Novel buffer layer zinc oxide-sulfur target material and preparation method thereof

A technology of zinc oxide sulfur and buffer layer, applied in coating, superimposed layer plating, metal material coating process, etc., can solve the problems of difficult to manufacture in large size, high investment cost, low density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

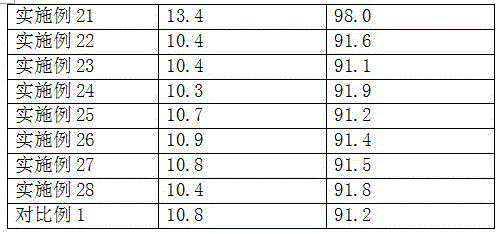

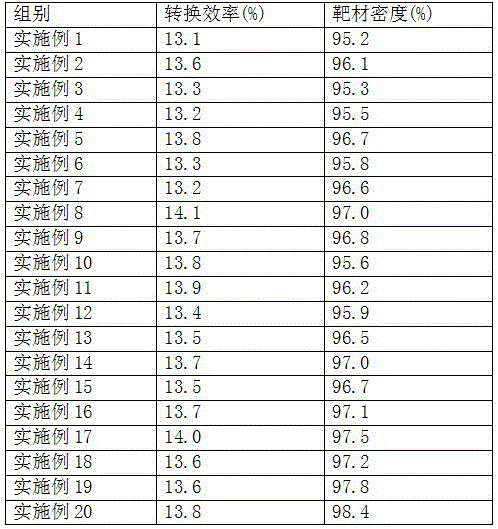

Examples

Embodiment 1

[0016] A method for preparing a new type of buffer layer zinc oxide sulfur target material, adding 10.0wt% zinc sulfide to zinc oxide to form a powder material, and then fully mixing with zirconia balls, pure water, and dispersant grinding, the mass ratio is: powder material : Zirconia balls: pure water: dispersant = 0.8:2.5:0.20:0.005; grind for 4 hours to form a slurry, then pour the slurry into a porous mold, after 12 hours of drying, release the film to form a multi-component oxidation The theoretical density of compound and sulfide mixture is 5.0g / cm 3 Then, after sintering at 800°C and 3 hours, a high-density target body for sputtering is formed, which is cut and surface ground into a target for vacuum magnetron sputtering, and the target is measured by the Archimedes method Density: with glass as the base material, put it into the vacuum magnetron sputtering machine, firstly, the vacuum pumping system will pump the background pressure of the sputtering chamber to 0.7×10...

Embodiment 2

[0019] A method for preparing a new type of buffer layer zinc oxide sulfur target material, adding 25.0wt% zinc sulfide to zinc oxide to form a powder material, and then fully mixing with zirconia balls, pure water, and dispersant grinding, the mass ratio is: powder material : Zirconia Ball: Pure Water: Dispersant=1.0:3.0:0.25:0.005; Grind for 14 hours to form a slurry, then pour the slurry into a porous mold, after 24 hours of drying, release the film to form a multi-component oxidation The theoretical density of compound and sulfide mixture is 5.1 g / cm 3 Then, after sintering at 1000°C and 5 hours, a high-density target body for sputtering is formed, which is cut and surface ground into a target for vacuum magnetron sputtering, and the target is measured by the Archimedes method Density: with glass as the base material, put it into the vacuum magnetron sputtering machine, firstly, the vacuum pumping system will pump the background pressure of the sputtering chamber to 0.8×10...

Embodiment 3

[0022] A method for preparing a new type of buffer layer zinc oxide sulfur target material, adding 45.0wt% zinc sulfide to zinc oxide to form a powder material, and then fully mixing with zirconia balls, pure water, and dispersant grinding, the mass ratio of which is: powder material : Zirconia balls: pure water: dispersant = 1.2:3.5:0.30:0.005; after grinding for 24 hours to form a slurry, then pour the slurry into a porous mold, after 36 hours of drying, the film is released to form a multi-component oxidation The theoretical density of compound and sulfide mixture is 5.2 g / cm 3 Then, after sintering at 1200°C and 24 hours, a high-density target body for sputtering is formed, which is cut and surface ground into a target for vacuum magnetron sputtering, and the target is measured by the Archimedes method Density: with glass as the base material, put it into the vacuum magnetron sputtering machine, firstly, the vacuum pumping system will pump the background pressure of the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com