A kind of high-barrier TPU film for pipeline lining and preparation method thereof

A high-barrier, thin-film technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor dispersion, easy accumulation of GONRs, etc., and achieve the effects of good compatibility, improved penetration difficulty, and reduced solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

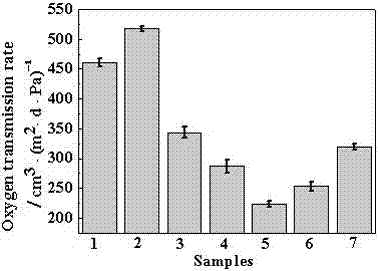

[0023] Slowly pour 15 g of pre-dried TPU particles into 80 mL of DMF solution, place it in a blast drying oven at 80 ° C for 1 h, and then stir the mixed system on a mechanical stirrer for 3.5 h until the TPU is completely dissolved. Place in a 100W ultrasonic cleaner for ultrasonic dispersion for 2 hours, then pour the mixed pasty liquid into a small volumetric flask with a straw, pump out the air in the pasty liquid on a suction filter and let it stand for 1.5 hours. Place the glass plate with a clean surface on the film coating machine to coat the film, and control the film thickness to 0.08mm. After the coating is completed, let the glass plate air at room temperature for 24 hours to fully evaporate the solvent and obtain a pure TPU material film.

Embodiment 2

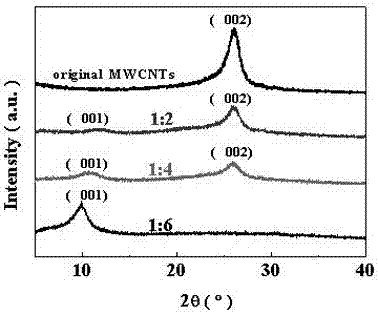

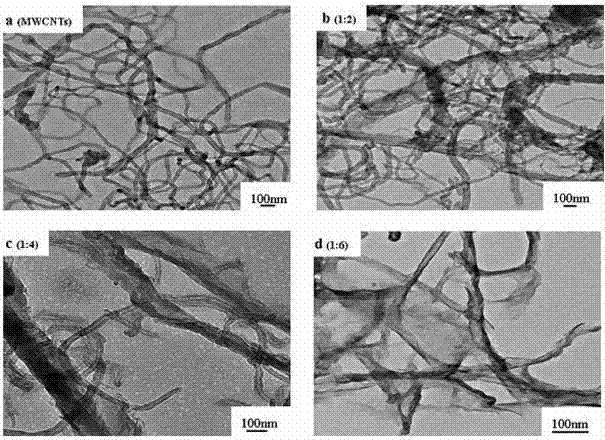

[0025] A high-barrier TPU film for pipeline lining, the preparation method of which is to adopt the oxidation longitudinal cutting MWCNTs method, by controlling the MWCNTs and KMnO in the reaction system 4 The mass ratio of graphene oxide nanoribbons-carbon nanotubes (GONRs-CNTs) nanocomposite composites with different content ratios was prepared, and then TPU resin was used as a matrix to prepare GONRs-CNTs / TPU composite film.

[0026] The diameter of the MWCNTs is 60 nm.

[0027] Its preparation method specifically comprises the following steps:

[0028] 1) Preparation of GONRs-CNTs nanocomposite complex: 180mL concentrated H with a mass fraction of 98% 2 SO 4 Pour into a 250mL round bottom flask, then slowly add 20mL of 85.5% H 3 PO 4 , Stir evenly at a speed of 100 r / min; then add 1g MWCNTs, stir for 1.5h, after the MWCNTs are evenly dispersed, slowly add 2g KMnO 4 (KMnO 4 The speed of adding is controlled at 1g / h), and stirred for 1h to obtain a mixed solution with ...

Embodiment 3

[0032] Step 1) KMnO 4 The addition amount of GONRs-CNTs / TPU composite material is 3g, and other condition parameters are the same as in Example 2, and finally 0.075g of GONRs-CNTs / TPU composite film with a content of 1:3 (marked as 1:3-TPU) is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com