Lithium manganate material and preparation method thereof and lithium ion battery cathode material

A technology of lithium manganese oxide and slurry, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of irregular shape, impure crystal, uneven mixing, etc., achieve good conductivity, excellent cycle, strengthen Effect of Mix Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention proposes a preparation method of lithium manganate material, comprising the following steps (such as Figure 5 ):

[0032] Step 1: Add the lithium source, manganese source, doped metal oxygen compound, and flux to the ball mill (this application ball mill uses the QHJM-100 model produced by Changsha Qinghe General Machinery Equipment Co., Ltd.), and add The solvent is ball milled in a ball mill to make the slurry particle size below 1 μm;

[0033] Step 2: Transfer the slurry obtained in step 1 to a sand mill (the sand mill used in this application uses the KLZr-3B model produced by Shenzhen Keli Nano Engineering Equipment Co., Ltd.) for crushing, and add Dispersant, which stabilizes the components of the suspension and makes the particle size of the slurry reach 200nm to 300nm;

[0034] Step 3: transfer the slurry obtained in step 2 into a centrifugal spray drying tower (the spray drying tower of this application adopts the BG-10 model produced b...

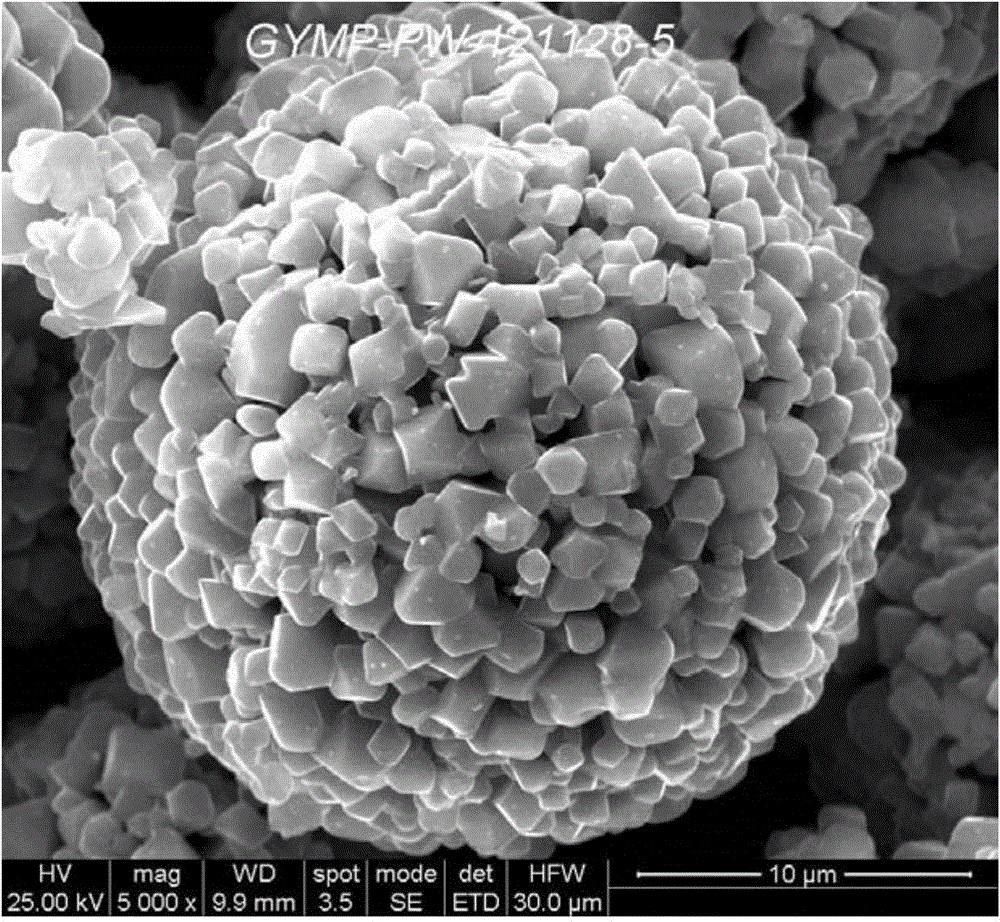

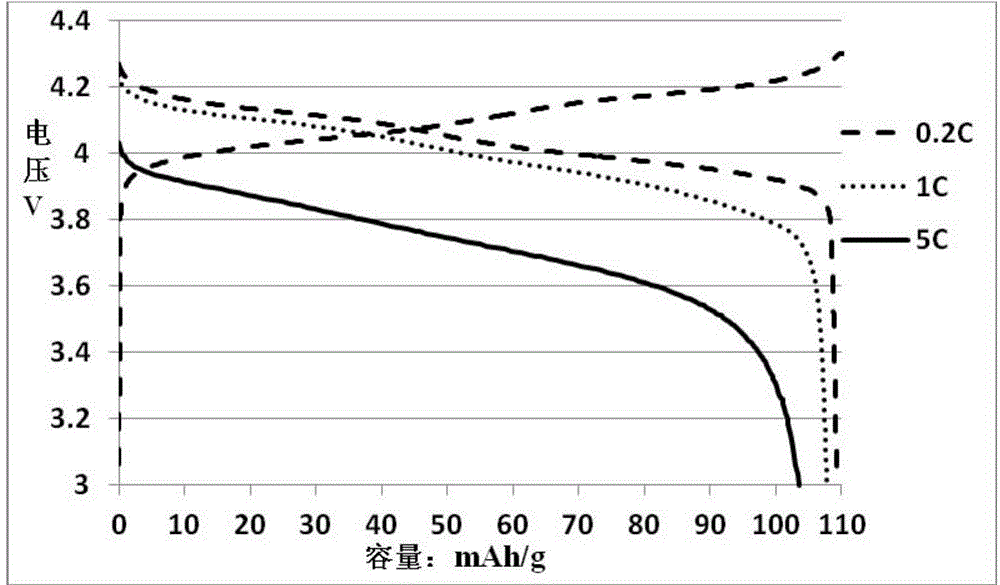

Embodiment 1

[0055] Lithium carbonate, manganese dioxide, magnesium oxide, and aluminum oxide totaled 10kg according to the molar ratio Li:Mn:Mg:Al=1.04:1:0.01:0.02, and weighed 50g of boron trioxide and 500g of polyethylene glycol Add 20000 to the 100L circulating stirring ball mill tank machine at the same time, and add 30Kg deionized water to the ball mill tank for stirring ball milling. The stirring frequency is 30Hz, and the circulating pneumatic diaphragm pump is turned on to increase the uniformity of the mixture. After about 3 hours of ball milling, the slurry is taken Conduct particle size test D 50 When the thickness is less than 1 μm, stop the ball mill and put the slurry into a sand mill.

[0056] Start the horizontal sand mill for further particle refinement and mixing. The speed frequency of the sand mill is controlled at 1300Hz, and the particle size D after sanding for about 5 hours 50 When it is reduced to between 200nm and 300nm, the fine crushing is completed. Pour th...

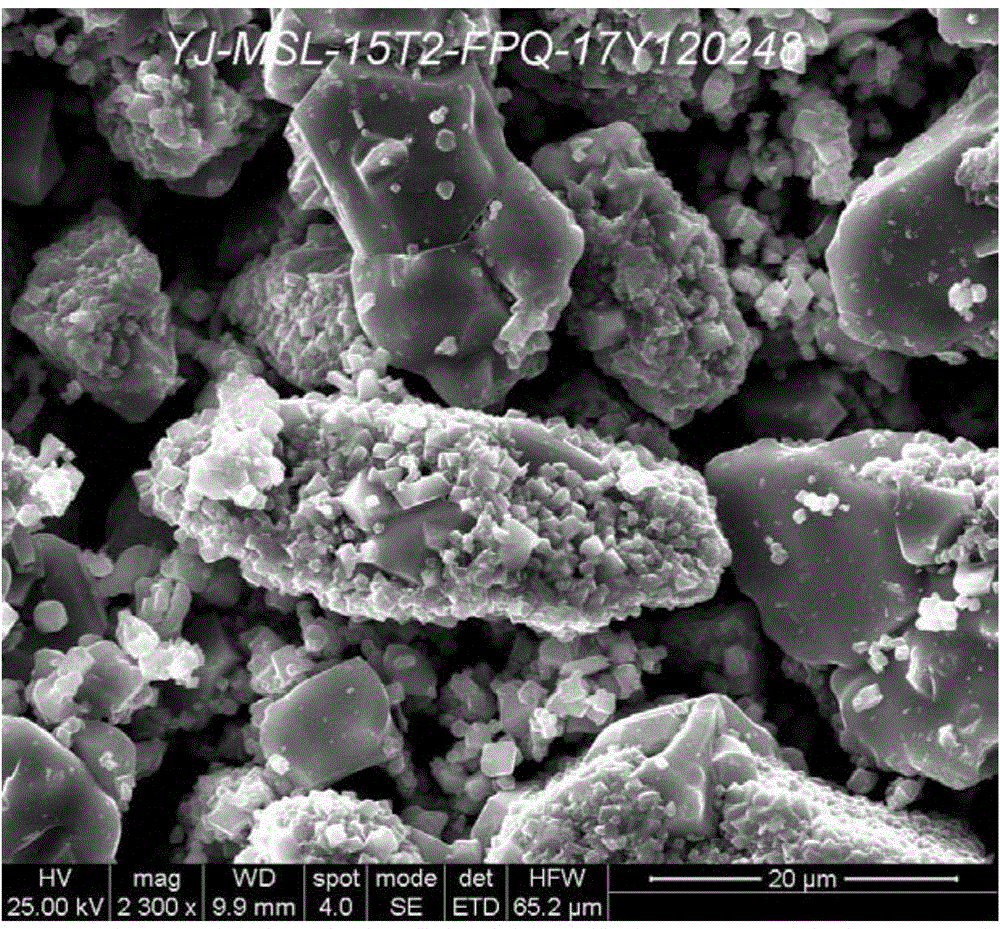

Embodiment 2

[0060] Lithium carbonate, manganese dioxide, magnesium oxide, and aluminum oxide totaled 10kg according to the molar ratio Li:Mn:Mg:Al=1.01:1:0.05:0.01, and weighed 10g of boron trioxide and 500g of polyethylene glycol Add 20000 to the 100L circulating stirring ball mill at the same time, add 30Kg deionized water to the ball milling tank for stirring ball milling, the stirring frequency is 30Hz, and turn on the circulating pneumatic diaphragm pump to increase the uniformity of the mixture. After about 3h ball milling, take the slurry for Particle size test D 50 When the thickness is less than 1 μm, stop the ball mill and put the slurry into a sand mill.

[0061] Start the horizontal sand mill for further particle refinement and mixing. The speed frequency of the sand mill is controlled at 1200Hz, and the particle size is D 50 Fine crushing is completed when reduced to 300nm. Pour the slurry into a spray drying container jar ready for spraying.

[0062] Spray drying adjusts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com