Preparation method of magnetic mesoporous silicon dioxide adsorbent for removing aflatoxin in edible oil

A technology of mesoporous silica and aflatoxin, applied in chemical instruments and methods, oil/fat refining, alkali metal oxides/hydroxides, etc. Long time, small specific surface area of particles, etc., to achieve the effect of low raw material cost, high detoxification efficiency, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

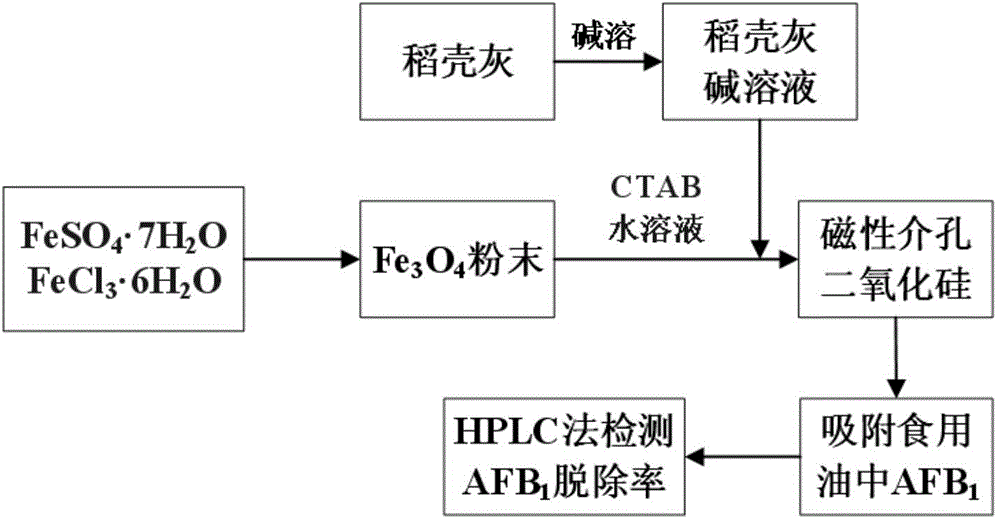

Method used

Image

Examples

Embodiment 1

[0020] (1) Take by weighing 6.4g of rice husk ash and 8.0g of sodium hydroxide solid in a mass ratio of 0.8:1, heat and dissolve in deionized water, and filter with suction, and the filtrate is constant to 250mL to obtain a rice husk ash-alkali solution;

[0021] (2) Add 150mL deionized water and 2mL hydrazine hydrate into a 250mL three-neck flask, stir mechanically for 30min to remove oxygen, and 3+ :Fe 2+ =1.75:1 After adding ferric chloride hexahydrate and ferrous sulfate nonahydrate into the flask, quickly add 8mL ammonia water (v / v=25%), heat to 80°C, and continue stirring for 30min; Wash with absolute ethanol for several times, vacuum dry and grind to obtain magnetic particles;

[0022] (3) Weigh 0.1g of magnetic particles and 0.75g of CTAB into a 500mL beaker, add 2mL of absolute ethanol dropwise, ultrasonically disperse for 30min, mechanically stir at 80°C, add 50mL of rice husk ash-alkali solution, adjust the pH value to 3, maintain the temperature and continue Stir...

Embodiment 2

[0025] (1) Weigh 9.6g of rice husk ash and 8.0g of sodium hydroxide solid at a mass ratio of 1.2:1, add deionized water to dissolve, heat for dissolution, and filter with suction, and the filtrate is constant to 250mL to obtain a rice husk ash-alkaline solution;

[0026] (2) Add 150mL deionized water and 2mL hydrazine hydrate into a 250mL three-neck flask, stir mechanically for 30min to remove oxygen, and 3+ :Fe 2+ =1.75:1 After adding ferric chloride hexahydrate and ferrous sulfate nonahydrate into the flask, quickly add 8mL of ammonia water, heat to 80°C, and continue stirring for 30min; the precipitate is separated by filtration, washed several times with deionized water and absolute ethanol, Vacuum drying and grinding to obtain magnetic particles;

[0027] (3) Weigh 0.15g of magnetic particles and 1.5g of CTAB into a 500mL beaker, add 2mL of absolute ethanol dropwise, ultrasonically disperse for 30min, stir mechanically at 80°C, add 65mL of rice husk ash-alkali solution, ad...

Embodiment 3

[0030] (1) Take by weighing 12.8g of rice husk ash and 8.0g of sodium hydroxide solid in a mass ratio of 1.6:1, add deionized water to heat and dissolve, and filter with suction, and the filtrate is constant to 250mL to obtain a rice husk ash-alkali solution;

[0031] (2) Add 150mL deionized water and 2mL hydrazine hydrate into a 250mL three-neck flask, stir mechanically for 30min to remove oxygen, and 3+ :Fe 2+ =1.75:1 After adding ferric chloride hexahydrate and ferrous sulfate nonahydrate into the flask, quickly add 8mL of ammonia water, heat to 80°C, and continue stirring for 30min; the precipitate is separated by filtration, washed several times with deionized water and absolute ethanol, Vacuum drying and grinding to obtain magnetic particles;

[0032] (3) Weigh 0.2g of magnetic particles and 1.5g of CTAB into a 500mL beaker, add 2mL of absolute ethanol dropwise, ultrasonically disperse for 30min, stir mechanically at 80°C, add 50mL of rice husk ash-alkali solution, adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com