High-breathability super-hydrophobic polyvinyl alcohol nanofiber non-woven fabric, and preparation method and applications thereof

A nanofiber, polyvinyl alcohol technology, applied in the direction of fiber type, fiber processing, separation method, etc., can solve the problems of inability to store and transport, difficult to find application fields, and inability to use, achieve moderate strength, heat shrinkage resistance, production Environmentally friendly process, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

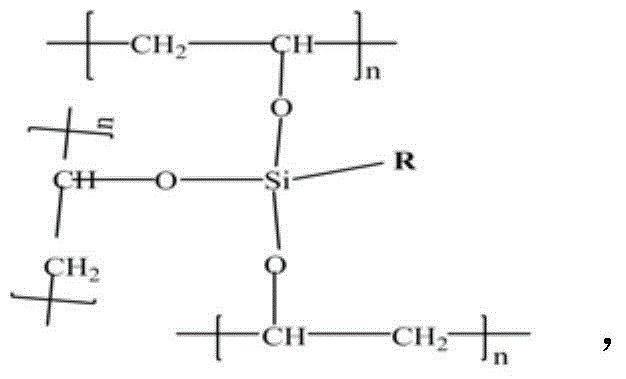

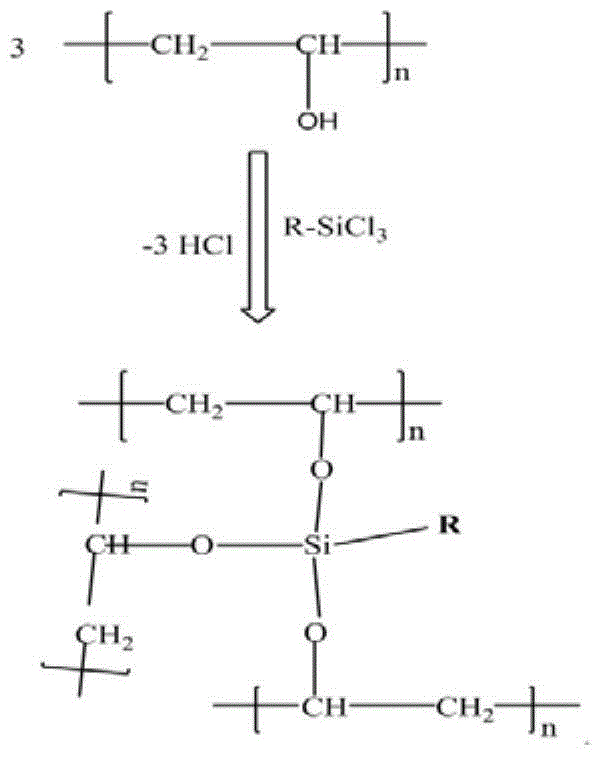

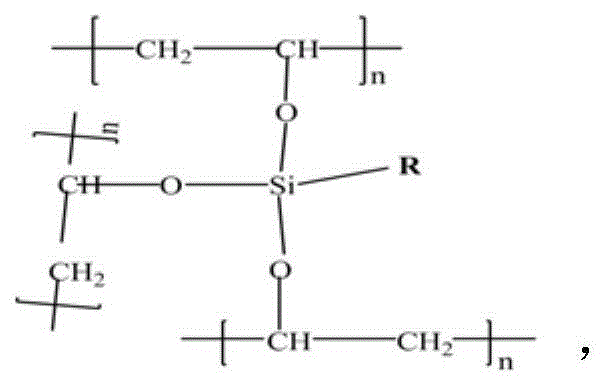

[0017] Embodiment 1: Preparation of PVA nanofiber nonwoven fabric modified by methyltrichlorosilane

[0018] (1) PVA electrospinning: Shanghai Ziyi Reagent Factory polyvinyl alcohol (average molecular weight Mw = 88000, intrinsic viscosity 1.20dL / g) 100g mixed with a mixed solvent composed of 700g distilled water and 200g absolute ethanol, and added 0.8g chloride Ammonium (in order to increase the conductivity of the solution), stirred and dissolved at 60° C. for 4 hours to form a transparent homogeneous solution with a mass concentration of 10%; the absolute viscosity of the solution is 1.8 Pa.s. The solution was electrospun in an electric field with an electric field strength of 250kV / m, and a stainless steel mesh belt with a width of 1 meter was used as a collector to collect polyamic acid nanofiber nonwovens, and the belt speed was 2.0m / min.

[0019] (2) Nanofiber surface hydrophobization treatment: dissolving the upper 15g methyltrichlorosilane in 985g cyclohexane to form...

Embodiment 2

[0021] Example 2: Preparation of Octadecyltrichlorosilane-modified PVA nanofiber nonwoven fabric

[0022] (1) PVA electrospinning: Shanghai Ziyi Reagent Factory polyvinyl alcohol (average molecular weight Mw=88000, intrinsic viscosity 1.20dL / g) 140g mixed with a mixed solvent composed of 530g distilled water and 330g absolute ethanol, and added 0.8g chlorinated Ammonium (in order to increase the conductivity of the solution), stirred and dissolved at 60° C. for 5 hours to form a transparent homogeneous solution with a mass concentration of 14%; the absolute viscosity of the solution was 3.0 Pa.s. The solution was electrospun in an electric field with an electric field strength of 200kV / m, and a stainless steel mesh belt with a width of 1 meter was used as a collector to collect polyamic acid nanofiber nonwovens, and the belt speed was 2.0m / min.

[0023] (2) Nanofiber surface hydrophobization treatment: dissolving the upper 15g octadecyl trichlorosilane in 985g sherwood oil to ...

Embodiment 3

[0025] Example 3: Preparation of PVA nanofiber nonwoven fabric modified by phenyltrichlorosilane

[0026] (1) PVA electrospinning: Shanghai Ziyi Reagent Factory polyvinyl alcohol (average molecular weight Mw=88000, intrinsic viscosity 1.20dL / g) 100g mixed with a mixed solvent composed of 550g distilled water and 350g absolute ethanol, and added 0.8g chloride Ammonium (in order to increase the conductivity of the solution), stirred and dissolved at 60° C. for 4 hours to form a transparent homogeneous solution with a mass concentration of 10%; the absolute viscosity of the solution was 2.0 Pa.s. The solution was electrospun in an electric field with an electric field strength of 250kV / m, and a stainless steel mesh belt with a width of 1 meter was used as a collector to collect polyamic acid nanofiber nonwovens, and the belt speed was 2.0m / min.

[0027] (2) Nanofiber surface hydrophobization treatment: dissolving the upper 15g phenyltrichlorosilane in 985g tetrahydrofuran to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com