Method for preparing nanometer titanium dioxide microcrystalline by utilizing solid state feeding manner

A technology of nano-titanium dioxide and titanium dioxide, which is applied in the field of chemical technology and new material synthesis, can solve problems such as complex process and equipment corrosion, and achieve the effects of short process flow, improved performance, and continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

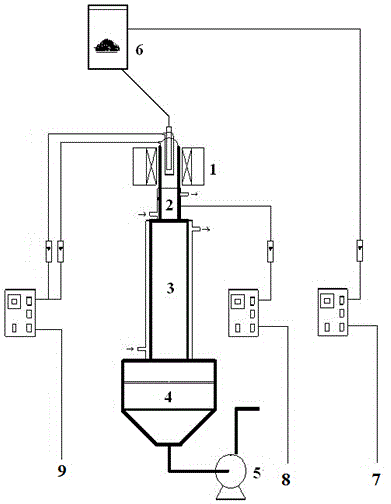

Method used

Image

Examples

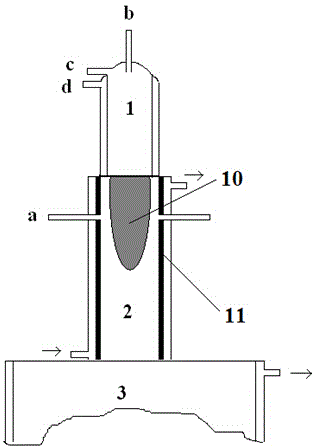

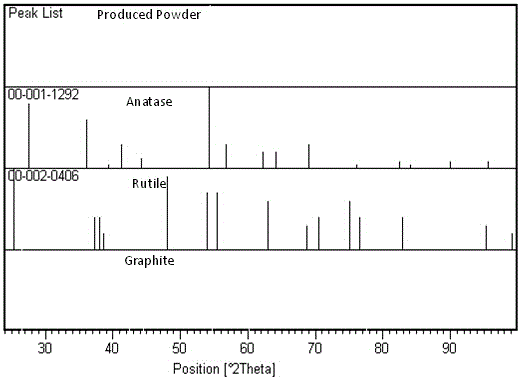

Embodiment approach 1

[0028]Titanium dioxide powder with an average particle size of 1.0 μm is used as raw material. Add 20g of titanium dioxide powder raw material to the solid feeder 6; the power of the high-frequency plasma generator 1 is 2.5KW; the inner diameter of the high-frequency plasma reactor 2 is 20mm, and the ratio of the length to the inner diameter is 4:1; the cooler 3 The inner diameter of the tube is 75mm, and the ratio of the length to the inner diameter is 4:1; the glass fiber in the product collector 4 is 150 mesh, and the power of the induced draft fan 5 is 200W. The cooling water flow rates of the high-frequency plasma reactor 2 and the cooler 3 are 20 l / h and 100 l / h respectively; with argon as the plasma working gas, the volume flow rates of gas and cooling gas at inlets c and d are respectively 3 l / min and 10 l / min; the air inlet a is located at 1 / 2 of the axial direction of the high-frequency plasma reactor 2, with a diameter of 0.5mm; the volume flow rate of oxygen at the...

Embodiment approach 2

[0030] Titanium dioxide powder with an average particle size of 1.0 μm is used as raw material. Add 30g of titanium dioxide powder raw material to the solid feeder 6; the power of the high-frequency plasma generator 1 is 3.0KW; the inner diameter of the high-frequency plasma reactor 2 is 25mm, and the ratio of the length to the inner diameter is 4:1; the cooler 3 The inner diameter of the tube is 150mm, and the ratio of the length to the inner diameter is 5:1; the glass fiber in the product collector 4 is 100 mesh, and the power of the induced draft fan 5 is 280W. The cooling water flows of the high-frequency plasma reactor 2 and the cooler 3 are 25 l / h and 150 l / h respectively; with argon as the plasma working gas, the volume flow rates of gas and cooling gas at inlets c and d are respectively 5 l / min and 15 l / min; the air inlet a is located at 1 / 2 of the axial direction of the high-frequency plasma reactor 2, with a diameter of 0.5 mm; the volume flow rate of oxygen in the a...

Embodiment approach 3

[0032] Titanium dioxide powder with an average particle size of 10 μm is used as raw material. Add 150g of titanium dioxide powder raw material to the solid feeder 6; the power of the high-frequency plasma generator 1 is 10KW; the inner diameter of the high-frequency plasma reactor 2 is 40mm, and the ratio of the length to the inner diameter is 5:1; The inner diameter is 150mm, and the ratio of the length to the inner diameter is 6:1; the glass fiber in the product collector 4 is 100 mesh, and the power of the induced draft fan 5 is 1000W. The cooling water flow rates of high frequency plasma reactor 2 and cooler 3 are 75 l / h and 500 l / h respectively; the mixture of argon and oxygen is used as the plasma working gas, the ratio of argon and oxygen is 5:1, gas and The volume flow rate of the cooling gas at the inlet c and d is 20 l / min and 60 l / min respectively; the inlet a is located at 2 / 3 of the axial direction of the high-frequency plasma reactor 2, and the diameter is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com