3D printing method of lithium battery

A 3D printing, lithium battery technology, applied in the direction of lithium battery, battery electrode, non-aqueous electrolyte battery, etc., can solve the problems of open circuit, selection of positive and negative materials isolation printing method, lithium storage capacity attenuation, etc., to achieve high ionic and electronic Conductivity, novel preparation method, and the effect of shortening the diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

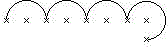

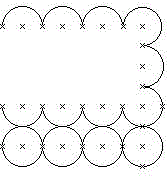

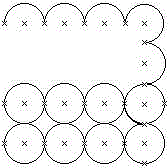

Method used

Image

Examples

Embodiment 1

[0039] 1) Take 4g of highly concentrated lithium titanate with a weight ratio of 57% and disperse it in 140ml of deionized water and 9g of sodium lauryl sulfate to form the first mixed solution; another 60% by weight of lithium iron phosphate 2g is dispersed in the sodium lauryl sulfate of 110ml deionized water and 9g to form the second mixed solution;

[0040] 2) Immerse the first mixed solution and the second mixed solution at room temperature for 40 hours, centrifuge at 4000rpm for 2 hours, the collected particles are controlled at a diameter of 170nm, and the collected particles are redispersed to a weight ratio of 10% Glycerin, 4% sodium carboxymethyl starch by weight, 3% polyvinylpyrrolidone homopolymer (PVP) by weight, and 3% sodium carboxymethylcellulose by weight, and ultrasonication for 2 hours, thereby Produce homogenate, denote respectively as the first slurry and the second slurry;

[0041] 3) The components of the prepared lithium titanate homogenate are 20% glyce...

Embodiment 2

[0058] 1) Take 4.5g of highly concentrated lithium titanate with a weight ratio of 57% and disperse it in 150ml of deionized water and 11g of sodium lauryl sulfate to form the first mixed solution; another iron phosphate with a weight ratio of 60% Lithium 3g is dispersed in the sodium lauryl sulfate of 120ml deionized water and 11g to form the second mixed solution;

[0059] 2) The first mixed solution and the second mixed solution were soaked at room temperature for 45 hours, centrifuged at 4000rpm for 2.5 hours, the collected particles were controlled at a diameter of 180nm, and the collected particles were redispersed to a weight ratio of 12%. Glycerin, 6% sodium carboxymethyl starch by weight, 4% polyvinylpyrrolidone homopolymer (PVP) by weight, 4% sodium carboxymethylcellulose by weight, and ultrasonication for 2.5 hours, Thereby produce homogenate, denote respectively as the first slurry and the second slurry;

[0060] 3) The components of the prepared lithium titanate ...

Embodiment 3

[0077] 1) Take 5g of highly concentrated lithium titanate with a weight ratio of 57% and disperse it in 160ml of deionized water and 14g of sodium lauryl sulfate to form the first mixed solution; another 60% by weight of lithium iron phosphate 4g is dispersed in the sodium lauryl sulfate of 130ml deionized water and 14g to form the second mixed solution;

[0078] 2) The first mixed solution and the second mixed solution were soaked at room temperature for 50 hours, centrifuged at 4000rpm for 3 hours, the collected particles were controlled at a diameter of 190nm, and the collected particles were redispersed to a weight ratio of 13% Glycerin, 8% sodium carboxymethyl starch by weight, 5% polyvinylpyrrolidone homopolymer (PVP) by weight, and 5% sodium carboxymethylcellulose by weight, and ultrasonication for 3 hours, thereby Produce homogenate, denote respectively as the first slurry and the second slurry;

[0079] 3) The components of the prepared lithium titanate homogenate ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com