Self-cleaning solar paint and preparation method thereof

A solar energy and self-cleaning technology, which is applied in the field of solar energy materials, can solve the problems of large contact angle of the coating, difficulty in cleaning, and not obvious self-cleaning effect, and achieve good hydrophilic performance and improve power generation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

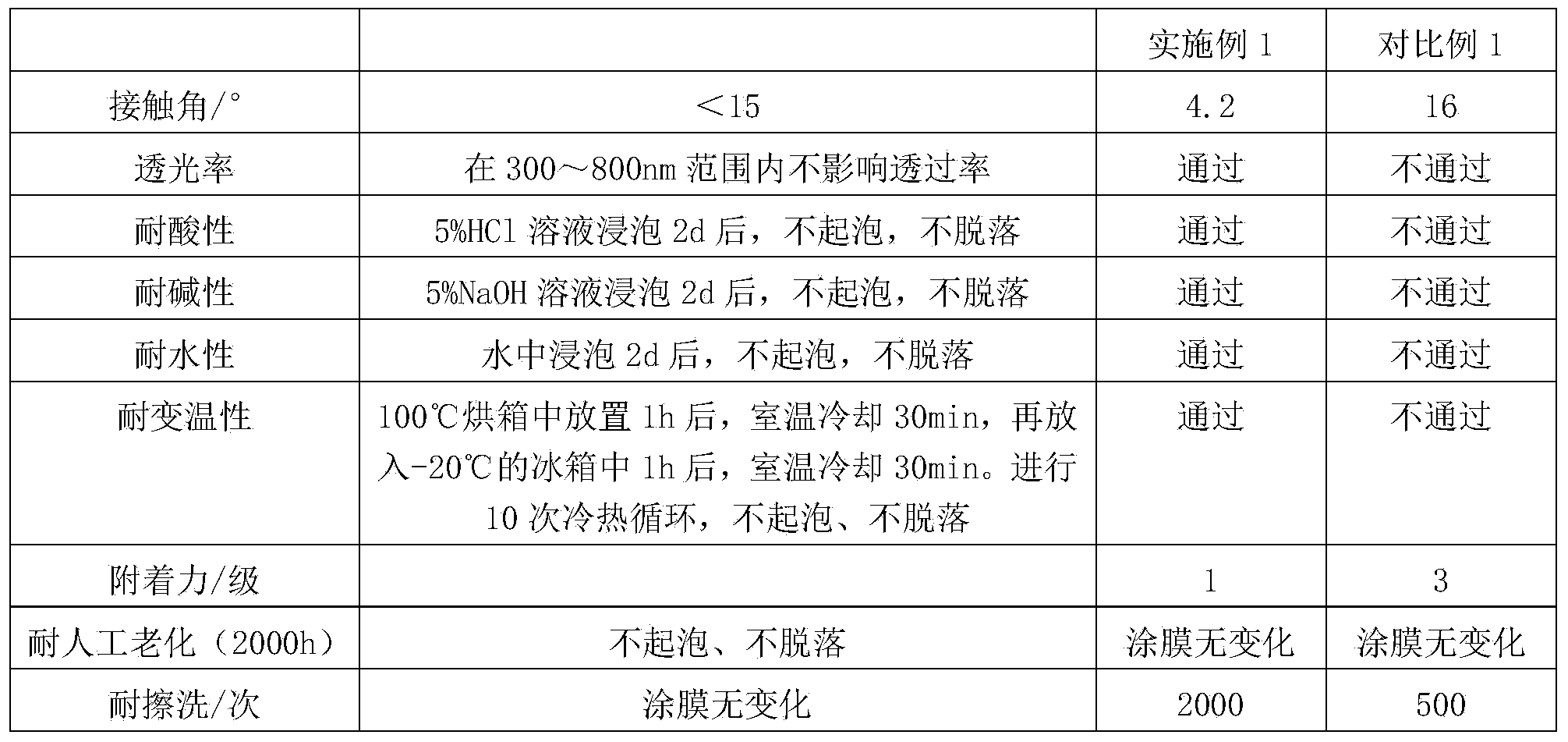

Examples

Embodiment 1

[0020] A kind of self-cleaning solar energy paint, raw material comprises by weight: 3 parts of epoxy acrylate, 1 part of polyurethane acrylate, 2 parts of benzophenone, 3 parts of 2-isopropyl thioxanthone, 2,4- 2 parts of ethyl dimethyl benzoate, 4 parts of 1,6-hexanediol diacrylate, 1 part of ethyl silicate, 2 parts of fatty acyldiethanolamine, 3 parts of tributyl phosphate, 1 part of cellulose acetate butyrate 2 parts, xylenol phosphate, 1 part dimethylaminoethyl acrylate, 3 parts filler, 2 parts pigment, 12 parts deionized water.

[0021] The above epoxy acrylate is bisphenol A type epoxy acrylate; the pigment is zinc oxide; the filler is calcium carbonate.

[0022] The preparation method of above-mentioned self-cleaning solar energy paint, comprises the following steps:

[0023] Step 1, add epoxy acrylate, urethane acrylate, benzophenone and dimethylaminoethyl acrylate to deionized water, program temperature rise (10°C every half hour) to 70°C, stir well, let cool After...

Embodiment 2

[0028] A kind of self-cleaning solar energy paint, raw material comprises by weight: 6 parts of epoxy acrylate, 3 parts of polyurethane acrylate, 4 parts of benzophenone, 5 parts of 2-isopropyl thioxanthone, 2,4- 4 parts of ethyl dimethyl benzoate, 5 parts of 1,6-hexanediol diacrylate, 3 parts of ethyl silicate, 3 parts of fatty acyldiethanolamine, 5 parts of tributyl phosphate, 3 parts of cellulose acetate butyrate 4 parts, 4 parts of xylenol phosphate, 3 parts of dimethylaminoethyl acrylate, 5 parts of filler, 4 parts of pigment, 16 parts of deionized water.

[0029] The above epoxy acrylate is bisphenol A type epoxy acrylate; the pigment is acidic barium metaborate; the filler is china clay.

[0030] The preparation method of above-mentioned self-cleaning solar energy paint, comprises the following steps:

[0031] Step 1, add epoxy acrylate, urethane acrylate, benzophenone and dimethylaminoethyl acrylate to deionized water, program temperature rise (10°C every half hour) t...

Embodiment 3

[0036] A kind of self-cleaning solar energy paint, raw material comprises by weight: 7 parts of epoxy acrylate, 5 parts of polyurethane acrylate, 6 parts of benzophenone, 7 parts of 2-isopropyl thioxanthone, 2,4- 8 parts of ethyl dimethyl benzoate, 6 parts of 1,6-hexanediol diacrylate, 5 parts of ethyl silicate, 4 parts of fatty acyldiethanolamine, 7 parts of tributyl phosphate, 6 parts of cellulose acetate butyrate 5 parts, 5 parts of xylenol phosphate, 4 parts of dimethylaminoethyl acrylate, 8 parts of filler, 5 parts of pigment, 19 parts of deionized water.

[0037] The above epoxy acrylate is bisphenol A type epoxy acrylate; the pigment is barium sulfate; the filler is mica powder.

[0038] The preparation method of above-mentioned self-cleaning solar energy paint, comprises the following steps:

[0039] Step 1, add epoxy acrylate, urethane acrylate, benzophenone and dimethylaminoethyl acrylate to deionized water, program temperature rise (10°C every half hour) to 70°C, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com