High-transparent flexible hollow metal nanofiber membrane and manufacturing method thereof

A metal nano and metal fiber technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of high electrical conductivity, high optical transparency, restricting the preparation of inorganic hollow nanostructured materials, etc., and achieve high electrical conductivity , high optical transparency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Step 1: preparation of polymer nanofiber membrane substrate;

[0057] Under normal temperature, the polyvinyl acetate (PVAc) of 0.7g is dissolved in the first solvent of 9.3g, mix uniformly and form the electrospinning solution of 10g; The first solvent is ethanol and DMF mixed solution, wherein ethanol and DMF The mass ratio of (N,N-dimethylformamide) is 1:2.

[0058] The electrospinning solution is directly sprayed onto the aluminum foil through the electrospinning equipment to form the substrate of the polyvinyl acetate nanofiber film; the operating voltage of the electrospinning equipment is 30KV, and the distance from the injection port to the aluminum foil (ie the substrate) is 30cm , the feed rate was 0.3ml / h, and the electrospinning time was 30min.

[0059] In this embodiment, the electrospinning equipment is selected from the SD series electrostatic nanospinning equipment of Japan MECC Company.

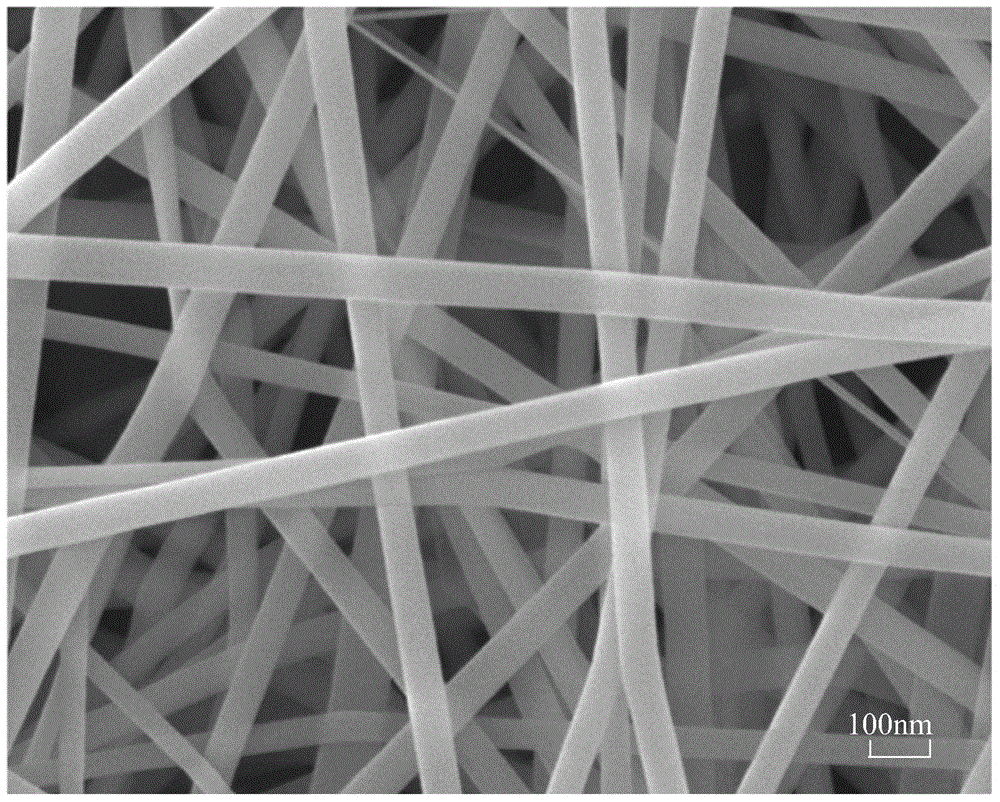

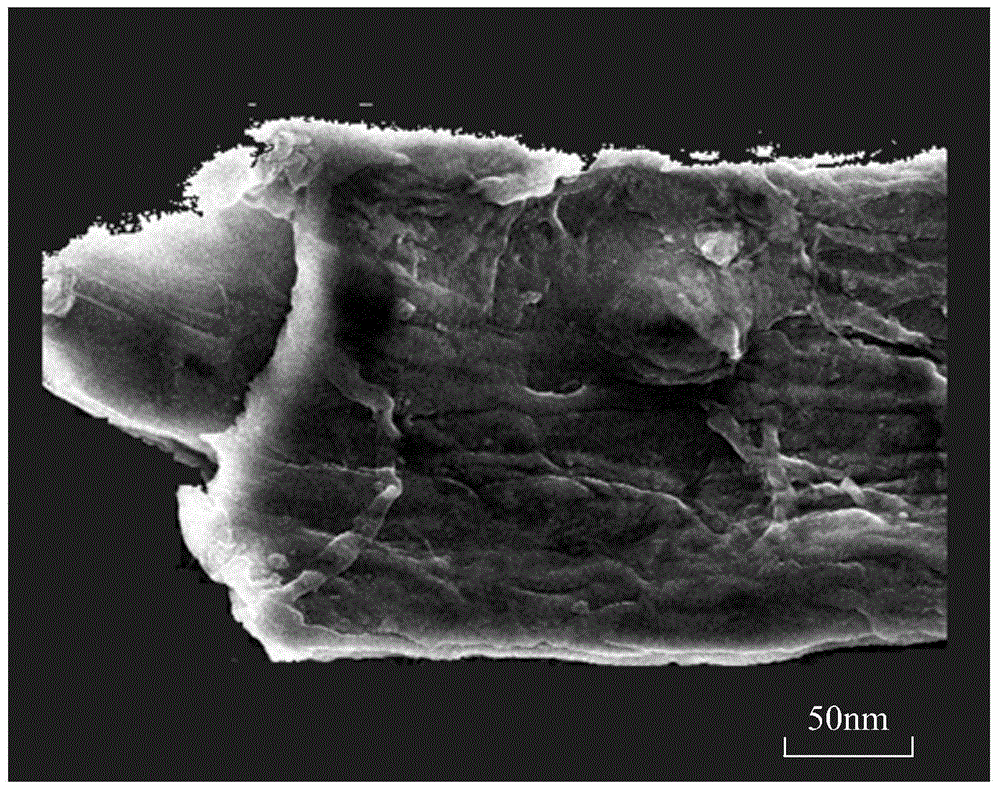

[0060] The morphology of the prepared polyvinyl acetate nanofib...

Embodiment 2

[0072] Step 1: preparation of polymer nanofiber membrane substrate;

[0073] At room temperature, 0.8 g of polyvinyl alcohol (PVA) was mixed with 9.2 g of deionized water, and then heated to 80° C. and stirred continuously to form an electrospinning precursor solution with a certain viscosity. The electrospinning precursor solution is directly sprayed onto the aluminum foil through the electrospinning equipment, wherein the operating voltage of the electrospinning equipment is 20KV, the distance from the injection port to the substrate is 20cm, and the feed rate of the electrospinning is 0.1ml / h, the electrospinning time of the electrospinning is 20min to form a polyvinyl alcohol nanofiber membrane.

[0074] Step 2: preparation of composite fiber membrane;

[0075] At room temperature, 2.0g of aluminum trichloride AlCl 3 Mix it with 0.4 g of polyvinyl butyral (PVB) in 7.6 g of ethanol and keep stirring to prepare a 20 wt % ethanol solution of aluminum trichloride. The etha...

Embodiment 3

[0082] Step 1: preparation of polymer nanofiber membrane substrate;

[0083] At room temperature, 1.0 g of polyvinylidene fluoride (PVDF) was mixed with 9 g of ethanol and DMF, wherein the mass ratio of ethanol and DMF was 1:3, and stirred continuously to form an electrospinning precursor solution with a certain viscosity. The electrospinning precursor solution is directly sprayed onto the copper wire net through the electrospinning equipment, wherein the operating voltage of the electrospinning equipment is 25KV, the distance from the injection port to the substrate is 25cm, and the feed rate of the electrospinning is 0.2 ml / h, the electrospinning time of the electrospinning is 10min, and a polyvinylidene fluoride nanofiber membrane is formed.

[0084] Step 2: preparation of composite fiber membrane;

[0085] At room temperature, 1.0 g of chloroauric acid and 0.3 g of polyethylene oxide (PEO) were mixed in 8.7 g of deionized water, and kept stirring to prepare an aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com