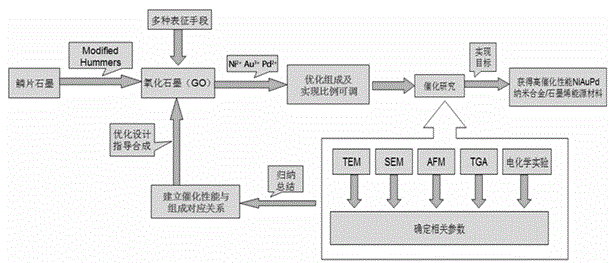

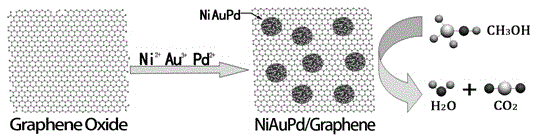

Preparation method and product of NiAuPd nano alloy/graphene high-efficiency catalyst

A nano-alloy and graphene technology is applied in the field of preparation of NiAuPd nano-alloy/graphene high-efficiency catalyst to achieve the effects of simple reduction conditions, high yield and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

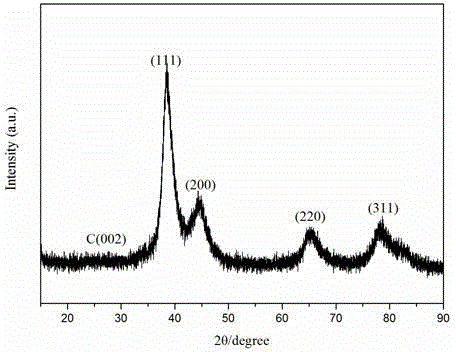

Embodiment 1

[0027]1) Graphene oxide was prepared by the Hummers method. The specific method is: add 1.0 g of dried flake graphite, 1.2 g of potassium nitrate, and 46 ml of concentrated sulfuric acid into a 250 ml four-necked flask, and mix them evenly under the action of ultrasound. , then stirred in an ice-water bath and slowly added 6.0 g of potassium permanganate. Subsequently, the temperature of the reaction system was raised to 40° C., and the reaction was stirred at high speed for 6 hours. Then, while slowly adding 80 milliliters of distilled water, the system was heated up to 70° C. and reacted for half an hour. Add 100 milliliters of distilled water and 6 milliliters of hydrogen peroxide (30% by mass) to the system, stop the reaction after 5 minutes, and obtain a bright yellow graphene oxide mother liquor. The obtained graphene oxide mother liquor is centrifuged at low speed to take the upper layer to remove unoxidized graphite; then centrifuged at high speed to take the lower la...

Embodiment 2

[0031] pH=9, other steps are with embodiment 1. The obtained NiAuPd nano-alloy / graphene high-efficiency catalyst alloy particles have an average particle size of 2.7 nm.

Embodiment 3

[0033] PH=10, other steps are with embodiment 1. The obtained NiAuPd nano-alloy / graphene high-efficiency catalyst alloy particles have an average particle size of 3.5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com