Carbon doped nano tube aerogel and preparation method and application thereof

A carbon nanotube and aerogel technology, applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., to achieve the effect of strengthening the cross-linking force of the system, reducing the cost and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (1) Take 8 mL of the aqueous dispersion of oxidized multi-walled carbon nanotubes with a concentration of 4 mg / mL, add 0.8 mL of pyrrole as an accelerator, mix the two evenly in a small beaker, put them in a hydrothermal kettle, and place them in water at 180 ° C. Thermal reaction for 20 hours to obtain carbon nanotube / pyrrole composite hydrogel;

[0076] (2) Wash the hydrogel with a large amount of water, and then use a large amount of ethanol to replace the water in the gel to obtain an ethanol gel of carbon nanotubes / pyrrole, dry it with supercritical carbon dioxide, and dry it for 9 hours to obtain a carbon nanotube / pyrrole ethanol gel. The nanotube / pyrrole airgel is then carbonized at 1030° C. for 3 hours under the protection of argon to obtain the nitrogen-doped carbon nanotube airgel provided by the present invention.

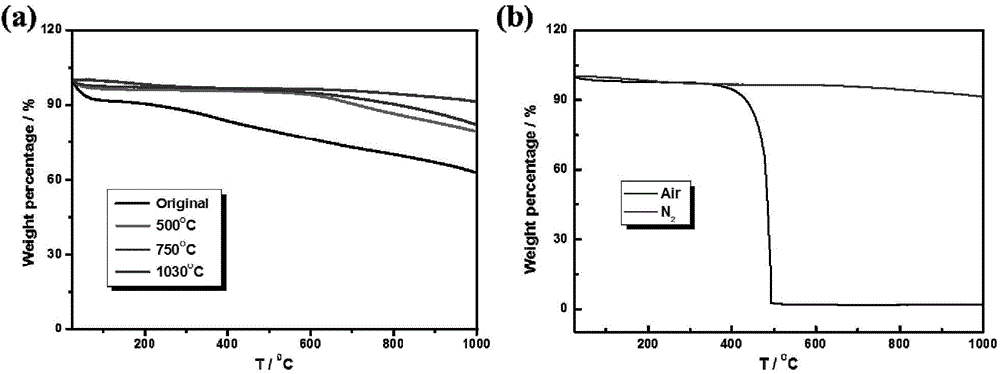

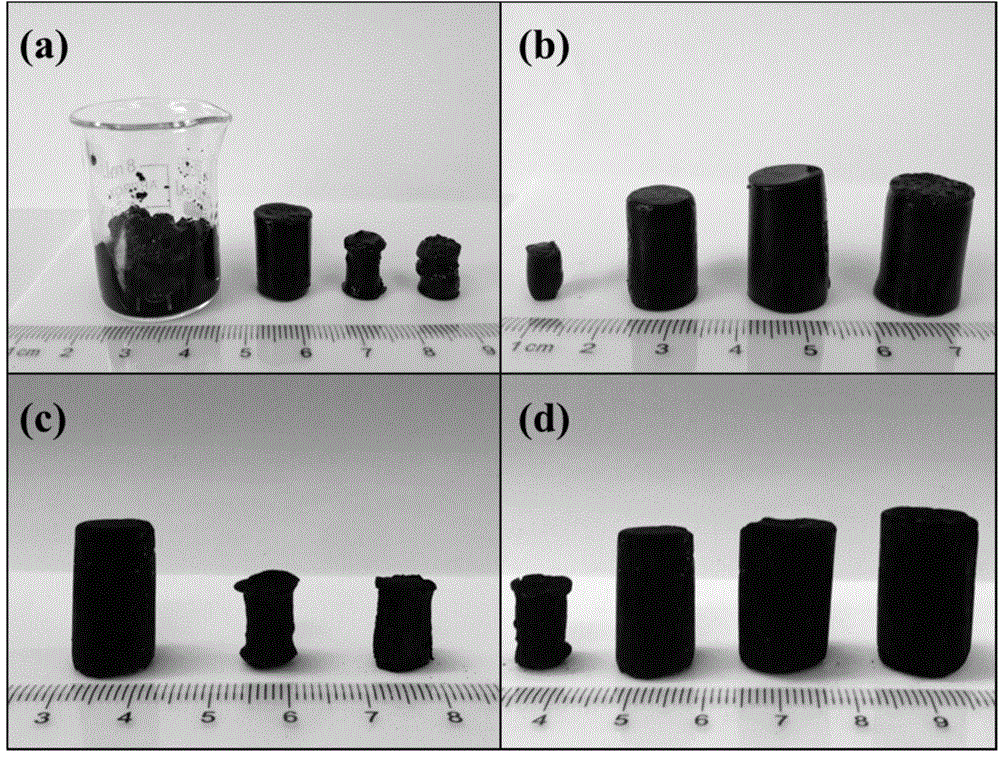

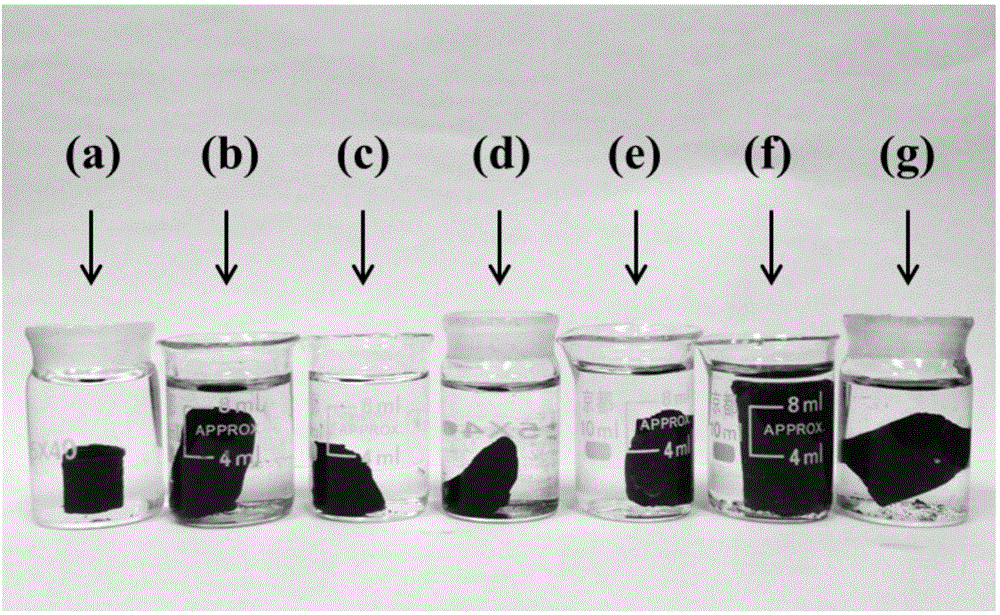

[0077] figure 1 It is a digital photo of the nitrogen-doped carbon nanotube airgel (promoter is pyrrole) obtained in this example and the airgel...

Embodiment 2

[0097] (1) Take 8 mL of oxidized multi-walled carbon nanotube solution with a concentration of 4 mg / mL, add 0.8 mL of pyrrole, mix the two evenly in a small beaker, put them in a hydrothermal kettle, and react at 180 ° C for 20 hours to obtain carbon Nanotube / pyrrole composite hydrogel;

[0098] (2) The hydrogel was washed with a large amount of water, and freeze-dried for 24 hours to obtain a carbon nanotube / pyrrole aerogel.

[0099] (4) The carbon nanotube / pyrrole aerogel was carbonized at 1030° C. for 3 h under the protection of argon to obtain the nitrogen-doped carbon nanotube aerogel.

Embodiment 3

[0101] (1) Take 8 mL of oxidized single-walled carbon nanotube solution with a concentration of 4.5 mg / mL, add 0.8 mL of aniline, mix the two evenly in a small beaker, put them in a hydrothermal kettle, and react at 180 ° C for 20 h to obtain Carbon nanotube / aniline composite hydrogel;

[0102] (2) The hydrogel is washed with a large amount of water, and then the water in the gel is replaced with a large amount of ethanol, thereby obtaining a carbon nanotube / aniline ethanol gel.

[0103] (3) Drying the carbon nanotube / aniline ethanol gel with supercritical carbon dioxide for 9 hours to obtain the carbon nanotube / aniline airgel.

[0104] (4) The carbon nanotube / aniline airgel was carbonized at 1030° C. for 3 h under the protection of argon to obtain the nitrogen-doped carbon nanotube airgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com