Preparation method and application of multi-effect organic foliage conditioner

A conditioner and foliage technology, applied in the field of new agricultural means of production, can solve the problems of high value, high manufacturing cost of organic fertilizers, environmental pollution, etc., achieve low cost, improve economic and social benefits, and have a wide range of sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the multi-effect organic foliage conditioner of the present embodiment, the steps are as follows:

[0030] Mix wheat and corn stalk biochar with water at a mass ratio of 1:20 and stir evenly to obtain mixed solutions A and B, which are leached at 80-85°C for 3 hours (every Stir the mixed solution once in half an hour), then place it in a shaking table with a rotating speed of 180r / min and shake it at room temperature for 24 hours to obtain biochar extracts A and B, and perform microporous membrane filtration on the extracts A and B. The membrane pore size is 30-50 microns) and the solid residue is separated by suction filtration to obtain foliar conditioners A and B. Foliage conditioner A is dark black, its pH is 9.65, and the total organic carbon content TOC is 566.7mg / L; foliage conditioner B is brownish red, its pH is 9.44, and the total organic carbon TOC content is 333mg / L. Mix peanut shell biochar and water according to the mass ratio of...

Embodiment 2

[0041] Mix wheat straw biochar and water according to the mass ratio of 1:20 and stir evenly to obtain mixed solution A, which is leached at 80-85°C for 3 hours (mixed solution B is stirred once every half hour) ), and placed in a shaker with a rotating speed of 180r / min at room temperature for 24 hours to obtain wheat straw biochar extract liquid A, and suction filtered the extract liquid A to obtain liquid leaf conditioner A. The leaf conditioner A is dark black, its pH is 9.65, and the content of total organic carbon TOC is 566.7mg / L.

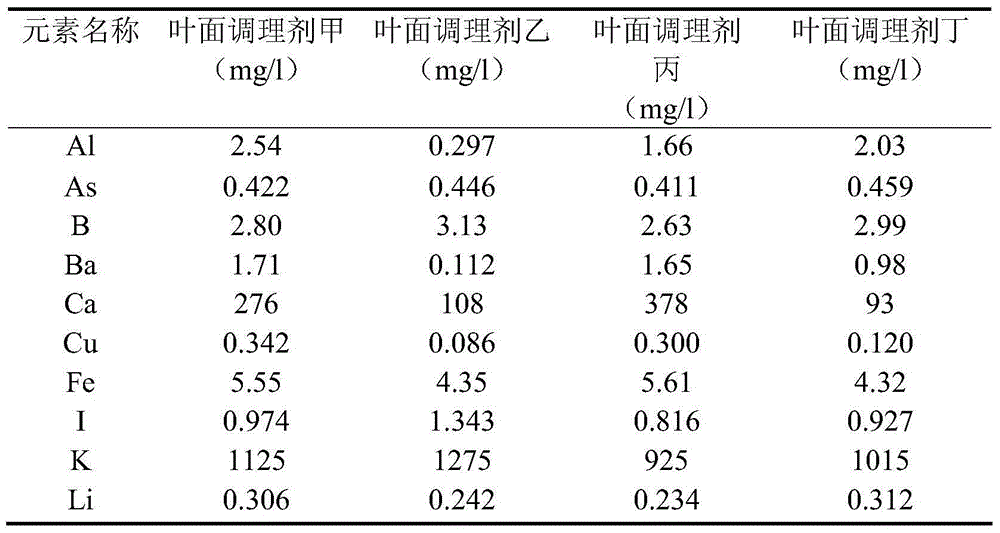

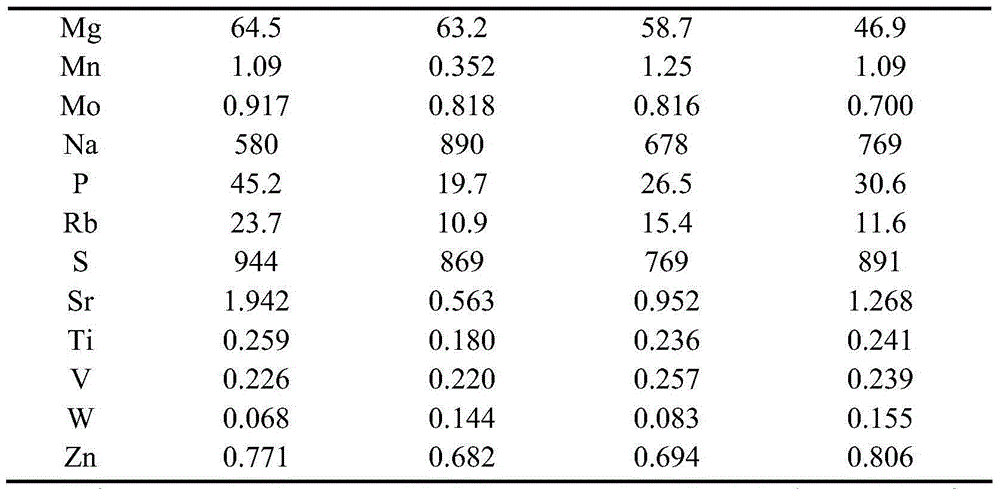

[0042] Carry out ICP analysis to foliar conditioner A, its result is shown in Table 1.

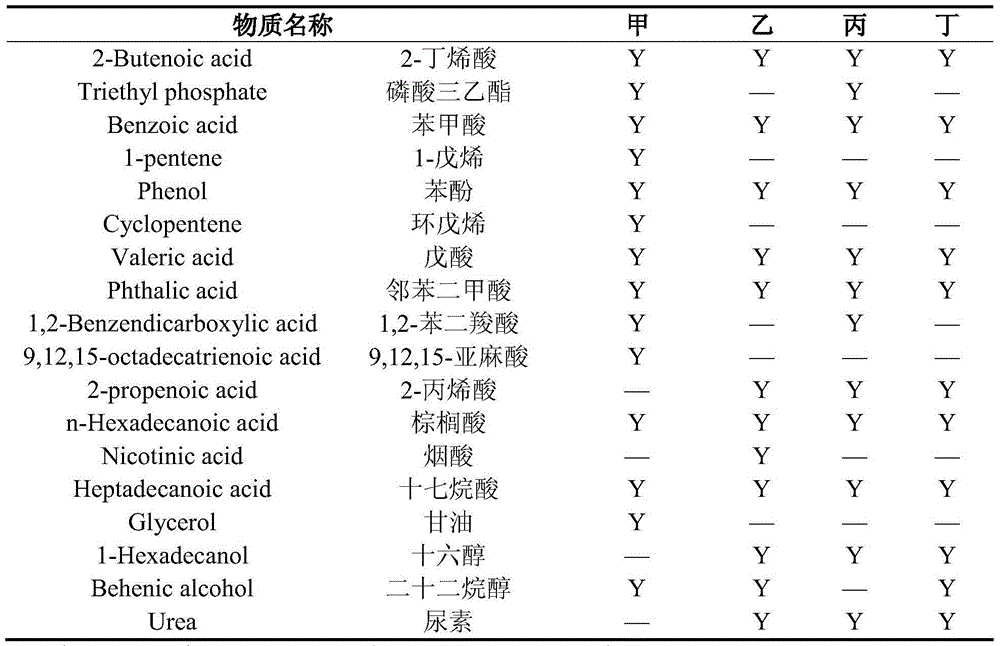

[0043] The leaf conditioner A was subjected to two-step derivatization after freeze-drying, and then analyzed by GC / MS. The analysis results are shown in Table 2. It can be seen from Table 2 that 14 substances were detected in foliar conditioner A, mainly including organic acids, phenols and alcohols.

[0044] After diluting foliage conditioner A with ...

Embodiment 3

[0052] Mix corn stalk biochar and water according to the mass ratio of 1:20 and stir evenly to obtain mixed solution B, which is leached at 80-85°C for 3 hours (mixed solution B is stirred once every half hour) ), and then placed in a shaker with a rotating speed of 180r / min and oscillated at room temperature for 24 hours to obtain corn stalk biochar extract solution B, which was subjected to suction filtration to obtain liquid foliar conditioner B. Leaf conditioner B is brownish red, its pH is 9.44, and the content of total organic carbon TOC is 333mg / L.

[0053] Carry out ICP analysis to foliage conditioner B, its result is shown in Table 1.

[0054] The foliar conditioner B was freeze-dried and derivatized in two steps, and analyzed by GC / MS. The analysis results are shown in Table 2. It can be seen from Table 2 that 12 substances were detected in foliar conditioner B, mainly including organic acids, phenols and alcohols.

[0055] Foliage conditioner B was diluted 25, 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com