Preparation method for mesoporous hollow spherical TiO2 having high visible light catalysis performance

A technology with catalytic performance and visible light, applied in chemical instruments and methods, physical/chemical process catalysts, titanium dioxide, etc., can solve the problems of increasing the environmental load reaction cost, higher requirements for reaction conditions, long reaction period, etc., to improve the production process. , Increase the adsorption reaction point, overcome the effect of difficult recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

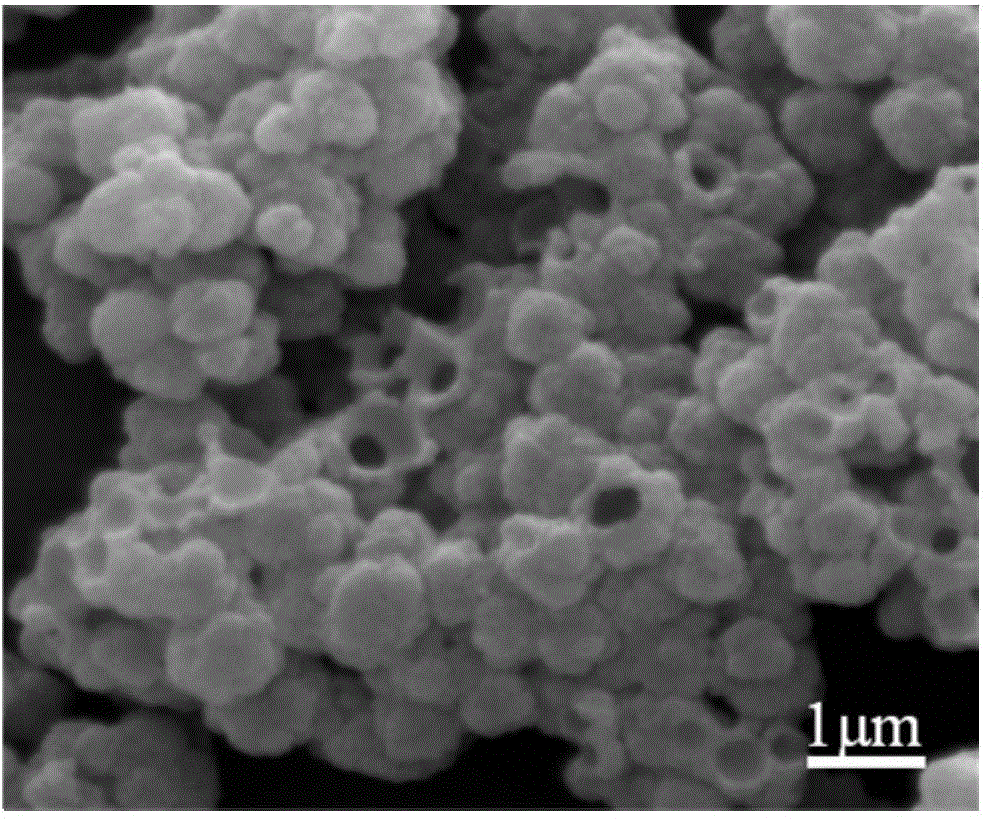

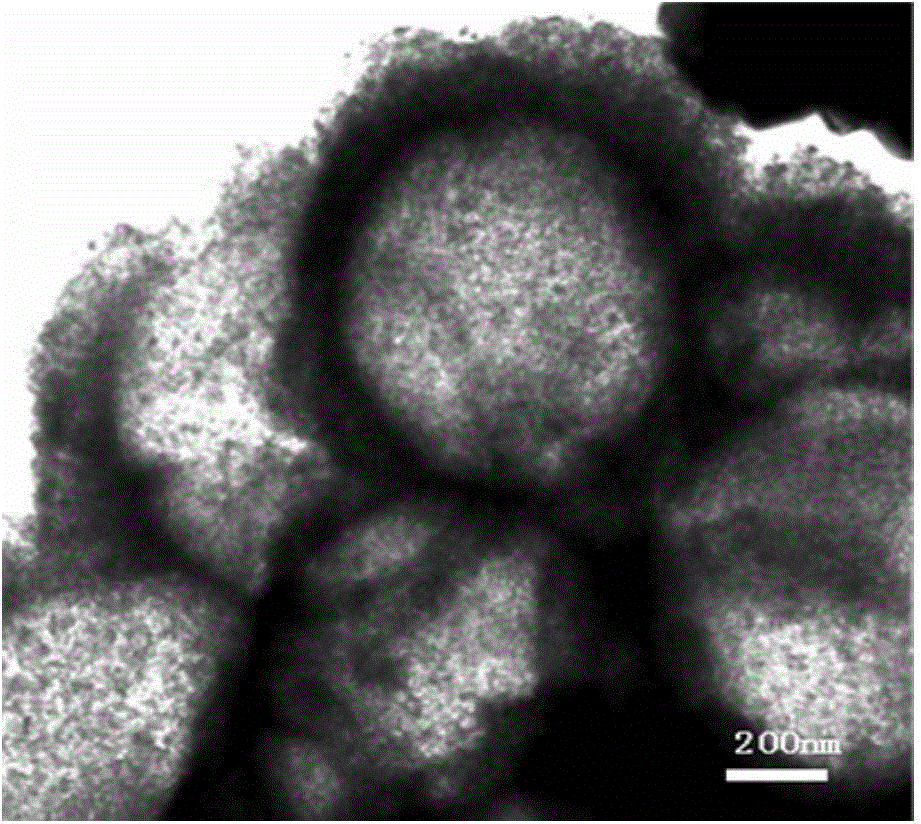

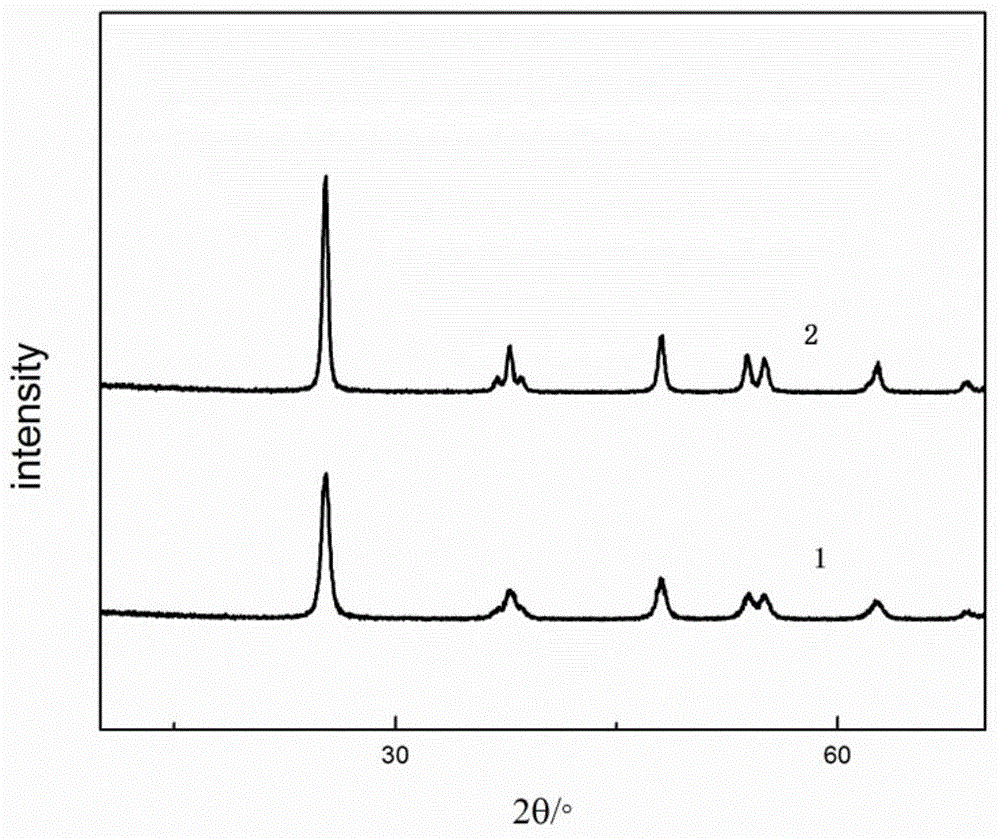

[0025] Put 40mL of 0.6mol / L glucose solution into a polytetrafluoroethylene-lined hydrothermal reaction kettle with a capacity of 50mL, react at 170°C for 7h, and after cooling at room temperature, wash the obtained dark brown solid with distilled water and ethanol Wash until the solution is clear, and dry in an oven to obtain the carbon microsphere template.

[0026] Weigh 1.5g of the above-mentioned carbon spheres and 0.3g of urea, dissolve them in 150mL of distilled water, disperse them evenly by ultrasonic, and take 0.7% TiCl 4 Add dropwise to the above solution, stir at constant temperature in an ice-water bath for 1 hour, add a mixture of ammonium sulfate and hydrochloric acid mL to ensure that the mass ratio of the two is 1:5, continue stirring at high speed for 30 minutes, and then heat up the mixture to 90°C. Adjust the pH to 9, stir at constant temperature for 1 hour, then age at room temperature for 12 hours, wash with distilled water and ethanol until the solution ...

Embodiment 2

[0029] Put 35mL of 0.5mol / L glucose solution into a polytetrafluoroethylene-lined hydrothermal reaction kettle with a capacity of 50mL, react at 190°C for 5h, and after cooling at room temperature, wash the obtained dark brown solid with distilled water and ethanol Wash until the solution is clear, and dry in an oven to obtain the carbon microsphere template.

[0030] Weigh 1.0g of the above carbon spheres and 0.5g of urea, dissolve them in 150mL of distilled water, disperse them evenly by ultrasonic, and take 2% TiCl 4 Add dropwise to the above solution, stir at constant temperature in an ice-water bath for 1 hour, add a mixture of ammonium sulfate and hydrochloric acid mL to ensure that the mass ratio of the two is 1:4, continue stirring at high speed for 2 hours, and then heat up the mixture to 90°C. Adjust the pH to 8.5, stir at constant temperature for 1 hour, then age at room temperature for 12 hours, wash with distilled water and ethanol until the solution is clear, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com