Catharanthine tartrate preparation method

A technology of vinblastine and tartrate, applied in the direction of organic chemistry and the like, can solve the problems of being unsuitable for industrial production, low vinblastine yield, complicated purification steps and the like, and achieves high product yield, rapid dissolution and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

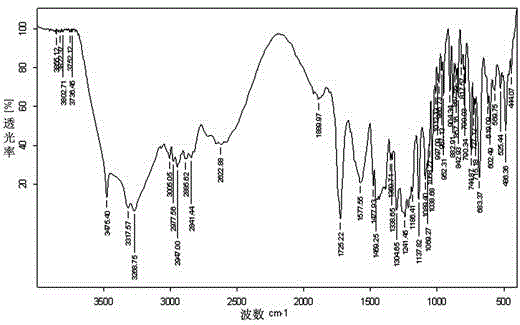

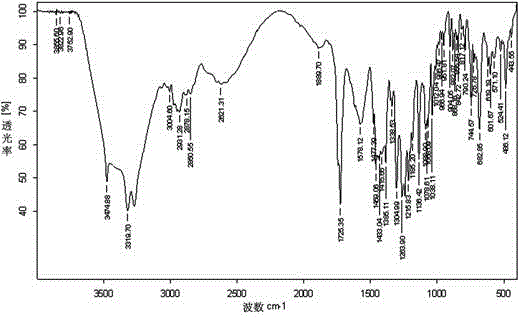

Image

Examples

Embodiment 1

[0047]Using fresh whole plant periwinkle (including root) as raw material, prepare vinblastine tartrate according to the following method:

[0048] 1. Extraction and preparation of crude vinblastine:

[0049] (1) Take 100kg of the whole periwinkle plant, add it to 850kg of 5wt% sodium chloride aqueous solution, soak it in ultrasonic for 15 minutes, then take out the periwinkle and put it directly into the cold air with a flow rate of 6.5m / s at -20°C for 40 minutes to freeze-dry. The periwinkle was crushed after freeze-drying.

[0050] (2) Add the periwinkle treated in step (1) to 300kg of water, adjust the pH to 1.5 with phosphoric acid, soak in ultrasonic for 3 hours, filter to get the filtrate, adjust the pH of the filtrate to 8-9 with ammonia water, after adjusting the pH, put the filtrate Apply high pressure and spray it from the top of the extraction tank in the form of a spray at a speed of 180 ml / s. At the same time, apply high pressure to the extractant and spray it i...

Embodiment 2

[0059] 1. Extraction and preparation of crude vinblastine:

[0060] Extract the crude vinblastine according to the method of Example 1, the difference is: the volume ratio of the filtrate to the extractant in step (2) is 5.5:1, and the extractant is n-bromopropane and ethanol with a volume ratio of 10:0.5 The mixture; in step (4), the volume ratio of dichloromethane and ethyl acetate is 10:3, and the volume ratio of toluene and petroleum ether is 8:1. The mass of the obtained crude vinblastine was 43.2 g, the yield was 0.432‰, and the purity by HPLC was 73.6%.

[0061] 2. Preliminary salt formation of vinblastine:

[0062] 43.2g of crude vinblastine was completely dissolved in 54.5ml of anhydrous methanol to form A solution. 14.1g of tartaric acid was completely dissolved by heating with 54.5ml of anhydrous methanol to form B solution. Slowly add solution B to solution A at 45-50°C, stir evenly after adding, and ultrasonicate at room temperature for 5 minutes. After crystal...

Embodiment 3

[0066] Vinblastine tartrate is prepared according to the method of Example 1, the difference is: when vinblastine tartrate is refined, 50.5g of vinblastine tartrate is added to 202ml of N,N-dimethylformamide solution and heated and stirred until Completely dissolve, then slowly add 202ml of a mixture of anhydrous methanol and ethyl acetate (anhydrous methanol: ethyl acetate volume ratio = 95:5) into the vinblastine tartrate solution, ultrasonicate for 5 minutes, and wait for crystals to form Afterwards, let stand at -18°C for 24 hours, and crystallize. The obtained crystals were suction-filtered at -18°C and freeze-dried at -20°C to obtain 44.8 g of high-purity vinblastine tartrate. The purity was 99.5% by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com