Nitrogen-doped graphene carbon composite material and preparation method thereof

A nitrogen-doped graphene and composite material technology, applied in the field of material science, can solve the problems of low yield of freeze-drying technology, unsuitable for industrial production, reduced electrical properties, etc., and achieves a simple and easy preparation process, less agglomeration, and dispersibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

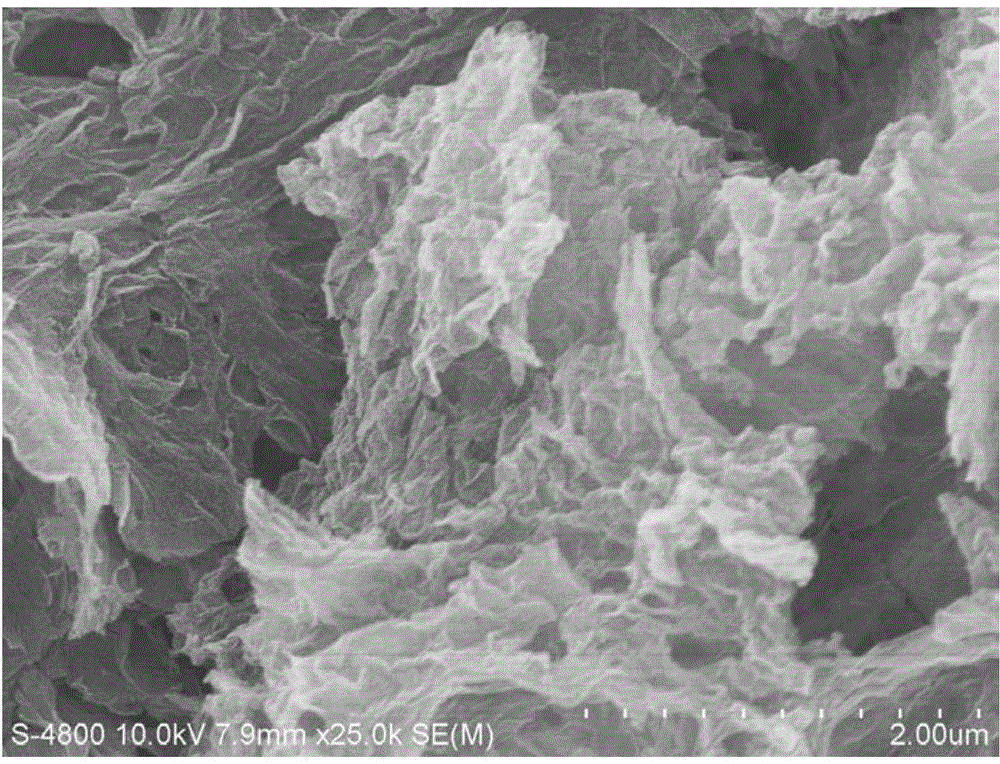

[0032] Example 1 1g of glucose was added to 1000ml of graphene oxide aqueous solution (concentration of 0.2 mg mL -1 ), stirring for 30 minutes, rotating speed 100-300 rev / min. Then 1 ml of aqueous ammonia solution (25-28%) was added and stirring was continued for 2 hours at 95°C. Then add 20mg of CTAB, filter and wash after stirring for ten minutes. Drying under vacuum at 60°C for 12 hours yielded a graphene oxide / glucose mixture. Take 100 mg of graphene oxide / glucose mixture and sonicate it for 30 minutes with a power of 100 W, disperse it in 100 ml of water, add 0.1 ml of pyrrole, stir for 30 minutes, add 0.1 ml of concentrated hydrochloric acid solution, and sonicate for 5 minutes, then add 5 ml of over An aqueous solution of ammonium sulfate (1 mmol) was reacted at 0°C for 2 hours. The product is then filtered, washed and freeze-dried. The product is ammoniated at 700°C for 30 minutes under an atmosphere of argon gas, and the heating rate is 30°C / min. looks like f...

Embodiment 2

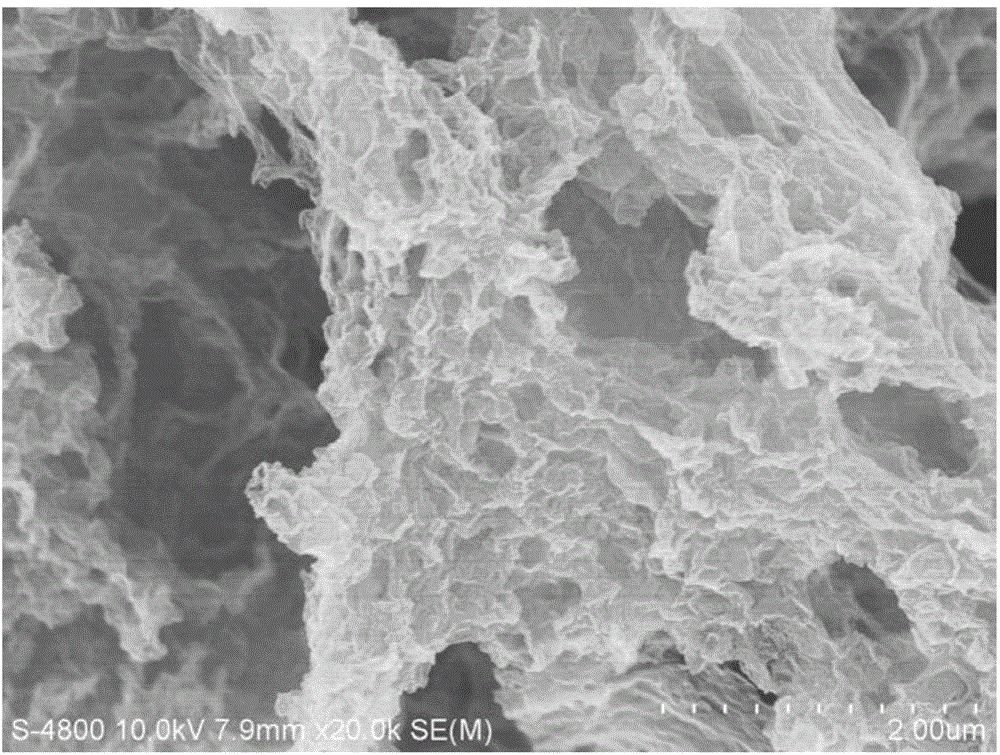

[0033] Example 2 25g of glucose was added to 1000ml of graphene oxide aqueous solution (concentration is 5 mg mL -1 ), stirring for 30 minutes, rotating speed 100-300 rev / min. Then 25 ml of aqueous ammonia solution (25-28%) was added and stirring was continued for 2 hours at 95°C. Then add 500mg of CTAB, filter and wash after stirring for ten minutes. Drying under vacuum at 60°C for 12 hours yielded a graphene oxide / glucose mixture. Take 100 mg of graphene oxide / glucose mixture and sonicate it for 30 minutes with a power of 100 W, disperse it in 100 ml of water, add 0.1 ml of pyrrole, stir for 30 minutes, add 0.1 ml of concentrated hydrochloric acid solution, and sonicate for 5 minutes, then add 5 ml of over An aqueous solution of ammonium sulfate (1 mmol) was reacted at 0°C for 2 hours. The product is then filtered, washed and freeze-dried. The product is ammoniated at 750°C for 30 minutes under an atmosphere of argon gas, and the heating rate is 30°C / min. looks like ...

Embodiment 3

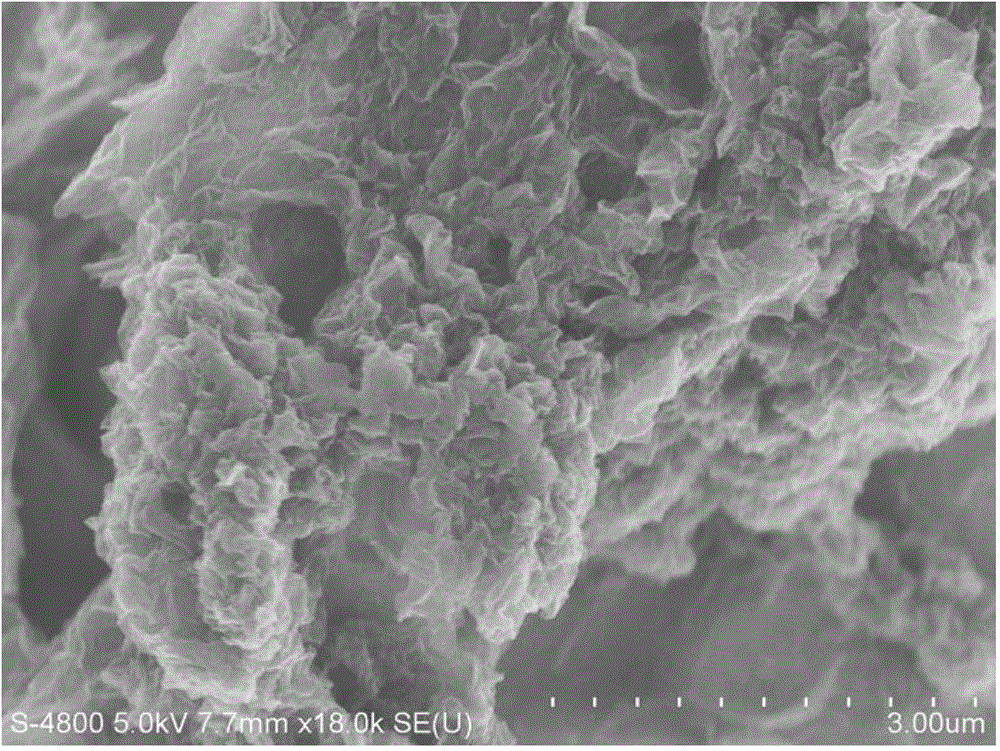

[0034] Example 3 10g of glucose was added to 1000ml of graphene oxide aqueous solution (concentration was 2 mg mL -1 ), stirring for 30 minutes, rotating speed 100-300 rev / min. Then 10 ml of ammonia solution (25-28%) was added and stirring was continued for 2 hours at 95°C. Then add 200 mg of CTAB, filter and wash after stirring for ten minutes. Drying under vacuum at 60°C for 12 hours yielded a graphene oxide / glucose mixture. Take 100 mg of graphene oxide / glucose mixture and sonicate it for 30 minutes with a power of 100 W, disperse it in 100 ml of water, add 0.1 ml of pyrrole, stir for 30 minutes, add 0.1 ml of concentrated hydrochloric acid solution, and sonicate for 5 minutes, then add 5 ml of over An aqueous solution of ammonium sulfate (1 mmol) was reacted at 0°C for 2 hours. The product is then filtered, washed and freeze-dried. The product is ammoniated at 750°C for 30 minutes under an atmosphere of argon gas, and the heating rate is 30°C / min. looks like image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com