Laser-induced double-chamber micropump and fluid micropump drive method thereof

A technology of laser induction and driving method, which is applied in the field of control, micro fluid drive and supply, can solve the problems of limited service life of the pump membrane, low requirements for conveying fluid, and difficult size, so as to achieve no electromagnetic interference, simple introduction and transportation, The process is fast and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in detail below.

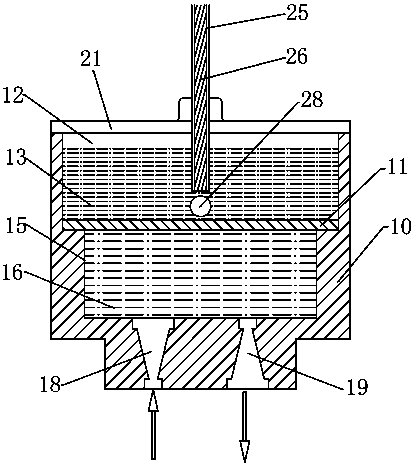

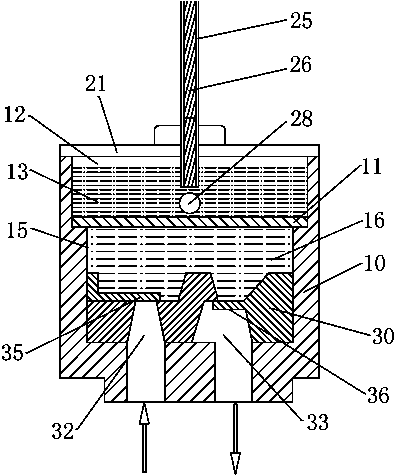

[0031] refer to figure 1 , figure 2 as shown, figure 1 demonstrated a laser-induced dual-cavity valveless micropump, figure 2 A laser-induced dual-chamber valved micropump is demonstrated. The present invention is a laser-induced double-cavity micropump, which includes a pump body 10 with an inner cavity, an elastic pump membrane 11 that is connected to the pump body 10 and separates the inner cavity into a driving cavity 12 and a pump cavity 15, and is inserted and filled with a driving liquid. The optical fiber 25 inside the driving chamber 12 of 13 is set on the pump body 10 and communicates with the pump chamber 15 to control the one-way flow control device for fluid to enter the pump chamber 15 and flow out of the pump chamber 15 in one direction. The one-way flow control device is a control structure that enables the fluid 16 to flow in one direction and is also called a directional flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com