Method for preparing o-methoxybenzaldehyde by use of micro-reaction device

A technology of o-methoxybenzaldehyde and micro-reaction devices, which is applied to the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of complex processes and low yields, and achieve simple processes and relatively low yields. The effect of large surface area and high operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

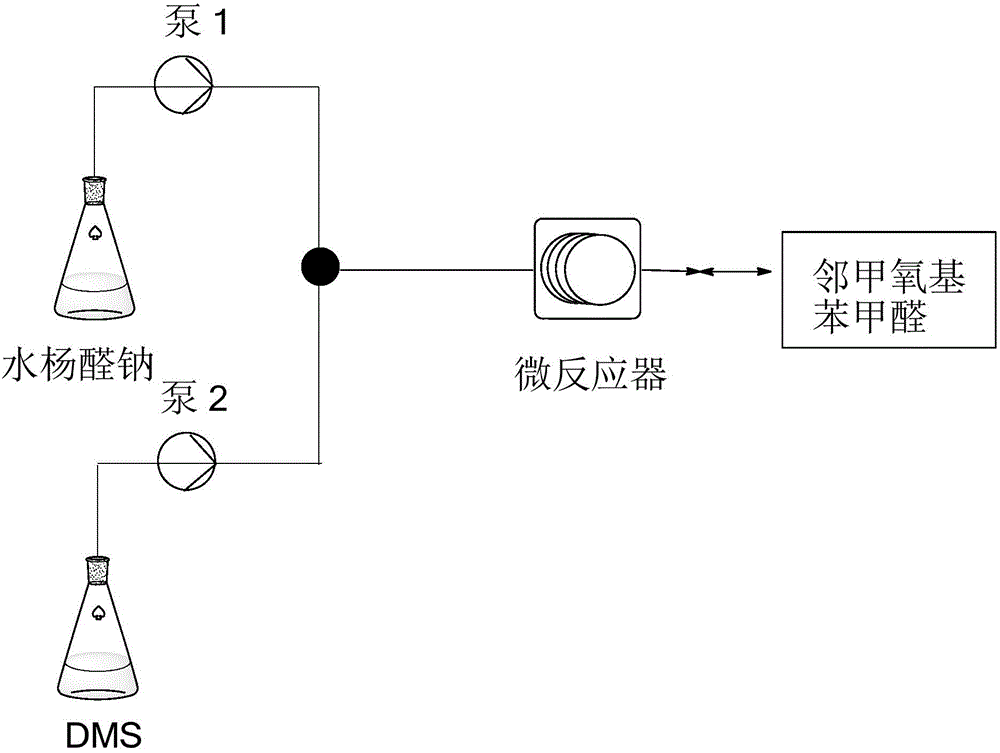

[0028] In the microchannel reaction device, the diameter of the connecting pipe is 0.8mm, the length of the liquid inlet pipe is 15cm, the length of the connecting pipe between the T-valve and the microchannel reactor is 32cm, and the length of the connecting pipe between the microreactor and the outlet is 32cm; the volume of the microchannel reactor is 5ml.

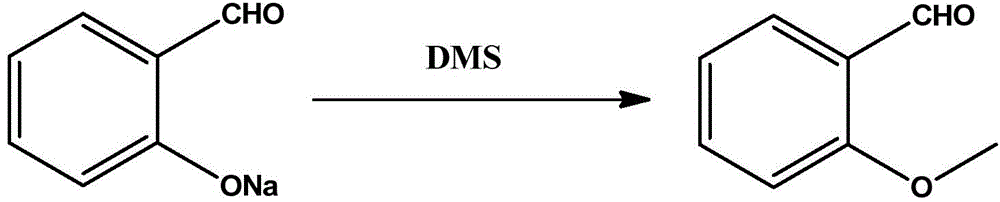

[0029] Take 0.025mol (3.05g) of salicylaldehyde, add it to an aqueous solution containing 0.025mol sodium hydroxide and stir to form a homogeneous phase, and the volume of the mixed solution is 30mL; weigh 0.025mol (3.15g) of dimethyl sulfate, add THF to dilute to 30mL . The two materials are mixed and pumped into the microchannel reactor through the T-valve. The two reaction fluids flowed through the microreactor at 2.5mL / min respectively, the reaction molar ratio of salicylaldehyde and dimethyl sulfate was 1:1.0, the reactor temperature was 110°C, the reaction residence time was 1min, and the crude oil was collected a...

Embodiment 2

[0031] In the microchannel reaction device, the diameter of the connecting pipe is 2.0mm, the length of the inlet pipe is 15cm, the length of the connecting pipe between the T-shaped valve and the microchannel reactor is 32cm, and the length of the connecting pipe between the microreactor and the outlet is 32cm; the volume of the microchannel reactor is 2ml.

[0032] Take 0.025mol (3.05g) of salicylaldehyde, add it to an aqueous solution containing 0.0275mol sodium hydroxide and stir to form a homogeneous phase, and the volume of the mixed solution is 30mL; weigh 0.0275mol (3.47g) of dimethyl sulfate, add DMF to dilute to 30mL . The two materials are mixed and pumped into the microchannel reactor through the T-valve. The two reaction fluids flow through the microreactor at 0.1mL / min respectively, the molar ratio of salicylaldehyde and dimethyl sulfate is 1:1.1, the temperature of the reactor is 90°C, the reaction residence time is 10min, and the crude product is collected at ...

Embodiment 3

[0034] In the microchannel reaction device, the diameter of the connecting pipe is 1.0mm, the length of the inlet pipe is 15cm, the length of the connecting pipe between the T-valve and the microchannel reactor is 32cm, and the length of the connecting pipe between the microreactor and the outlet is 32cm; the volume of the microchannel reactor is 10ml.

[0035] Take 0.05mol (6.05g) of salicylaldehyde, add it to the aqueous solution containing 0.0525mol sodium hydroxide and stir to form a homogeneous phase, and the volume of the mixed solution is 40mL; weigh 0.065mol (8.19g) of dimethyl sulfate, add dioxane Dilute to 40mL. The two materials are mixed and pumped into the microchannel reactor through the T-valve. Two kinds of reaction solution fluids flowed through the microreactor at 2.5mL / min respectively, the reaction molar ratio of salicylaldehyde and dimethyl sulfate was 1:1.3, the temperature of the reactor was 70°C, the reaction residence time was 2min, and the crude oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com