Adsorbent for adsorbing mercury in smoke and preparation method of adsorbent

An adsorbent and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as small investment, high operating costs, and complex post-treatment of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

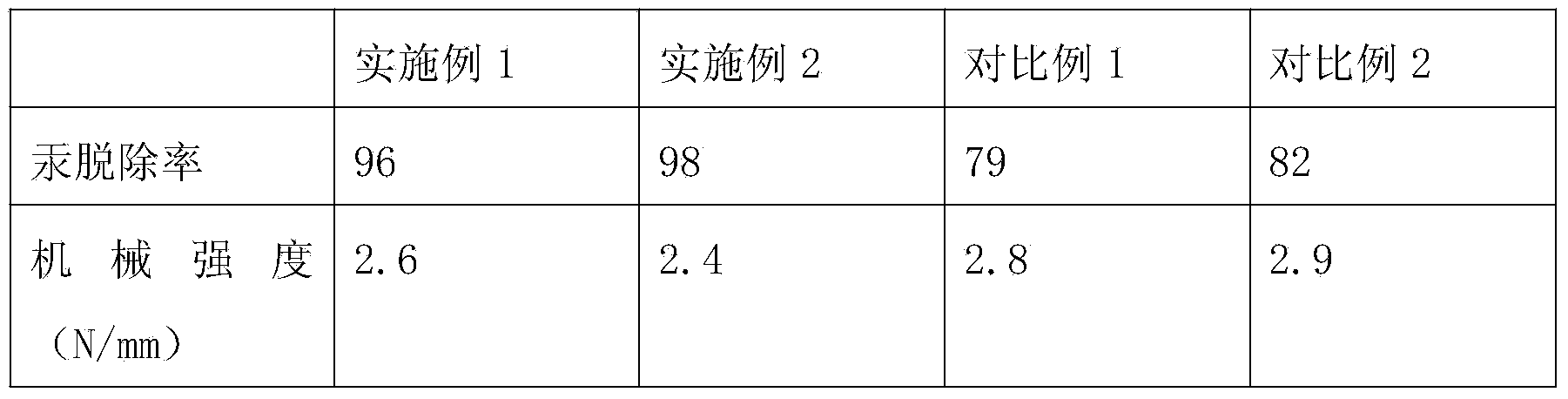

Examples

Embodiment 1

[0022] The adsorbent is composed of 200g of semi-coke powder, 100g of ferric chloride, 150g of copper oxide, 500g of aluminum oxide, and 30g of titanium dioxide. An aqueous solution with a concentration of 4mol / L, semi-coke powder is immersed in ferric chloride solution for 15h; b) Pseudoboehmite, titanium dioxide precursor, and copper oxide precursor are beaten and mixed according to the number of parts by mass; c) Then The semi-coke particles obtained in step a) are fully mixed with the slurry obtained in step b), and then formed and dried; d) the dried particles are calcined at 300° C. for 10 hours, and the adsorbent is obtained after cooling.

Embodiment 2

[0024] The adsorbent is composed of 250g of semi-coke powder, 80g of ferric chloride, 2000g of copper oxide, 600g of aluminum oxide, and 5g of titanium dioxide. An aqueous solution with a concentration of 4mol / L, semi-coke powder is immersed in ferric chloride solution for 15h; b) Pseudoboehmite, titanium dioxide precursor, and copper oxide precursor are beaten and mixed according to the number of parts by mass; c) Then The semi-coke particles obtained in step a) are fully mixed with the slurry obtained in step b), and then formed and dried; d) the dried particles are calcined at 500° C. for 15 hours, and the adsorbent is obtained after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com