of silane coupling agent γ-methacryloxypropyl trimethoxysilane (KH570) into the reactor, and then 0.56g of Stir and dissolve dibenzoyl oxide (BPO) into 18.75g of styrene, add 1.88g of dodecyl mercaptan (TDM) into the reaction kettle, set the reaction temperature at 73°C, keep the temperature for 15h, and then Cool to room temperature. Then add 175g of styrene monomer to this solution, mix and stir, then purify and remove the ethanol of this mixed solution to obtain nano-silicon dispersion liquid dispersed in styrene, and then complete the surface modification of nano-silicon, using GPC (Gel Permeation Chromatography), the weight average molecular weight of the surface polymer was determined to be 8500.

[0062] Take by weighing 13.18g dibenzoyl peroxide (BPO) and gently stir and dissolve in 75g acrylonitrile (AN), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com